Why Choose the Integration of Top Drive Systems with Other Drilling Systems

The oil and gas drilling industry has seen significant technological advancements over the years, and one of the most transformative developments is the integration of top drive systems with other drilling systems. This integration is crucial for enhancing drilling efficiency, safety, and operational capabilities. This article explores the integration of top drive systems with other drilling systems and how this synergy enhances modern drilling operations.

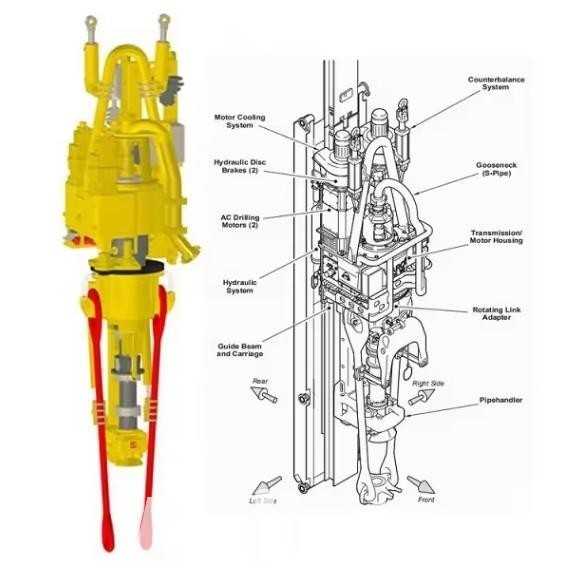

Understanding Top Drive Systems

Here’s a chart summarizing key aspects of understanding top drive systems.

| Aspect | Description |

| Definition | A top drive system is a mechanical device used in drilling rigs to rotate the drill string and drill bit from the top. |

| Components | Motor: Provides the rotational force. Drive Shaft: Transmits rotation to the drill string. Torque Wrench: Allows for making and breaking connections. Control System: Manages operations and ensures safety. |

| Functions | Rotates the drill string and drill bit. Facilitates directional drilling. Makes and breaks drill pipe connections automatically. Provides better control over drilling parameters. |

| Advantages | Efficiency: Enables continuous drilling and reduces non-productive time. Safety: Reduces the need for manual handling, decreasing the risk of accidents. Flexibility: Supports various drilling techniques, including directional and horizontal drilling. Torque Control: Provides precise control over the torque applied to the drill string. |

| Applications | Onshore and offshore drilling operations. Conventional vertical drilling.Horizontal and directional drilling. Deepwater and ultra-deepwater drilling. |

| Types | Electric Top Drives: Powered by electric motors, offering precise control and lower maintenance. Hydraulic Top Drives: Powered by hydraulic systems, known for their robustness and high torque capabilities. |

| Operational Process | Initiation: The top drive is positioned at the top of the drill string. Rotation: The motor rotates the drive shaft, turning the drill string and bit. <br> – Connection: The torque wrench makes and breaks connections as needed during the drilling process. Control: The control system monitors and adjusts operational parameters to optimize performance. |

| Future Trends | Increased automation and use of AI for real-time monitoring and optimization. Integration with digital twins for predictive maintenance and operational efficiency. Development of more energy-efficient and environmentally friendly systems. |

Integrating Top Drive Systems with Other Drilling Systems

1. Drilling Control Systems

- Automation and Monitoring: Integrating top drives with advanced drilling control systems enables automated monitoring and control of drilling parameters. This includes real-time adjustments to torque, weight on bit, and rotational speed, optimizing drilling performance.

- Data Integration: Enhanced data integration allows for better analysis and decision-making, leading to improved drilling efficiency and reduced downtime.

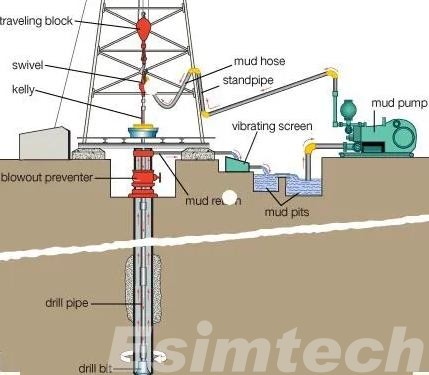

2. Blowout Preventer (BOP) Systems

- Safety Synchronization: The integration ensures that the top drive system can quickly respond to signals from the blowout preventer system during emergency situations, such as kicks or blowouts, enhancing well control and safety.

