Why Use Hybrid EOR Methods to Maximize Oil Recovery

The oil and gas industry is increasingly turning to advanced methods to maximize oil recovery from existing fields. Hybrid Enhanced Oil Recovery methods have gained significant attention for their ability to extract additional oil that would otherwise remain trapped in the reservoir. By combining different EOR techniques, hybrid EOR methods offer a powerful approach to overcome the limitations of individual methods, resulting in improved efficiency and higher recovery rates.

Understanding EOR Methods

Enhanced Oil Recovery refers to a set of techniques used to increase the amount of oil that can be extracted from a reservoir beyond what is achievable through primary and secondary recovery methods. Primary recovery relies on natural reservoir pressure to drive oil to the surface, while secondary recovery typically involves injecting water or gas to maintain pressure and displace oil. However, even after these methods, a significant portion of the oil (often more than 60%) remains in the reservoir, trapped by capillary forces, reservoir heterogeneity, and other factors.

EOR methods aim to recover this trapped oil by altering the reservoir’s properties or the oil itself, making it easier to extract. Traditional EOR techniques can be broadly classified into three categories:

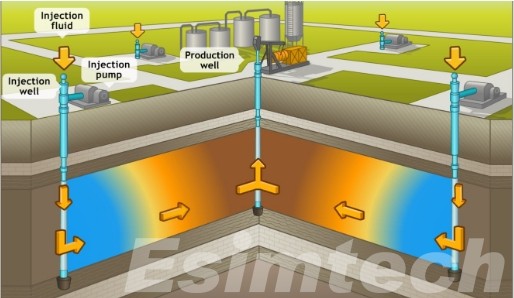

- Thermal EOR Methods: These involve injecting heat into the reservoir, typically through steam injection, to reduce the viscosity of heavy oils, making them flow more easily.

- Chemical EOR Methods: Chemical methods involve injecting chemicals such as polymers, surfactants, or alkaline solutions to alter the surface tension between oil and water, improving oil displacement.

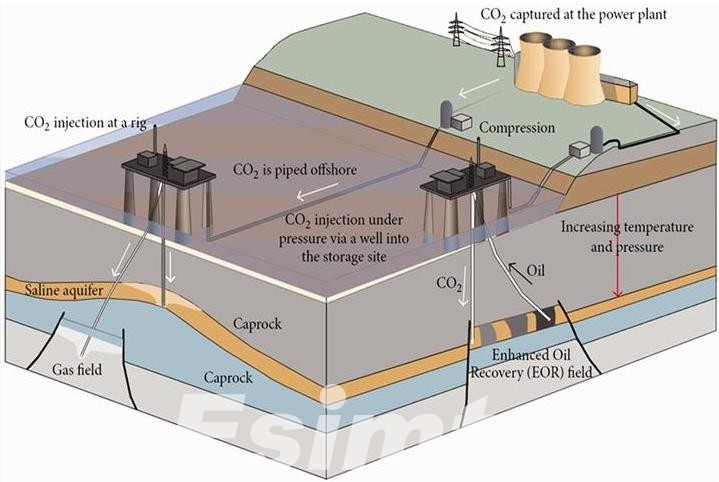

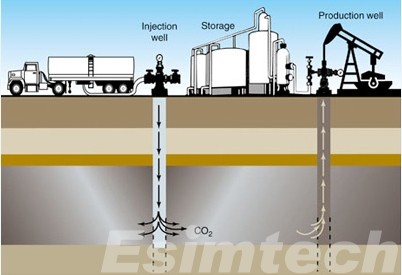

- Gas Injection: This method involves injecting gases such as carbon dioxide (CO2), nitrogen, or natural gas to increase reservoir pressure and enhance oil displacement by either miscible or immiscible flooding.

The Need for Hybrid EOR Methods

While traditional EOR methods have been successful in various contexts, they each have limitations. For instance, thermal methods are highly effective for heavy oil but are less suitable for light oil reservoirs. Chemical methods can be expensive and may suffer from degradation under harsh reservoir conditions. Gas injection methods can be less effective in heterogeneous reservoirs where gas may bypass oil-rich zones.

