Why Resistivity Logging is Essential in the Oil and Gas Operations

Resistivity logging helps geoscientists and engineers assess potential hydrocarbon reservoirs by measuring the resistivity of rocks and the fluids they contain. This technique is essential in the exploration, drilling, and production phases of oil and gas operations, offering valuable data that guides decision-making throughout the lifecycle of a well.

Principles of Resistivity Logging

Resistivity logging is based on the principle that different materials, such as rocks and fluids, resist the flow of electrical current to varying degrees. Hydrocarbons (oil and gas) are poor conductors of electricity and exhibit high resistivity, while water, especially saline water, is a good conductor with low resistivity. By measuring the resistivity of formations encountered in a borehole, it becomes possible to distinguish between oil and gas reservoirs and water-bearing zones.

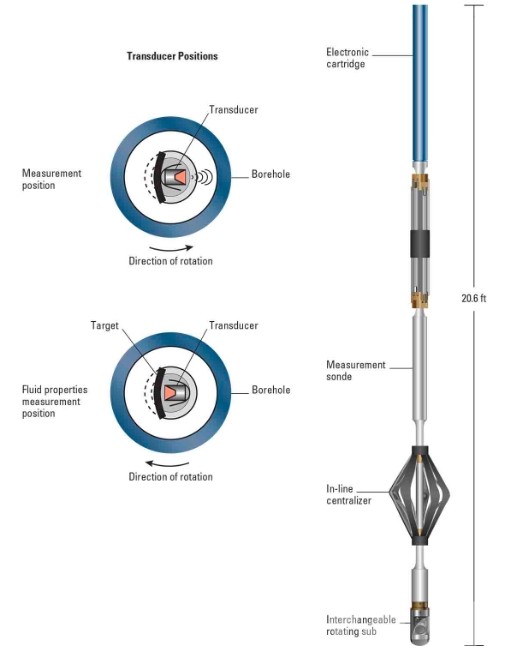

The technique typically involves lowering a tool, known as a resistivity logging tool, into the wellbore. The tool emits an electric current into the formation and measures the voltage response, which is then used to calculate the formation’s resistivity. This data helps to infer the nature of the fluids within the rock pores.

Main Types of Resistivity Logging

There are several types of resistivity logging tools used in the oil and gas industry, each suited to different formation characteristics and drilling environments.

1. Conventional Resistivity Logging

This is the basic method of measuring the electrical resistivity of formations directly surrounding the wellbore. It uses electrodes to emit a current into the formation, and the voltage difference is measured to calculate the resistivity. Conventional resistivity logs provide valuable information about the immediate area around the borehole but have limited penetration depth.

2. Laterolog

Laterolog tools are designed to provide focused resistivity measurements by directing a focused current deeper into formations with high resistivity. These tools are commonly used in formations like tight gas sands and carbonate reservoirs, which have high resistivity. Laterolog tools offer improved accuracy by reducing the effects of borehole fluid invasion and focusing on undisturbed formation.

- Advantages: Improved measurement accuracy in high-resistivity formations.

- Applications: Tight gas sands, carbonate reservoirs.

3. Induction Logging

Induction logging tools are used in non-conductive drilling environments, such as those where oil-based muds are present, or in air-filled wells. Instead of relying on direct current, these tools generate an alternating magnetic field that induces eddy currents in the surrounding formation. The tool measures the secondary magnetic field generated by the eddy currents, which is then used to calculate the formation resistivity.

- Advantages: Suitable for wells with non-conductive drilling fluids, deeper penetration into the formation.

- Applications: Oil-based mud systems, non-conductive environments.

4. Microresistivity Logging

Microresistivity tools provide highly detailed measurements of resistivity near the borehole wall. They are capable of detecting thin bed layers and small-scale features, making them valuable in formations where detailed structural analysis is needed. These tools often use pad-mounted electrodes that make direct contact with the borehole wall.

- Advantages: High resolution, able to detect thin layers.

- Applications: Formation analysis near the borehole, detecting thin beds.

5. Laterally Focused Resistivity Tools

Laterally focused tools aim to measure the true resistivity of the formation by focusing the electric current horizontally, which helps eliminate the influence of borehole fluids or drilling mud invasion. These tools can distinguish between the invaded zone and the undisturbed formation, offering more accurate results in determining formation properties.

- Advantages: Better distinction between invaded and undisturbed zones.

- Applications: Zones with significant mud invasion.

