Why Use Waterflooding Techniques in Maximizing Oil Recovery

Waterflooding, a secondary oil recovery method, is widely used to enhance oil production in mature fields. By increasing reservoir pressure and displacing residual oil, waterflooding can enhance the recovery factor and prolong the productive life of an oil field. In this article, we explore the fundamentals of waterflooding, various techniques, challenges, and advancements that optimize its application in modern oil reservoirs.

Fundamentals of Waterflooding

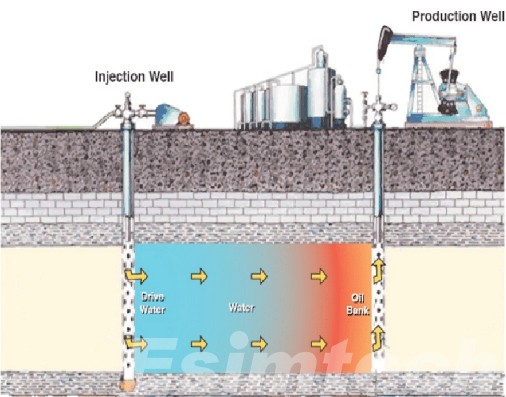

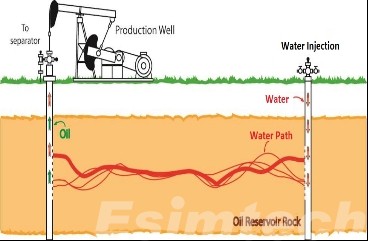

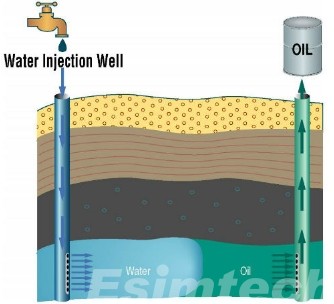

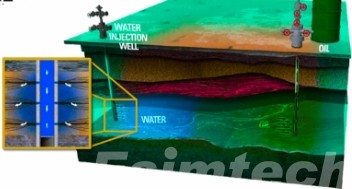

Waterflooding is used once primary recovery methods, relying on natural reservoir pressure, start to decline. The process involves injecting treated water into injection wells, which are often strategically placed around production wells. As water is injected, it helps maintain reservoir pressure, supporting oil mobility within the porous rock. The water flows through high-permeability zones, sweeping oil from regions where oil saturation is higher towards areas connected to production wells.

The success of waterflooding depends on factors such as:

- Reservoir rock permeability and porosity

- Oil viscosity

- Water injection rate and volume

- Reservoir pressure and depth

Common Waterflooding Techniques for Enhancing Oil Recovery

1. Pattern Waterflooding

Pattern water flooding is one of the most traditional methods used to flood a reservoir in a controlled manner. In this technique, injection and production wells are arranged in specific geometric patterns:

- Five-Spot Pattern: Four injection wells are placed at the corners of a square with a single production well in the center.

- Seven-Spot and Nine-Spot Patterns: In these configurations, additional wells are added to increase the density of injection wells, enhancing the sweep of oil toward the production well.

These patterns help create a uniform displacement front, making pattern waterflooding effective in relatively homogeneous reservoirs.

2. Peripheral Waterflooding

In peripheral water flooding, injection wells are located along the reservoir’s perimeter. Water is injected around the edges of the field, displacing oil toward centrally located production wells. This approach is ideal for large fields with well-defined boundaries, as it helps to push oil inward, making peripheral water flooding particularly effective in reservoirs with strong edge-driven water drives.

3. Line Drive Waterflooding

In-line drive waterflooding, injection, and production wells are aligned in parallel lines across the reservoir. Injection wells are placed in a single row opposite a row of production wells, which creates a directional sweep from one side of the field to the other. This technique is especially useful in elongated reservoirs or fields where the rock’s permeability aligns in a specific direction, optimizing the displacement efficiency.

