What You Need to Know about Deepwater Well Logging

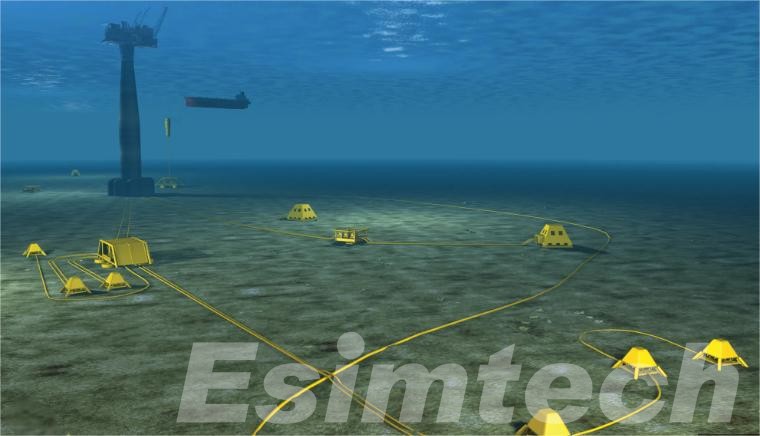

As the oil and gas industry explores resources in ever-deeper waters, deepwater well logging plays a pivotal role in ensuring successful operations. This specialized technique involves collecting detailed subsurface data from deepwater wells, enabling operators to evaluate reservoirs, optimize drilling strategies, and enhance safety measures in deepwater oil and gas exploration.

Understanding Deepwater Well Logging

Well logging is the process of recording measurements within a borehole to understand the geological formations encountered during drilling. In deepwater contexts, these operations take place beneath thousands of meters of water and seabed, where extreme pressures, low temperatures, and logistical challenges define the environment.

Deepwater well logging not only helps in identifying hydrocarbon-rich zones but also aids in predicting formation behavior, ensuring well integrity, and improving the economic viability of offshore projects.

Key Objectives of Deepwater Well Logging

- Reservoir Evaluation: Logging provides insights into the porosity, permeability, and fluid content of geological formations, helping operators identify potential hydrocarbon reservoirs.

- Formation Integrity Analysis: Data collected during logging assists in determining the strength and stability of formations, which is crucial for safe drilling and wellbore stability.

- Fluid Characterization: Logging tools can differentiate between oil, gas, and water within the formation, enabling accurate reserve estimations.

- Geological Mapping: Logs help create detailed geological models of the subsurface, aiding in the planning of optimal well paths.

Key Techniques and Tools Used in Deepwater Logging

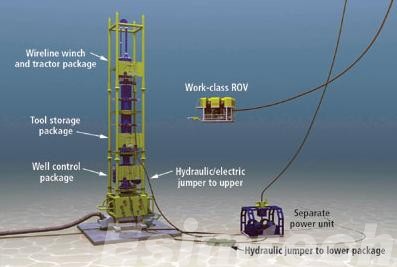

1. Wireline Logging

Wireline logging is a widely used technique where tools attached to a cable are lowered into the wellbore to gather continuous measurements. Key features of wireline logging include:

- Gamma Ray Logging: Measures natural radiation emitted by formations to differentiate between shale and sand or carbonate rocks. This is essential for identifying reservoir zones.

- Resistivity Logging: Detects hydrocarbon-bearing zones by measuring the resistance of rock formations to electrical current flow. Hydrocarbons are typically more resistive compared to water-saturated zones.

- Sonic Logging: Uses sound waves to evaluate formation porosity and mechanical properties, aiding in wellbore stability and fracture identification.

- Density and Neutron Logs: Measure the bulk density and hydrogen content of formations to infer porosity and fluid types within the rock.

2. Logging While Drilling (LWD)

Logging While Drilling (LWD) integrates measurement tools into the drill string, enabling real-time data acquisition during drilling operations. Key advantages include:

- Real-Time Data Acquisition: Provides immediate insights into formation properties, allowing operators to adjust drilling parameters on the fly.

- Resistivity-at-the-Bit: Measures resistivity near the drill bit to detect formation boundaries and avoid drilling into unwanted zones.

- Formation Pressure and Mobility: Offers real-time pressure readings, helping to evaluate formation fluid dynamics and reservoir connectivity.

