What You Need to Know about Cement Bond Logging

Cement bond logging is used in the oil and gas industry to evaluate the integrity of the cement bond between the casing and the surrounding rock formation. This process is essential for ensuring that the cementing job performed during the well construction phase has been effective, providing proper zonal isolation and preventing fluid migration between different formation layers. Cement bond logging helps identify potential issues with well integrity that could lead to costly remediation efforts or, in the worst cases, well failure.

The Importance of Cement Bond Logging

Cementing plays a pivotal role in well integrity by ensuring that the wellbore is securely sealed. The cement creates a barrier that isolates various formations, preventing the migration of fluids and gases between different zones. Cement bond logging helps assess the effectiveness of this barrier by providing a real-time analysis of how well the cement has adhered to the casing and the formation.

Effective zonal isolation ensures that production zones are not contaminated with fluids from non-targeted zones. It also prevents the risk of wellbore leaks, which could lead to blowouts, groundwater contamination, and other safety hazards. Therefore, cement bond logging is a critical step in maintaining the long-term safety and productivity of a well.

How Cement Bond Logging Works

1. Basic Working Principles of Cement Bond Logging

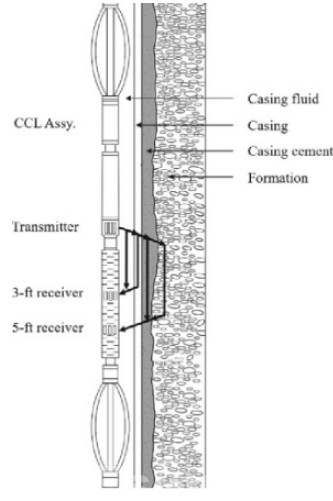

Cement bond logging works by sending acoustic signals down the wellbore and measuring how these signals interact with the casing, cement, and formation. The acoustic signals are generated by a tool, usually an acoustic or sonic tool, that is run into the well on a wireline or slickline.

The acoustic tool emits sound waves that travel through the casing and cement before reflecting off the surrounding formation. The quality of the cement bond is determined by how these waves are reflected. The key factor here is the speed and strength of the reflected signal. The basic idea is that well-bonded cement will reflect sound waves in a different way than poorly bonded or channelized cement.

2. Key Components of Cement Bond Logging

| Component | Function | Importance |

| Sonic Transmitter | Emits acoustic (sonic) waves into the casing and surrounding materials. | Initiates the signal required to measure acoustic travel time and amplitude. |

| Sonic Receivers | Detects the acoustic signals after they pass through the casing and cement. | Measures the waveforms to assess the bond quality between casing, cement, and formation. |

| Logging Tool Body | Houses all sensors and electronics for data acquisition. | Ensures structural integrity and protects components in high-pressure environments. |

| Telemetry System | Transmits data from downhole sensors to the surface logging unit. | Enables real-time monitoring and recording of cement bond logging data. |

| Centralizers | Keeps the tool centered in the wellbore during logging. | Ensures accurate and consistent measurements around the casing circumference. |

| Data Processing Software | Interprets raw signal data into usable log outputs (cement bond logging, VDL, etc.). | Provides visual and numerical analysis of cement bond integrity. |

| Power Supply Unit | Powers all sensors and transmitters in the tool. | Enables continuous tool operation throughout the logging run. |

3. Types of Acoustic Signals Used in Cement Bond Logging

There are two primary types of acoustic signals used in cement bond logging:

- Compressional Waves (P-Waves): These are the primary sound waves emitted by the tool. They travel faster through the cement and casing and are less affected by small irregularities in the formation. The compressional waves are typically used to assess the bond quality.

- Shear Waves (S-Waves): Shear waves are also used in more advanced forms of cement bond logging. They provide more detailed information about the bond quality because they interact differently with the casing, cement, and formation. These waves can identify more subtle variations in cement bond strength.

4. How the Data is Interpreted

- Echo Analysis: The acoustic tool measures the strength and timing of the reflected waves. A clear, distinct reflection indicates that the cement has bonded well to the casing and formation. On the other hand, a weak or delayed reflection suggests that the bond is incomplete or there are voids or channels in the cement.

- Time and Amplitude: The travel time of the acoustic waves is used to calculate the distance between the tool and the formation. The amplitude of the reflected waves indicates the strength of the bond. Stronger bonds create higher amplitude signals, while weak bonds lead to weaker signals.

- Graphical Presentation: The results are typically displayed in a graph, with the depth on the x-axis and the amplitude or travel time on the y-axis. The data is often represented in color or as a waveform, which allows engineers to visualize where the cement bond is strong or weak. A good bond will show clear, consistent signals, while a poor bond may display weak or erratic signals, indicating areas of concern.

5. Interpretation of Cement Bond Log Results

- Good Bond: If the cement is well-bonded to the casing and formation, the acoustic tool will produce strong and consistent signals. This suggests that the cement has effectively isolated the different zones in the wellbore and has created a secure seal between the casing and the formation.