- Operational Coordination: Seamless coordination between the top drive and BOP systems ensures smooth operations during drilling and tripping activities, reducing the risk of well control incidents.

3. Mud Systems

- Efficient Mud Circulation: Integrated systems ensure efficient mud circulation, which is crucial for wellbore stability, cuttings removal, and maintaining hydrostatic pressure.

- Real-Time Monitoring: Real-time monitoring of mud properties and flow rates helps in adjusting drilling parameters on the fly, optimizing performance and preventing issues such as stuck pipe or formation damage.

4. Downhole Tools

- Directional Drilling Tools: Integration with measurement-while-drilling (MWD) and logging-while-drilling (LWD) tools enhances the ability to steer the wellbore accurately, improving well placement and reservoir contact.

- Vibration Management: Coordinating with vibration management tools reduces drill string vibrations, preventing damage to the drill string and downhole equipment.

Challenges and Solutions in the Integration of Top Drive Systems with Other Drilling Systems

1. Compatibility Issues

Challenge

- Varying standards and protocols among different drilling systems and equipment can cause compatibility problems, making integration complex and inefficient.

Solutions

- Adopt Industry Standards: Encourage the adoption of industry-wide standards to ensure compatibility between different systems and equipment.

- Use Compatible Interfaces: Implement interfaces and communication protocols that facilitate seamless integration between top drive systems and other drilling systems.

2. Complex Synchronization

Challenge

- Synchronizing the operations of top drive systems with other drilling components, such as blowout preventers (BOPs) and drilling mud systems, can be intricate and technically challenging.

Solutions

- Advanced Control Algorithms: Develop and deploy advanced control algorithms that ensure smooth and efficient synchronization of operations.

- Integrated Control Systems: Utilize integrated control systems that can manage multiple components simultaneously, ensuring coordinated operations.

3. Data Management

Challenge

- The integration process generates large volumes of data that need to be effectively managed and analyzed. Ensuring data security and accessibility is also critical.

Solutions

- Robust Data Management Systems: Implement robust data management systems that can handle large datasets, ensuring data is organized and accessible.

- Cybersecurity Measures: Apply stringent cybersecurity measures to protect sensitive data from unauthorized access and cyber threats.

4. Training and Skill Development

Challenge

- Operators and technicians need specialized knowledge and skills to effectively manage and maintain integrated systems, requiring extensive training.

Solutions

- Comprehensive Training Programs: Develop comprehensive training programs that cover all aspects of operating and maintaining integrated drilling systems.

- Ongoing Skill Development: Offer continuous education and skill development opportunities to keep personnel up-to-date with the latest technologies and practices.

5. Initial Investment Costs

Challenge

- The cost of acquiring and integrating advanced top drive systems with other drilling systems can be high, posing a financial challenge for many companies.

Solutions

- Cost-Benefit Analysis: Conduct thorough cost-benefit analyses to demonstrate the long-term savings and efficiency gains from integration.

- Phased Implementation: Consider phased implementation strategies to spread out costs and allow for incremental investments over time.

5. Operational Disruptions

Challenge

Integrating new systems can lead to temporary downtime and disruptions in ongoing operations, affecting productivity.

Solutions

- Scheduled Integration: Plan the integration process during scheduled maintenance periods to minimize disruptions to regular operations.

- Pilot Testing: Conduct pilot testing on a smaller scale before full implementation to identify and address potential issues without major operational impacts.

6. Maintenance and Upgrades

Challenge

Keeping up with technological advancements requires regular maintenance and periodic upgrades, which can be resource-intensive.

Solutions

- Regular Maintenance Schedules: Establish regular maintenance schedules to ensure systems are kept in optimal condition.

- Upgrade Plans: Develop long-term upgrade plans that account for future technological advancements and budget for necessary updates.

7. Standardization Gaps

Challenge

- Lack of standardization in equipment and software can lead to integration difficulties and operational inefficiencies.