4. Selective Waterflooding

Selective waterflooding, or zonal water flooding, targets specific zones within the reservoir. By injecting water into certain areas, selective water flooding is tailored to reach oil pockets that may otherwise be inaccessible with more traditional flooding techniques. This approach is especially beneficial for reservoirs with high heterogeneity, where different layers or sections have varying permeability or porosity.

5. Gravity-Assisted Waterflooding

Gravity-assisted waterflooding, or gravity drainage waterflooding, uses the natural downward force of gravity to help move water and oil. Typically, water is injected at higher points in the reservoir, and the natural density difference between oil and water helps push the oil toward lower production wells. This method is especially effective in tilted reservoirs or those with vertical thickness and significant differences in density between oil and water.

6. Injection Above and Below Production Wells

In reservoirs with multiple layers or zones of varying permeability, injection above or below production wells can help direct water to specific areas where oil saturation remains high. This technique may involve injecting water into both upper and lower portions of the reservoir to achieve a more balanced sweep and improved oil recovery.

Key Advancements in Waterflooding Techniques for Maximizing Oil Recovery

In recent years, advancements in waterflooding have focused on improving sweep efficiency, minimizing environmental impact, and enhancing oil recovery factors in complex oil reservoirs.

1. Smart Waterflooding

Smart waterflooding integrates real-time data analytics, monitoring systems, and automated controls to optimize water injection. By tracking reservoir performance in real-time, operators can adjust injection rates, manage water breakthroughs, and reduce inefficiencies in the injection process. Smart waterflooding helps balance water injection across zones, minimizing bypassed oil and enhancing overall sweep efficiency.

- Internet of Things (IoT) sensors monitor key metrics such as injection pressure, water cut, and reservoir pressure, allowing operators to make real-time adjustments.

- Automated controls enable precise management of injection parameters, adapting the process to dynamic reservoir conditions without manual intervention.

2. Polymer-Enhanced Waterflooding

Polymer flooding is an enhancement that involves adding polymers to the injected water, which increases its viscosity. The higher viscosity allows the water to sweep the reservoir more evenly, reducing channeling and bypassing in high-permeability zones. This technique is especially effective in reservoirs with heterogeneous rock properties, where conventional waterflooding may fail to recover oil from lower-permeability regions.

- Hydrophobically modified polymers are being used to improve the effectiveness of polymer flooding, as they better adhere to reservoir rock surfaces, enhancing the oil displacement process.

- Cost-effective polymer production has made this technique more economically viable, expanding its use in fields with lower oil prices or challenging production costs.

3. Low-Salinity Waterflooding

Low-salinity waterflooding involves injecting water with a reduced salt concentration. This low-salinity water alters the wettability of the reservoir rock, enhancing oil mobility and facilitating its displacement toward production wells. The method has shown positive results, particularly in carbonate and sandstone reservoirs, where changes in ionic composition can boost oil recovery.

- Reservoir-specific salinity adjustment allows operators to tailor the water’s ionic composition to maximize oil displacement based on the reservoir’s mineralogy.

- Improved understanding of chemical interactions between rock, brine, and oil has enabled precise control of water composition, enhancing the effectiveness of this technique.

4. Surfactant-Enhanced Waterflooding

Adding surfactants to the injection water reduces the interfacial tension between oil and water, making it easier for oil to flow through the reservoir rock. Surfactant-enhanced water flooding is particularly effective in mature fields, where conventional methods have left significant residual oil.

- Biosurfactants are now being used as eco-friendly alternatives, offering comparable performance with reduced environmental impact.

- Customizable surfactant formulas enable tailoring the surfactant properties to match specific reservoir conditions, improving displacement efficiency in different rock types.

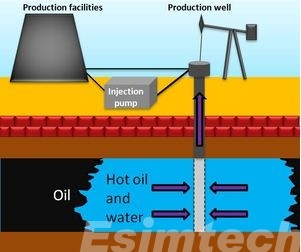

5. Carbonated Waterflooding

Carbonated waterflooding (CWF) involves dissolving CO₂ into the injection water, creating a carbonated solution that can improve oil recovery by decreasing oil viscosity and improving rock wettability. This method combines the benefits of both water and CO₂ flooding, making it effective in both conventional and unconventional reservoirs.