- Poor Bond: Areas of weak or inconsistent reflections indicate poor bonding between the cement and the casing or formation. This can be due to several factors, such as incomplete cement placement, gas migration, or formation irregularities. In such cases, remediation, such as re-cementing or using additional tools, may be required to correct the issue.

- Cement Channeling: In some cases, the cement may fail to form a continuous seal, creating channels where fluids can migrate. This is typically visible as a lack of acoustic return in certain sections of the wellbore, indicating areas where the cement did not properly bond.

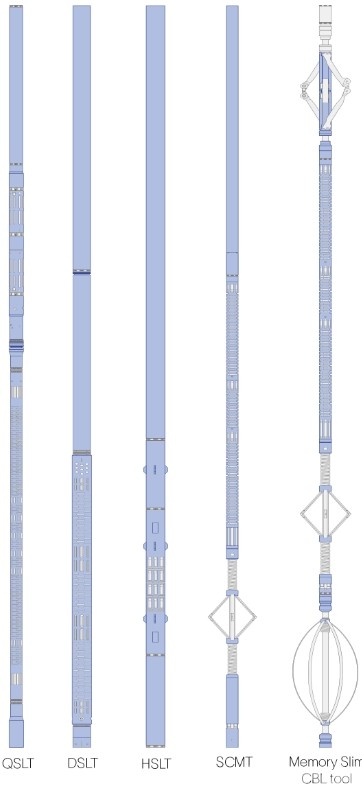

Types of Cement Bond Logging Techniques

| Technique | Description | Typical Applications |

| Conventional Cement Bond Log | Measures the amplitude of sonic waves through the casing and cement. | Basic evaluation of cement bonding quality, widely used for initial assessments. |

| Variable Density Log | Visualizes the full waveform of the sonic signal for more detailed analysis. | Detection of micro-annuli, gas channels, and improved visualization of bonding patterns. |

| Ultrasonic Imaging Tools | Uses high-frequency sound waves to provide a 360° image of the casing and cement. | Precise evaluation of cement thickness, casing damage, and channeling. |

| Radial Bond Log | Measures cement bond quality at multiple azimuthal points around the casing. | Identifying eccentric bonding issues and directional integrity evaluation. |

| Sonic Scanner Tools | Uses multiple sonic frequencies to enhance resolution and depth of investigation. | Advanced formation evaluation, casing evaluation, and complex well geometry analysis. |

| Cement Evaluation Tools | Combines sonic and ultrasonic measurements for comprehensive assessment. | Complex wells, deviated or horizontal wells, and high-resolution cement analysis. |

Applications of Cement Bond Logging

- Well Integrity Assessment

cement bond logging is primarily used to evaluate the integrity of the cement job. By identifying any voids, channels, or poor bonding between the cement and the casing, operators can assess whether the cement provides an effective seal. This ensures the well’s structural integrity, preventing issues such as fluid migration between different formations, which could lead to contamination or blowouts.

- Detection of Gas Migration

During drilling and cementing operations, gas migration can occur if the cement fails to form a proper seal. cement bond logging helps detect gas or fluid movement behind the casing, which can lead to dangerous conditions. By identifying gas migration early, operators can take corrective action to prevent issues such as blowouts or well control problems.

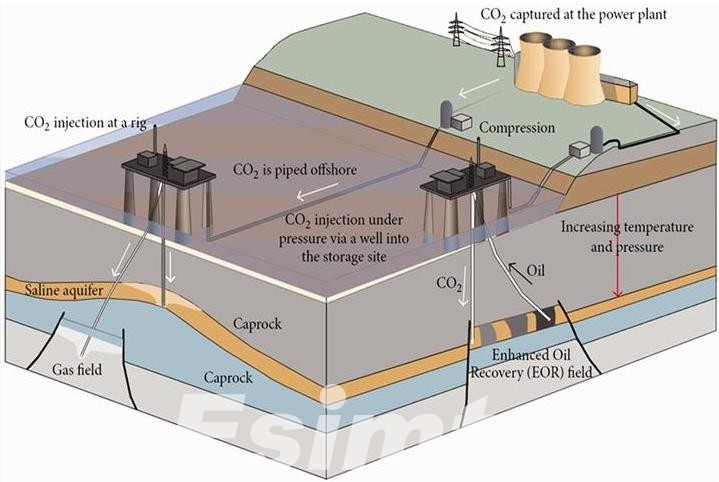

- Isolation of Reservoir Zones

Cement is used to isolate different reservoir zones, ensuring that production or injection takes place only in the intended zone. cement bond logging can verify that cement has successfully isolated these zones. If there is poor bonding or inadequate isolation, cement bond logging can highlight these areas, allowing for corrective actions to be taken before production begins.

- Assessment of Remediation Needs

In cases where initial cementing jobs have failed or are suspected to have failed, cement bond logging is used to assess whether remediation is required. It helps operators identify the locations and extent of poor cement bonding, guiding the decision on whether to perform remedial cementing operations to restore the well’s integrity.