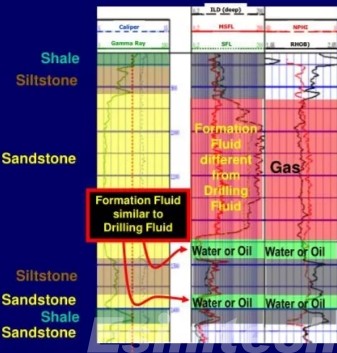

5. Dual Resistivity Logging

Dual resistivity logging tools combine both shallow and deep resistivity measurements. These tools help distinguish between the resistivity of the invaded zone (shallow measurement) and the true formation resistivity (deep measurement). This dual capability makes it easier to assess fluid invasion and the true nature of the formation.

- Advantages: Provides data from both the invaded and uninvaded zones.

- Applications: Evaluation of formations affected by mud filtrate invasion.

6. Focused Induction Resistivity Logging

This method uses advanced focusing techniques to improve the accuracy of resistivity measurements, especially in complex formations. Focused induction tools measure the resistivity at multiple depths and focus the current, reducing the distortion caused by nearby conductive layers or borehole effects.

- Advantages: Improved accuracy in complex formations.

- Applications: Complex lithologies, formations with high heterogeneity.

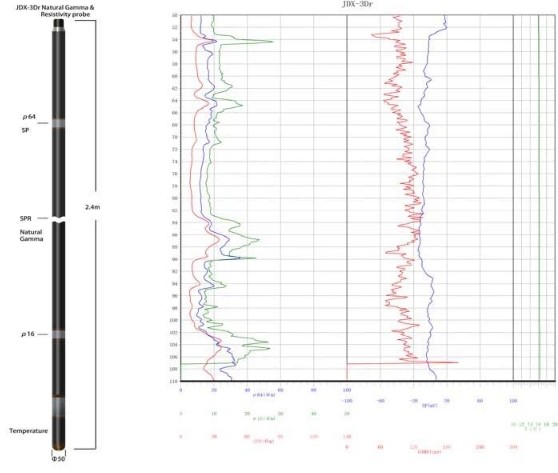

7. Array Induction Logging

Array induction tools measure resistivity at different depths simultaneously, using multiple coils spaced along the tool. This technique provides detailed vertical resolution and allows for the analysis of variations in formation resistivity with depth. It is particularly useful in heterogeneous formations.

- Advantages: Multi-depth measurements for greater vertical resolution.

- Applications: Heterogeneous formations, vertical stratigraphy.

These resistivity logging techniques are often selected based on specific formation characteristics and drilling conditions, offering operators flexibility in gathering detailed subsurface data.

Key Applications of Resistivity Logging in Oil and Gas Industry

- Hydrocarbon Detection: One of the primary functions of resistivity logging is to distinguish between hydrocarbon-bearing formations and water-saturated zones. High resistivity typically indicates the presence of hydrocarbons, whereas lower resistivity suggests water. This helps identify the productive zones that can be targeted for drilling and extraction.

- Formation Evaluation: Resistivity logs are key in determining the lithology and porosity of formations. When combined with other well logging techniques for formation evaluation, such as density or neutron logs, resistivity data provides a clearer picture of the formation’s fluid content, rock type, and potential production capabilities.

- Water Saturation Estimation: By analyzing the resistivity of a formation, geophysicists can estimate the amount of water present in the rock pores. The water saturation level is crucial for calculating the recoverable hydrocarbon reserves, helping operators determine the commercial viability of a reservoir.

- Porosity and Permeability Insights: Resistivity logs, especially when integrated with porosity data from other logs, help in estimating the permeability of the reservoir rock. High resistivity in porous rocks often signals oil or gas presence, whereas lower resistivity might indicate high water saturation or tight formations with poor permeability.

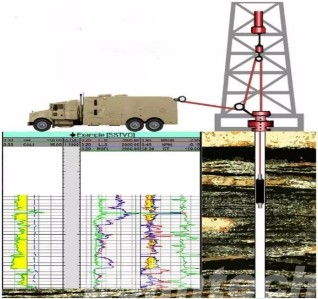

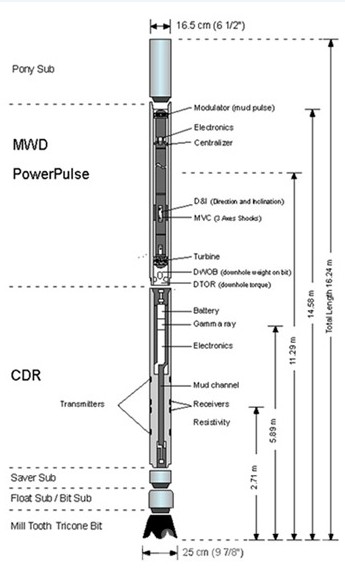

- Well Logging While Drilling (LWD): In modern drilling operations, resistivity logging tools are frequently used in real-time as part of Logging While Drilling (LWD) systems. This integration allows operators to gather crucial data while drilling, enabling them to make immediate decisions regarding well trajectory, drilling speed, and even abandonment or further exploration.