- Improved CO₂ solubility in injection water enhances the efficiency of CWF, allowing for a more uniform displacement front and increasing sweep efficiency.

- Enhanced oil swelling and decreased interfacial tension between oil and water help in mobilizing previously inaccessible oil.

6. Nanotechnology in Waterflooding

Nanotechnology offers a promising frontier in waterflooding, as nanoparticles can be added to the injected water to improve oil displacement by altering rock wettability and reducing interfacial tension.

- Silica and metal oxide nanoparticles are commonly used to change reservoir wettability from oil-wet to water-wet, improving oil flow.

- Nano-enabled tracers allow real-time tracking of fluid movement within the reservoir, providing insights that help optimize water injection strategies.

7. Chemical-Assisted Gravity Drainage (CAGD)

In reservoirs with significant vertical relief, gravity drainage can be an effective mechanism for oil recovery. Chemical-assisted gravity drainage involves injecting chemicals that can enhance the gravity-assisted process by modifying fluid properties, making it easier for oil to drain downwards to production wells.

- Gasified water injections combined with surfactants can help reduce oil viscosity and improve displacement in thick reservoirs.

- Tailored chemical blends help achieve balanced injection across layers, maximizing vertical sweep efficiency and oil drainage.

8. Selective and Controlled Injection Systems

Modern controlled injection systems use intelligent well completions and zonal isolation to manage injection in different reservoir zones. These systems can be selectively controlled to inject water into specific layers, enhancing recovery in challenging or heterogeneous formations.

- Advanced zonal isolation techniques enable targeting of low-permeability zones without over-saturating high-permeability ones.

- Intelligent completions with remote monitoring capabilities allow precise control of injection, reducing water cuts and increasing recovery.

Challenges and Future Outlook in Waterflooding Techniques for Oil Recovery

This chart outlines the primary challenges and highlights potential innovations shaping the future of waterflooding techniques in oil recovery, aiming to make processes more efficient, cost-effective, and environmentally friendly.

| Aspect | Current Challenges | Future Outlook |

| Reservoir Heterogeneity | – Variations in permeability and porosity reduce efficient oil displacement and recovery. | – Enhanced understanding of reservoir geology with 3D imaging and advanced oil simulation technology. |

| Water Quality Management | – Scaling, plugging, and bacterial contamination from poor water quality reduce injection efficiency. | – Advanced water filtration and real-time quality monitoring to prevent blockages and maintain injectivity. |

| Pressure Control | – Balancing injection pressure without damaging the formation or risking blowouts is challenging. | – Smart injection systems and pressure monitoring sensors for optimal reservoir pressure control. |

| Environmental Impact | – Challenges with sourcing injection water, disposal of produced water, and regulatory pressures. | – Closed-loop systems, produced water recycling, and environmentally friendly water sourcing methods. |

| Sweep Efficiency | – Uneven water distribution leads to bypassing oil-rich zones, reducing recovery efficiency. | – Use of “smart” water, polymers, and surfactants to improve water mobility and enhance oil recovery. |

| Economic Viability | – High costs in chemical additives, maintenance, and water sourcing impact the overall economic feasibility. | – Cost-effective additive development, automated monitoring, and better operational efficiency strategies. |

| Corrosion and Scaling | – Corrosive water and scaling agents lead to equipment damage and higher maintenance costs. | – Corrosion-resistant materials, coatings, and continuous monitoring to extend equipment life. |

| Real-Time Data Integration | – Limited access to real-time reservoir data hinders responsive decision-making during operations. | – IoT devices and digital twins for real-time data integration and predictive maintenance. |

In summary, through carefully selecting injection techniques and incorporating advancements in monitoring, chemicals, and digital solutions, waterflooding can continue to evolve as a cost-effective and efficient strategy for maximizing oil recovery. As oil companies increasingly adopt data-driven strategies and customized chemical solutions, it remains a cornerstone for sustainable oil recovery, particularly for maximizing yield from mature fields.