Hybrid EOR methods seek to address these limitations by combining two or more traditional EOR techniques, leveraging the strengths of each to maximize oil recovery. By doing so, hybrid methods can adapt to the unique characteristics of each reservoir, making them more versatile and effective.

Common Hybrid EOR Methods

Hybrid EOR Methods capitalize on the strengths of each individual technique, addressing the limitations that might arise when using a single method.

1. Thermal-Chemical Hybrid EOR

Overview: This method combines thermal techniques, such as steam injection, with chemical methods like polymer or surfactant flooding.

Mechanism:

- Thermal Component: The steam heats the reservoir, reducing the viscosity of the oil, making it easier to flow.

- Chemical Component: Polymers or surfactants are injected to improve the mobility ratio by increasing the viscosity of the displacing water or by reducing the interfacial tension between oil and water, respectively.

Applications: Particularly effective in heavy oil reservoirs, where high oil viscosity is a primary challenge. The heat from steam makes the oil less viscous, while the chemicals help mobilize and displace the oil more effectively.

2. Gas-Thermal Hybrid EOR

Overview: This method combines gas injection (e.g., CO2) with thermal methods such as steam flooding.

Mechanism:

- Thermal Component: Steam is injected to lower the oil viscosity.

- Gas Component: CO2 or other gases are injected to increase reservoir pressure, enhance oil miscibility, and improve sweep efficiency.

Applications: Suitable for both light and heavy oil reservoirs. The combination of steam and gas injection can address issues related to reservoir heterogeneity and improve overall recovery efficiency.

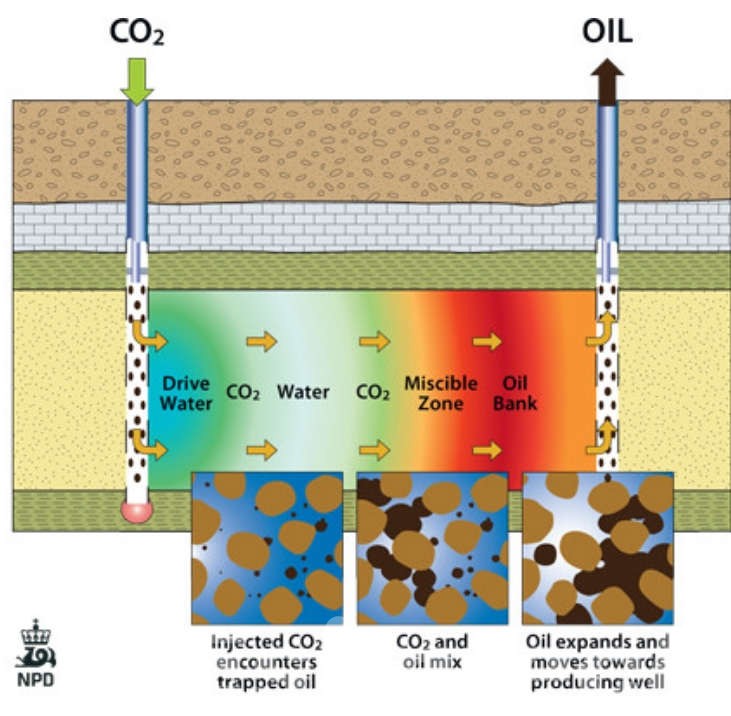

3. Chemical-Gas Hybrid EOR

Overview: In this method, chemical injection (e.g., surfactants or polymers) is combined with gas injection (e.g., CO2 or nitrogen).

Mechanism:

- Chemical Component: Surfactants reduce the interfacial tension between oil and water, while polymers improve the mobility ratio.

- Gas Component: CO2 or nitrogen is injected to either increase pressure or achieve miscible flooding, enhancing oil displacement.

Applications: Effective in reservoirs where the combination of chemical and gas injection can optimize oil mobilization and displacement, particularly in reservoirs with high heterogeneity or challenging fluid properties.

4. Thermal-Gas-Chemical Hybrid EOR

Overview: This is a more complex approach that integrates thermal, gas, and chemical methods to exploit the benefits of each.

