Wireline Operations in Deepwater Well Interventions

Wireline operations are an essential aspect of deepwater well intervention, offering precise and efficient methods for managing and maintaining well integrity. As the industry pushes into deeper waters, the complexity and importance of wireline operations have grown exponentially. This article explores the various facets of wireline operations in deepwater environments, highlighting their types, roles, challenges, technological advancements, and best practices for safe and efficient operations.

What are Wireline Operations?

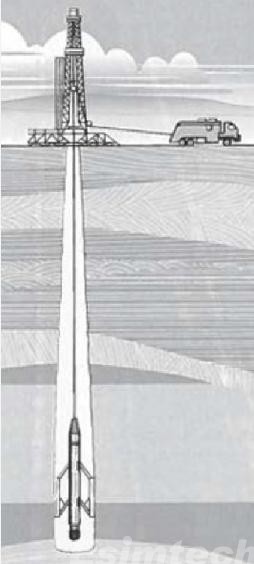

Wireline operations involve the use of a long, thin wire or cable to lower tools and instruments into a wellbore for various purposes, such as data acquisition, well maintenance, and intervention. These operations are important for evaluating well conditions, performing diagnostics, and executing remedial actions without the need for more invasive procedures. Wireline operations are categorized mainly into slickline and electric line (e-line) operations, each serving distinct purposes.

Types of Wireline Operations

1. Slickline Operations

Slickline operations utilize a single-strand, non-electric wire to perform mechanical tasks within the wellbore. The primary applications of slickline operations include:

- Setting and Retrieving Downhole Equipment: This involves placing or removing devices such as plugs, valves, and gauges.

- Mechanical Shifting: Activating or deactivating sliding sleeves and valves to control the flow within the well.

- Fishing Operations: Retrieving lost or stuck equipment from the wellbore.

Slickline operations are favored for their simplicity, cost-effectiveness, and reliability, especially for routine maintenance tasks.

2. Electric Line (E-Line) Operations

Electric line operations use a multi-conductor cable that can transmit electrical power and data between the surface and downhole tools. This capability allows for a wide range of sophisticated applications:

- Logging: Wireline logging tools measure and record physical properties of the formation and fluids in the wellbore. This data is vital for reservoir characterization, helping geologists and engineers make informed decisions about well placement and production strategies. Logging tools can measure parameters such as resistivity, porosity, density, and sonic properties, providing a comprehensive picture of the subsurface environment.

- Perforation: E-line operations deploy perforating guns that use explosive charges to create channels in the casing and cement, connecting the wellbore to the reservoir. This process is critical for initiating production or enhancing existing production by allowing hydrocarbons to flow into the wellbore.

- Intervention: E-line tools can perform various intervention tasks such as setting packers, deploying plugs, and conducting diagnostic tests. These interventions are crucial for maintaining well integrity and addressing issues like blockages or equipment malfunctions.

Role of Wireline Operations in Deepwater Wells

Wireline operations are indispensable in deepwater wells, where the complexity and cost of drilling and production are significantly higher. The precise and accurate data obtained from wireline operations help in:

- Reservoir Evaluation: Comprehensive data from wireline logging is critical for understanding reservoir characteristics, including the distribution and quality of hydrocarbons. This information aids in optimizing production strategies and enhancing recovery rates.

- Well Integrity: Regular wireline checks and maintenance ensure the structural soundness of the wellbore. By identifying and addressing potential issues early, operators can prevent catastrophic failures and maintain continuous production.

- Problem Resolution: Wireline interventions are pivotal in addressing wellbore problems promptly and efficiently. Whether it’s retrieving stuck equipment, clearing blockages, or setting plugs, wireline operations provide the necessary tools and capabilities to resolve issues without extensive downtime.

In summary, wireline operations are vital for the efficient and effective management of oil and gas wells, particularly in challenging deepwater environments. Their ability to provide accurate subsurface data and execute targeted interventions makes them an essential component of modern well intervention strategies.

Challenges in Deepwater Wireline Operations

While wireline operations offer a compelling solution for deepwater interventions, the extreme environment presents several significant challenges that require careful planning and specialized technology.

1. Harsh Environment: Deepwater wells can experience immense pressure exceeding 15,000 psi (pounds per square inch) and temperatures surpassing 250°C (482°F). These conditions can:

Compromise wireline integrity: The immense pressure can cause the wireline to stretch, deform, or even break, leading to tool loss and potential wellbore damage.

Limit tool functionality: Extreme temperatures can affect the performance of downhole tools, impacting the accuracy of data acquisition or hindering the effectiveness of intervention procedures.

Increase equipment wear and tear: The harsh environment accelerates wear on the wireline, tools, and deployment equipment, necessitating frequent maintenance and potentially leading to equipment failure.

2. Remote Location: Deepwater wells are often situated far from shore support facilities. This remoteness translates to:

Logistical complexities: Mobilizing equipment and personnel to the wellsite can be time-consuming and expensive. Weather conditions can further disrupt operations.

Limited resources: Compared to onshore operations, access to spare parts and technical expertise may be restricted on offshore vessels. This necessitates meticulous planning and redundancy measures to ensure smooth operations.

Communication challenges: Reliable communication between the surface crew and downhole tools is crucial. Deepwater environments can introduce signal degradation, potentially hindering real-time data transmission and impacting decision-making.