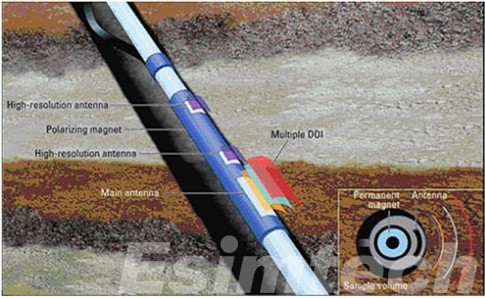

3. Nuclear Magnetic Resonance (NMR) Logging

NMR logging is a sophisticated technique that uses magnetic fields and radio waves to assess fluid properties within pore spaces. It provides:

- Porosity and Permeability Estimates: Measures the volume and mobility of fluids within rocks, offering direct insights into reservoir quality.

- Fluid Type Identification: Distinguish between oil, gas, and water without relying on resistivity contrasts.

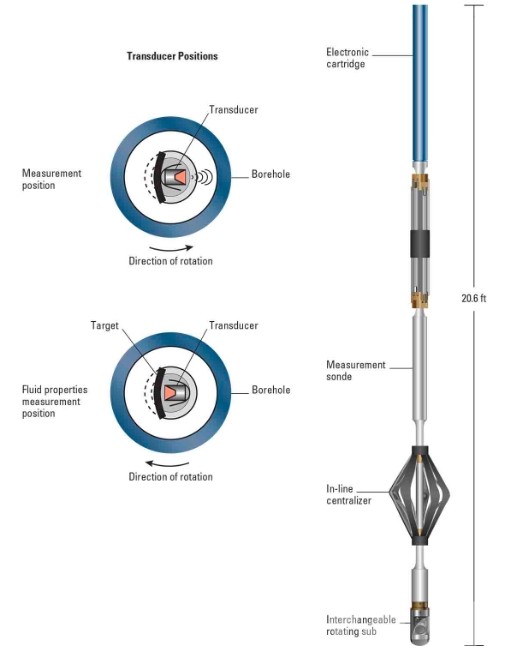

4. Borehole Imaging

Borehole imaging tools capture high-resolution visuals of the wellbore wall, revealing geological and structural features. Popular imaging techniques include:

- Acoustic Imaging: Uses sound waves to create detailed images of borehole features, such as fractures and bedding planes.

- Electrical Imaging: Electrical currents are employed to generate images that highlight changes in formation conductivity, aiding in structural and stratigraphic analysis.

5. Deep Imaging and Seismic Logging

Deep imaging tools extend the depth of investigation beyond the borehole, offering broader subsurface insights:

- Borehole Seismic Logging: Combines wellbore and surface seismic data to create detailed maps of reservoir structures and identify potential hydrocarbon traps.

- Cross-Well Tomography: Uses seismic signals transmitted between wells to generate high-resolution images of the subsurface.

6. Pressure and Temperature Tools

These tools are essential for understanding reservoir behavior in deepwater environments:

- Formation Pressure Tools: Measure fluid pressure within the formation, aiding in reservoir characterization and well control.

- Temperature Logging Tools: Monitor temperature profiles in the well, providing insights into fluid movements and thermal gradients.

Challenges in Deepwater Well Logging

This chart summarizes the multifaceted challenges encountered in deepwater well logging and highlights strategies to mitigate their impact, ensuring safer and more efficient operations.

| Challenge | Description | Impact | Mitigation Strategies |

| Extreme Environmental Conditions | High pressures, low temperatures, and corrosive fluids require robust tool design. | Equipment failure reduced reliability. | Use of high-strength materials and advanced tool designs. |

| High Operational Costs | Offshore operations involve expensive equipment, logistics, and personnel. | Increased financial burden; limits deployment in marginal fields. | Optimize tool usage through integrated systems; adopt autonomous and reusable tools. |

| Complex Data Interpretation | Diverse data sets from multiple tools require advanced interpretation techniques. | Delayed decisions, and potential errors in reservoir evaluation. | Implement AI and machine learning for real-time data integration and analysis. |