Mechanism:

- Thermal Component: Steam or hot water is injected to heat the reservoir and reduce oil viscosity.

- Chemical Component: Surfactants or polymers are used to further mobilize the oil and improve the sweep efficiency.

- Gas Component: CO2 or other gases are injected to increase pressure and enhance oil miscibility or to provide a driving force for oil displacement.

Applications: Ideal for complex reservoirs with diverse oil properties or challenging geological formations. This method can be tailored to address multiple factors simultaneously, improving overall recovery rates.

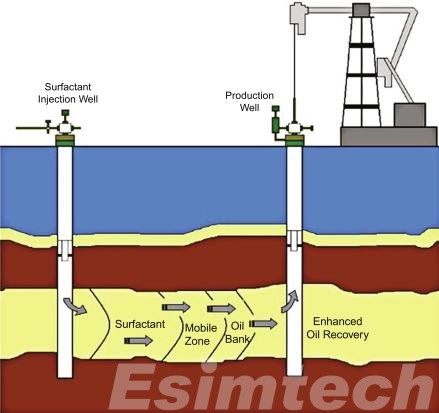

5. Polymer-Surfactant Flooding

Overview: A hybrid method combining polymers and surfactants to improve the displacement of oil.

Mechanism:

- Polymer Component: Increases the viscosity of the displacing water, reducing the mobility of the water phase and improving sweep efficiency.

- Surfactant Component: Lowers the interfacial tension between oil and water, making it easier for the oil to be displaced and mobilized.

Applications: Commonly used in light to medium oil reservoirs where water flooding alone is insufficient due to poor sweep efficiency or high residual oil saturation.

6. Water-Alternating-Gas (WAG) with Chemicals

Overview: The WAG method, which alternates water and gas injection, is enhanced by adding chemicals such as surfactants or polymers.

Mechanism:

- Water-Gas Injection: Alternating water and gas injections help to improve sweep efficiency and reduce gas channeling.

- Chemical Addition: Surfactants or polymers added to the water phase further improve oil displacement and mobility control.

Applications: Suitable for reservoirs where simple gas injection might lead to poor sweep efficiency or where water flooding is limited by unfavorable mobility ratios.

Challenges and Future Outlook in Hybrid EOR Methods

This chart presents a clear and concise overview of the key challenges associated with hybrid EOR methods and the future outlook for overcoming these obstacles.

| Aspect | Challenges | Future Outlook |

| Technical Complexity | – Complex integration of multiple EOR techniques – Requires sophisticated planning and operational coordination | – Advanced reservoir characterization and modeling using AI and data analytics – Development of adaptive and responsive hybrid systems |

| High Costs | – High initial capital expenditure (CAPEX) – Ongoing operational expenses (OPEX) | – Economies of scale reducing costs – Cost-effective chemical formulations and alternative energy sources for thermal methods |

| Reservoir Uncertainty | – Heterogeneity leading to uneven displacement – Fluid incompatibility causing adverse reactions | – Improved reservoir modeling and characterization techniques – Development of nanotechnology and smart materials to optimize recovery |

| Environmental Impact | – Potential contamination from chemicals – Greenhouse gas emissions from thermal methods | – CO2 utilization and storage for combined EOR and carbon sequestration – Adoption of green chemistry techniques and biodegradable polymers |

| Regulatory and Compliance | – Stricter environmental regulations and compliance requirements | – Increased collaboration between industry and regulators for sustainable practices |

| Collaboration and Innovation | – Limited knowledge sharing across the industry | – Industry collaboration and public-private partnerships driving innovation |

How Simulations are Used for Hybrid EOR Methods

Simulations play a crucial role in the planning, design, and optimization of Hybrid Enhanced Oil Recovery methods. By creating virtual models of reservoirs and simulating different EOR methods, engineers can predict the outcomes of various scenarios, optimize processes, and reduce risks before implementing them in the field.