- Monitor Reservoir Depletion: As oil or gas is extracted, the fluid content in the reservoir changes, which can be tracked through changes in resistivity. Resistivity logs allow operators to monitor reservoir depletion and water influx, enabling better management of production.

- Guide Enhanced Oil Recovery (EOR): Resistivity logs help determine the best zones for injection wells in EOR projects. They also provide insights into fluid movement within the reservoir during secondary recovery techniques, such as waterflooding or gas injection.

Challenges in Resistivity Logging

This chart highlights the common challenges encountered during resistivity logging, their impact on data accuracy, and possible strategies for mitigation.

| Challenge | Description | Impact on Logging | Mitigation |

| Formation Anisotropy | Resistivity varies with direction in certain formations (anisotropic behavior). | Can lead to misinterpretation of data, particularly in laminated or fractured formations. | Use advanced tools or algorithms designed for anisotropic formations. |

| Fluid Invasion | Drilling fluids penetrate the formation, altering its natural resistivity. | Affects accurate resistivity readings, especially in the zone near the borehole (invaded zone). | Use dual resistivity tools to compare shallow and deep readings. |

| Complex Lithologies | Heterogeneous formations like interbedded shales, sands, and carbonates. | Difficulties in distinguishing between resistive and conductive materials, complicate log interpretation. | Combine resistivity logs with other logs like gamma-ray or neutron. |

| Borehole Rugosity | Irregular borehole shapes cause poor contact between the logging tool and the formation. | This leads to erroneous resistivity measurements, reducing the accuracy of data. | Employ borehole condition correction techniques and advanced tool designs. |

| Mud Type and Salinity | High salinity muds or conductive drilling fluids affect resistivity readings. | Reduces the accuracy of formation resistivity by introducing external conductivity. | Use induction logging in oil-based or non-conductive environments. |

| Thin Beds | Detection of thin or interbedded layers with different resistivity properties. | Thin layers may not be adequately resolved, leading to an underestimation of resistivity variations. | Utilize high-resolution micro resistivity tools for better thin bed detection. |

| Temperature and Pressure Variations | High temperatures and pressures in deep wells can affect the logging tool’s performance. | Results in errors due to the physical limitations of resistivity tools at extreme conditions. | Use tools designed for high-temperature/high-pressure (HTHP) environments. |

Advances in Resistivity Logging

Advances in resistivity logging have significantly improved the accuracy, resolution, and overall efficiency of well evaluation in the oil and gas industry.

1. Multi-Array Resistivity Tools

- Description: These tools measure resistivity at multiple depths simultaneously, offering a detailed profile of the formation.

- Advantage: Allows for greater vertical resolution, making it easier to identify thin layers and subtle resistivity variations within formations.

- Application: Ideal for heterogeneous reservoirs where high-resolution data is required for better characterization.

2. Logging While Drilling (LWD) with Resistivity

Description: Resistivity logging integrated with the drill string, allowing real-time data collection during drilling operations.

Advantage: Provides immediate resistivity data, enabling real-time decision-making, such as wellbore steering, adjusting the drilling path, or detecting hydrocarbons during drilling.

Application: Used in directional drilling and complex well paths where immediate formation evaluation is crucial.

3. Advanced Induction Logging

Description: Modern induction tools have improved focusing capabilities that reduce interference from borehole fluids or nearby conductive layers.

Advantage: Provides clearer, more accurate resistivity readings in formations with high conductivity contrasts.

Application: Used in wells with oil-based muds or other non-conductive drilling fluids.

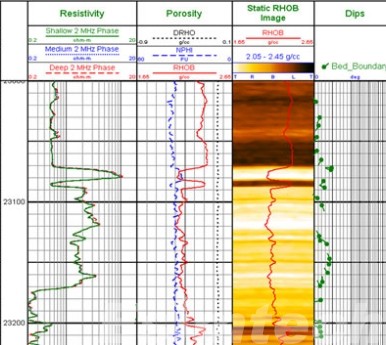

4. Resistivity Imaging Tools

Description: High-resolution microresistivity tools that produce detailed images of the borehole wall, providing structural and lithological data in addition to resistivity measurements.

Advantage: Helps identify fractures, faults, and thin layers with precise detail, giving a clearer picture of the formation.