3. Limited Well Access

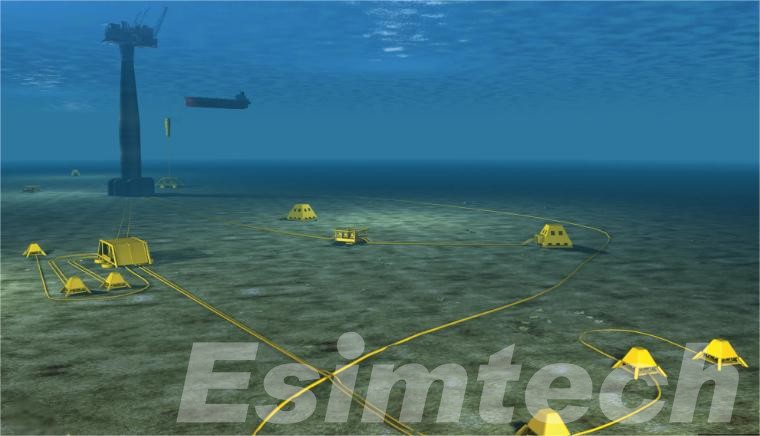

Unlike traditional wellheads readily accessible on land platforms, deepwater wells utilize subsea wellheads located on the seabed. This introduces additional challenges:

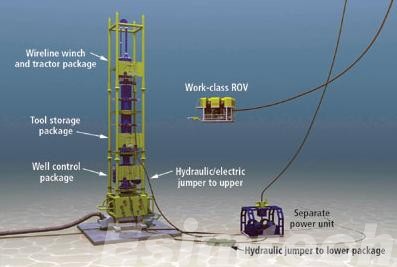

Deployment complexity: Special deployment equipment like ROVs (Remote Operated Vehicles) is required to maneuver the wireline and tools through the complex subsea infrastructure and into the wellbore. This adds another layer of complexity and potential risk to the operation.

Limited wellbore access: Subsea wellheads may have restricted access points compared to onshore wellheads. This can limit the size and type of tools that can be deployed through the wellhead, potentially impacting the range of interventions that can be performed.

By acknowledging these challenges and implementing robust strategies that include advanced technology, meticulous planning, and highly trained personnel, wireline operations can continue to play a vital role in the safe and efficient production of oil and gas from deepwater reserves.

Best Practices for Safe and Efficient Deepwater Wireline Operations

Ensuring safe and efficient wireline operations in deepwater environments requires adherence to rigorous best practices that encompass planning, execution, maintenance, and safety protocols. These practices are essential for mitigating risks, maximizing operational efficiency, and achieving successful outcomes in deepwater well interventions.

Comprehensive Planning

- Risk Assessment: Conducting thorough risk assessments before commencing wireline operations helps identify potential hazards and develop mitigation strategies. Factors such as well complexity, environmental conditions, and equipment reliability should be evaluated.

- Operational Planning: Detailed planning should include scheduling wireline activities during optimal weather conditions to minimize risks associated with strong currents and adverse weather. Coordination with other ongoing operations on the rig is crucial to avoid conflicts and ensure smooth execution.

- Emergency Preparedness: Establishing emergency response procedures and conducting regular drills prepare personnel to respond effectively to unexpected incidents. This includes procedures for equipment failures, personnel injuries, and environmental emergencies.

Training and Competency

- Technical Training: Continuous training programs should be provided to wireline personnel to enhance their technical skills and familiarity with advanced equipment and technologies used in deepwater operations.

- Safety Training: Rigorous safety training is essential for all personnel involved in wireline operations. This includes training in emergency procedures, hazard recognition, personal protective equipment (PPE) use, and offshore survival techniques. Some companies also use simulation technology to provide safety training for employees.

- Certification Requirements: Ensuring that personnel possess relevant certifications and qualifications specific to deepwater wireline operations enhances competence and compliance with industry standards.

Regular Maintenance and Equipment Management

- Equipment Inspection: Conducting regular inspections and maintenance of wireline tools, cables, and associated equipment ensures their reliability and performance in demanding deepwater conditions. This includes corrosion prevention measures and testing under simulated operational environments.

- Spares Inventory: Maintaining an adequate inventory of critical spare parts and tools ensures prompt replacement and minimizes downtime in case of equipment failures or malfunctions.

- Tool Calibration: Periodic calibration of measurement and diagnostic tools is necessary to maintain accuracy and reliability in data acquisition during wireline logging and intervention operations.

Environmental Stewardship

- Environmental Impact Assessment: Conducting environmental impact assessments before wireline operations ensures compliance with regulatory requirements and minimizes the ecological footprint of activities in deepwater environments.

- Waste Management: Implementing proper waste management practices, including the handling and disposal of drilling fluids, chemicals, and other waste materials, mitigates potential environmental hazards and promotes sustainable practices.

- Adoption of Best Available Technology: Embracing technological advancements in wireline tools and equipment that prioritize environmental sustainability, such as low-emission engines and biodegradable lubricants, supports responsible resource extraction.

In conclusion, adhering to these best practices for safe and efficient deepwater wireline operations not only mitigates operational risks but also enhances overall performance and regulatory compliance. By prioritizing comprehensive planning, continuous training, proactive maintenance, effective communication, and environmental stewardship, operators can achieve successful outcomes in deepwater well interventions while safeguarding personnel safety and environmental integrity.

Conclusion

Wireline operations are essential for managing deepwater wells, offering vital data and intervention capabilities that maintain well integrity and productivity. Despite challenges, technological advancements and best practices have notably improved safety and efficiency. As deepwater exploration advances, wireline operations will continue to be pivotal in well interventions, supporting sustainable and profitable hydrocarbon extraction from ocean depths.