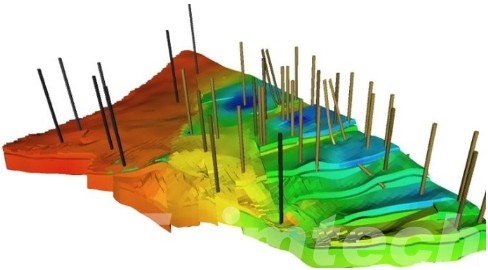

1. Reservoir Characterization and Modeling

- Objective: To create accurate models of the reservoir, including its geology, fluid distribution, and properties.

- Simulation Tools: Geological modeling software, petrophysical models, and fluid flow simulators.

- Application: Simulations help in understanding the reservoir’s heterogeneity, porosity, permeability, and fluid properties, which are critical for selecting the appropriate hybrid EOR method. These models serve as the foundation for further simulations.

reservoir simulation

2. Design and Optimization of EOR Methods

- Objective: To evaluate the effectiveness of different hybrid EOR techniques and optimize their design.

- Simulation Tools: Compositional reservoir simulators, thermal-fluid simulators, and chemical EOR simulators.

- Application: Engineers can simulate various combinations of thermal, chemical, and gas injection techniques to determine the most effective hybrid approach for a specific reservoir. Parameters like injection rates, chemical concentrations, and temperature profiles can be optimized to maximize oil recovery.

3. Predicting Oil Recovery and Economic Viability

- Objective: To forecast the potential oil recovery and assess the economic feasibility of the hybrid EOR method.

- Simulation Tools: Oil recovery simulators, economic evaluation software.

- Application: Simulations can predict the amount of oil that can be recovered using different hybrid methods and estimate the associated costs. This helps in determining the economic viability of the project and making informed decisions on whether to proceed with field implementation.

4. Risk Assessment and Uncertainty Analysis

- Objective: To identify and mitigate risks associated with the implementation of hybrid EOR methods.

- Simulation Tools: Uncertainty quantification models, sensitivity analysis tools, and probabilistic simulation software.

- Application: Simulations allow engineers to perform sensitivity analyses and uncertainty assessments, helping them understand how variations in reservoir properties or operational parameters could impact the success of the hybrid EOR method. This enables proactive risk management and the development of contingency plans.

5. Real-Time Monitoring and Control

- Objective: To monitor the performance of hybrid EOR methods in real-time and make adjustments as needed.

- Simulation Tools: Real-time data integration platforms, digital twins, and predictive analytics.

- Application: Simulations are integrated with real-time data from the field to create digital twins of the reservoir. These digital twins allow operators to monitor the progress of the EOR process, compare it with simulated forecasts, and make adjustments to injection strategies or operational parameters to optimize recovery in real-time.

6. Environmental Impact Assessment

- Objective: To evaluate the environmental impact of hybrid EOR methods and ensure regulatory compliance.

- Simulation Tools: Environmental simulation models, carbon footprint analysis tools.

- Application: Simulations can be used to assess the environmental impact of different hybrid EOR techniques, such as CO2 injection or chemical flooding, by modeling the potential for contamination, emissions, and other environmental risks. This helps in designing EOR strategies that minimize environmental impact and comply with regulatory requirements.

7. Field Pilot Design and Scaling Up

- Objective: To design pilot tests and scale up successful hybrid EOR methods from the lab to the field.

- Simulation Tools: Pilot design simulators, scale-up models.

- Application: Before full-field implementation, simulations are used to design and optimize pilot tests. These pilots help validate the simulation models and gather real-world data that can be used to refine the approach. Successful pilots can then be scaled up, using simulations to guide the transition from pilot to full-field deployment.

Choosing Simulation Tools for Optimizing Hybrid EOR Methods from Esimtech

Esimtech offers advanced simulation tools designed to optimize Hybrid EOR methods. These simulations allow engineers to model complex reservoir conditions, evaluate different combinations of thermal, chemical, and gas injection techniques, and predict oil recovery outcomes. By using Esimtech simulation platforms, operators can tailor hybrid EOR strategies to specific reservoir characteristics, minimize risks, and enhance overall efficiency. The simulations also support real-time monitoring and adjustments, ensuring that hybrid-enhanced oil recovery methods are optimized for maximum recovery and economic viability.