| Tool Malfunctions | Stuck tools, electrical failures, or damage due to harsh conditions. | Disruptions to operations; added costs for retrieval or replacement. | Routine maintenance, tool health monitoring, and contingency planning. |

| Remote Offshore Location | Limited access to resources and personnel in deepwater sites. | Delays in repairs or tool replacement; extended downtime. | Utilize remote monitoring and automated systems; stock critical spare parts offshore. |

| Safety Risks | A high-risk environment with potential for blowouts or accidents. | Threats to personnel and environmental damage. | Strict safety protocols, enhanced real-time monitoring, and emergency response systems. |

| Geological Uncertainty | Unexpected subsurface conditions, such as complex faults or formations. | Inaccurate reservoir estimates; drilling inefficiencies. | Use advanced seismic data and pre-drill simulations to refine expectations. |

| Operational Challenges | Navigating tight wellbore spaces or drilling in unstable formations. | Increased likelihood of non-productive time (NPT). | Develop adaptable drilling strategies with real-time logging data. |

Innovations in Deepwater Logging

1. Real-Time Data Acquisition and Transmission

Innovations

- Advanced telemetry systems transmit data from the wellbore to the surface in real time.

- Fiber optic and electromagnetic telemetry enable faster data transfer over long distances.

Benefits

- Immediate access to logging data allows for on-the-fly decision-making.

- Reduces the need for separate logging runs, saving time and costs.

2. Autonomous Logging Tools

Innovations

- Development of self-powered, programmable logging tools that can operate independently.

- Tools equipped with advanced navigation and self-correction systems for accurate deployment.

Benefits

- Reduces reliance on human intervention in high-risk environments.

- Minimizes downtime caused by tool failures or deployment issues.

3. Integration of Logging While Drilling (LWD) with Artificial Intelligence

Innovations

- AI-powered algorithms analyze real-time LWD data to predict formation properties and potential hazards.

- Machine learning identifies trends and anomalies to enhance data interpretation.

Benefits

- Improves drilling efficiency and safety by anticipating formation behavior.

- Reduces human error in data analysis.

4. High-Temperature and High-Pressure (HTHP) Tools

Innovations

- HPHT well tools are designed with enhanced materials, such as ceramics and high-strength alloys, to withstand extreme conditions.

- Advanced cooling systems and pressure-sealing technologies.

Benefits:

- Enables logging in ultra-deepwater environments where traditional tools would fail.

- Increases operational reliability and reduces tool failures.

5. Nuclear Magnetic Resonance (NMR) Enhancements

Innovations

- Miniaturized NMR tools are suitable for narrow-diameter wells.

- Advanced signal processing for improved resolution and accuracy.

Benefits

- Provides more precise measurements of porosity, permeability, and fluid content.

- Reduces the need for additional logging runs.

6. Borehole Imaging Advancements

Innovations

- High-resolution imaging tools with 360° coverage and enhanced depth of investigation.

- Combined acoustic and electrical imaging for more detailed subsurface visualization.

Benefits

- Delivers detailed fracture and fault analysis for better reservoir characterization.

- Improves drilling trajectory planning and wellbore stability.

7. Compact Multi-Measurement Tools

Innovations

- Integration of multiple sensors into a single compact tool, reducing the need for separate deployments.

- Advanced calibration systems for simultaneous measurement accuracy.

Benefits

- Reduces operational time and costs.

- Enhances data coherence by eliminating discrepancies between separate tool measurements.

8. Environmental Sensors

Innovations

- Sensors capable of detecting methane leaks and monitoring pressure changes in real time.

- Development of eco-friendly tools with reduced environmental impact.

Benefits

- Enhances safety and reduces environmental risks.

- Aligns with sustainability goals and regulatory requirements.

9. Digital Twins and Virtual Logging Simulations

Innovations

- Creation of digital twins for logging tools and subsurface environments.

- Virtual well logging simulations optimize tool design and pre-deployment testing.

Benefits

- Reduces the risk of tool failure by identifying potential issues before deployment.

- Saves costs by optimizing tool usage and design.

Overall, deepwater well logging is critical in offshore oil and gas exploration. Though providing unparalleled insights into the subsurface, it empowers operators to unlock the full potential of deepwater reservoirs while mitigating risks and environmental impacts.