Application: Commonly used in complex formations with thin bedding or where fracture detection is critical.

5. 3D Resistivity Mapping

- Description: Advanced tools capable of mapping resistivity in three dimensions, giving a more comprehensive view of the surrounding formation.

- Advantage: Provides spatial resistivity data, allowing for the better characterization of complex reservoirs, especially in unconventional resources.

- Application: Used in reservoir modeling and enhanced recovery techniques where 3D visualization of the formation is beneficial.

6. Borehole Imaging Technology Integration

- Description: Integration of resistivity data with borehole imaging tools to create highly detailed cross-sections of the subsurface.

- Advantage: Combines resistivity data with visual images of the formation, offering deeper insights into the structure, porosity, and permeability.

- Application: Beneficial in carbonate formations where resistivity alone may not provide enough data for a full formation analysis.

7. High-Temperature and High-Pressure (HTHP) Tools

- Description: Tools specifically designed to withstand the harsh conditions of deep wells with extreme temperatures and pressures.

- Advantage: Allows for accurate resistivity logging in extreme conditions where traditional tools would fail.

- Application: Essential in deepwater drilling, ultra-deep onshore wells, and geothermal exploration.

8. Deep-Resistivity Logging

- Description: Tools that provide deeper formation penetration, distinguishing between invaded zones and virgin formation more effectively.

- Advantage: Helps overcome issues caused by mud invasion and provides true resistivity readings from undisturbed zones.

- Application: Useful in determining accurate hydrocarbon reserves and formation properties in deep reservoirs.

8. Borehole-Compensated Resistivity Logging

- Description: Tools that compensate for borehole effects, such as variations in mud resistivity or borehole size, to provide more accurate formation resistivity measurements.

- Advantage: Minimizes the effects of drilling fluids and borehole conditions on resistivity readings.

- Application: Used in wells where borehole conditions might interfere with traditional resistivity measurements.

How Simulation Technologies are Used for Resistivity Logging

This chart summarizes the key ways simulation technologies are utilized in resistivity logging to improve accuracy, reduce operational risks, and enhance formation evaluation.

| Simulation Application | Description | Purpose | Benefits |

| Tool Response Simulation | Models tool behavior in different geological conditions and borehole environments. | Evaluate tool performance in varied environments. | Optimizes tool settings, reduces logging errors, and predicts tool performance in different conditions. |

| Formation Resistivity Modeling | Simulates electrical properties of formations, including fluid saturation and porosity. | Predict formation resistivity under varying conditions. | Improves interpretation accuracy by comparing synthetic and actual resistivity logs. |

| Borehole Environment Simulation | Simulates borehole effects such as mud invasion and rugosity on resistivity readings. | Assess how borehole conditions impact measurements. | Identifies and corrects environmental effects, ensuring accurate resistivity data. |

| 3D Reservoir Simulation | Creates detailed 3D models of reservoirs simulations integrating resistivity data with other subsurface data. | Visualize resistivity distribution in the reservoir. | Enhances hydrocarbon identification and assists in well planning and reservoir management. |

| Mud Invasion Simulation | Models the impact of mud filtrate invasion on formation resistivity near the borehole. | Predict effects of invasion on resistivity readings. | Distinguishes between invaded and virgin zones, improving hydrocarbon saturation estimates. |

| Real-Time Data Simulation | Digital twins simulate real-time well logging operations to compare with real-time data. | Validate and troubleshoot real-time logging. | Enables real-time decision-making and operational adjustments, improving logging efficiency. |

| Advanced Interpretation Algorithms | Combines simulation with AI/ML algorithms to interpret resistivity data more efficiently. | Automate resistivity log interpretation. | Reduces interpretation time and errors, enhances data accuracy in complex formations. |

| Sensitivity Analysis | Simulates how changes in formation parameters affect resistivity measurements. | Identify key parameters affecting resistivity. | Prioritizes critical parameters, optimizing logging operations and enhancing data accuracy. |

| Cross-Disciplinary Integration | Integrates resistivity simulations with other geological/geophysical simulations. | Combine resistivity data with other subsurface data. | Provides comprehensive reservoir characterization, improving well placement and resource estimation. |

In summary, resistivity logging is an indispensable tool in the oil and gas industry, providing essential data for exploration, well planning, and production optimization. As technology continues to advance, resistivity logging is becoming even more precise, enabling operators to unlock challenging resources and maximize recovery from increasingly complex reservoirs. Adopting simulation technologies, oil and gas operators can predict tool behavior, optimizing data collection, mitigating logging challenges and improving the overall accuracy of formation evaluation.