Solutions

- Promote Standardization: Advocate for industry-wide standardization and interoperability frameworks to facilitate easier integration.

- Collaborative Efforts: Engage in collaborative efforts with equipment manufacturers and other stakeholders to develop and adopt standardized solutions.

8. Real-Time Data Integration

Challenge

Integrating real-time data from various systems requires significant computing resources and can be technically challenging.

Solutions

- High-Performance Computing: Utilize high-performance computing resources to manage and process real-time data efficiently.

- Real-Time Analytics Platforms: Implement real-time data analytics platforms that can provide immediate insights and facilitate quick decision-making.

9. Operational Flexibility

Challenge

- Ensuring that the integrated system is flexible enough to adapt to different drilling conditions and requirements can be challenging.

Solutions

- Modular Design: Design systems with modular and scalable architecture to allow for flexibility and adaptability in various operational conditions.

- Customizable Solutions: Offer customizable solutions that can be tailored to specific drilling environments and requirements.

Simulation Technology Used in the Integration of Top Drive Systems with Other Drilling Systems

Simulation technology plays a crucial role in the integration of top drive systems with other drilling systems. It helps in designing, testing, and optimizing the performance of these integrated systems before they are deployed in real-world scenarios.

1. Virtual Prototyping and Testing

Description

Virtual prototyping allows engineers to create detailed digital models of top drive systems and their integration with other drilling systems. These prototypes can be tested under various conditions to evaluate their performance without the need for physical prototypes.

Benefits

- Cost Savings: Reduces the need for expensive physical prototypes.

- Speed: Accelerates the design and testing phases.

- Risk Mitigation: Identifies potential issues early in the design process.

2. Finite Element Analysis (FEA)

Description

FEA is used to simulate the physical behavior of components and systems under various conditions. It helps in understanding how the top drive system and other drilling components will respond to stresses, vibrations, and other forces.

Benefits

- Stress Analysis: Evaluates the structural integrity of components.

- Optimization: Helps in optimizing design for durability and performance.

- Predictive Maintenance: Identifies potential failure points and maintenance needs.

3. Computational Fluid Dynamics (CFD)

Description

CFD simulations are used to model and analyze fluid flow within the drilling systems. This includes the behavior of drilling mud, the cooling and lubrication of the drill bit, and the removal of cuttings from the wellbore.

Benefits

- Efficiency: Optimizes fluid dynamics for improved drilling efficiency.

- Problem Identification: Detects issues such as turbulence or improper fluid flow that could lead to operational problems.

- Performance Improvement: Enhances the performance of the mud system and other fluid-related components.

4. Dynamic Simulation

Description

Dynamic simulation involves creating time-based models to simulate the behavior of the drilling system over time. This top drive drilling simulation system includes the interaction between the top drive, drill string, and downhole tools.

Benefits

- Operational Insights: Provides insights into the dynamic behavior of the system during drilling operations.

- Optimization: Helps in optimizing operational parameters such as rotational speed and weight on bit.

- Real-Time Decision Making: Supports real-time decision-making by predicting system behavior under various conditions.

5. Control System Simulation

Description

Simulating the control systems used in drilling operations ensures that the integration between the top drive system and other control systems is seamless. This includes the coordination of the top drive with the blowout preventer (BOP), mud pumps, and other critical components.

Benefits

- System Integration: Ensures smooth integration and operation of various control systems.

- Fault Detection: Identifies potential faults and control system issues before deployment.

- Performance Tuning: Allows for fine-tuning of control algorithms for optimal performance.

6. Virtual Reality (VR) and Augmented Reality (AR)

Description

VR and AR technologies are used to create immersive simulations for training and operational planning. These simulations can model the entire drilling environment, allowing operators to interact with the system in a virtual setting.

Benefits

- Training: Provides realistic training scenarios for operators without the risk of real-world consequences.

- Operational Planning: Aids in planning complex operations by visualizing them in a virtual environment.

- Safety: Enhances safety by allowing operators to practice emergency procedures in a simulated environment.

Conclusion

The integration of top drive systems with other drilling systems represents a significant advancement in modern drilling operations. By enhancing efficiency, improving safety, and providing greater operational flexibility, this integration is reshaping the landscape of the oil and gas industry.