- Wellbore Cleanup and Completion

Cement bond logging can be employed after wellbore cleanup to verify the cement’s condition and ensure that all necessary zones are isolated properly. It is crucial for confirming that all pre-production requirements have been met before the well is put into production.

- Wellbore Abandonment

In well abandonment operations, cement bond logging plays a key role in verifying that the well has been adequately sealed off to prevent future fluid migration. It is used to ensure that all zones are properly isolated and that the wellbore is securely plugged, thereby reducing environmental risks.

- Enhanced Well Logging and Monitoring

Cement bond logging is also used in combination with other well logging techniques (such as ultrasonic and acoustic logging) to provide a more comprehensive understanding of well conditions. This combined approach allows for a more accurate assessment of well conditions over time, helping to optimize production and improve safety.

- Predictive Maintenance and Risk Management

Using cement bond logging data in a long-term monitoring strategy can help predict when cement bond failure may occur. This information enables better planning of well maintenance and early intervention to prevent potential issues such as fluid contamination, compromised well integrity, or costly remedial work.

- Enhanced Reservoir Management

Cement Bond Logging plays a critical role in optimizing reservoir management by ensuring that the cement job is properly executed and that the integrity of multiple reservoir zones is maintained. Accurate information on cement bonding quality allows for better reservoir zoning and isolation during production and injection activities.

- Production Optimization

In enhanced oil recovery operations, cement bond logging can help ensure that injected fluids (such as water or gas) are properly confined to the intended reservoir zones. It can also identify areas of leakage or failure, allowing for better optimization of recovery techniques by ensuring that injected fluids do not escape into unintended zones.

Challenges and Solutions in Cement Bond Logging

Like any other downhole measurement technique, it comes with its own set of challenges. These challenges can arise from various well conditions, tool limitations, or operational factors. Understanding these challenges and the corresponding solutions is essential for effective use of cement bond logging technology, enhancing the accuracy, reliability, and interpretability of cement bond logging results in increasingly complex well environments.

| Challenge | Description | Solution |

| Poor Centralization of Tool | Off-center tools cause inaccurate measurements and uneven cement evaluation. | Use of centralizers and real-time position monitoring to ensure proper tool alignment. |

| Presence of Micro-Annuli | Small gaps between casing and cement can go undetected in conventional cement bond logging. | Use high-resolution tools like Ultrasonic Imaging or Radial Bond Logs for detailed detection. |

| Gas Channeling in Cement | Gas pockets can distort acoustic signals, mimicking poor cement bonding. | Apply advanced signal processing and run gas detection logs to differentiate true bonding. |

| Deviated or Horizontal Wells | Gravity affects cement placement and tool orientation in non-vertical wells. | Deploy flexible logging tools designed for deviated wells with enhanced orientation control. |

| High-Temperature/High-Pressure Well Conditions | Extreme conditions can impact tool performance and data reliability. | Use temperature and pressure-rated tools built for harsh environments. |

| Complex Well Geometries | Multi-lateral or irregular wells complicate signal interpretation. | Employ 3D modeling and simulation tools to interpret results more accurately. |

| Low Acoustic Contrast | Similar acoustic properties of casing and cement reduce signal clarity. | Use multi-frequency or ultrasonic tools to enhance contrast and measurement accuracy. |

| Tool Noise or Signal Interference | Electrical or mechanical noise can contaminate signal data. | Implement improved shielding and filtering techniques in data acquisition systems. |

How Simulation Technologies are Used for Optimizing Cement Bond Logging

Oil and gas simulation technologies can optimize cement bond logging by providing deeper insights into the quality and effectiveness of the cement job. These tools enable accurate predictions, more informed decision-making and enhanced remediation strategies in well completions.

| Simulation Technology | Purpose | Benefit in Cement Bond Logging |

| Finite Element Analysis (FEA) | Simulates the behavior of the cement bond under various stress conditions. | Helps predict potential failure zones, such as voids or poor bonding, allowing targeted remediation. |

| Flow Simulation Software | Models fluid flow through the wellbore and cement annulus. | Optimizes cement placement and identifies areas with potential incomplete cementation. |

| Acoustic Modeling | Simulates the acoustic wave propagation in the cement sheath. | Enhances the accuracy of cement bond evaluation by refining the interpretation of sonic log data. |

| Wellbore Pressure Simulation | Models pressure variations in the wellbore during cementing operations. | Assists in predicting pressure-related issues and ensuring proper cementing integrity. |

| 3D Visualization Software | Provides a three-dimensional view of well construction and cement bond data. | Improves the understanding of cement placement and helps identify regions of poor bonding. |

| Inversion Modeling | Inverts field data to create models of cement bond quality. | Refines interpretations of bond quality from logging data, enhancing the decision-making process. |

| Machine Learning Algorithms | Analyzes past logging data and operational conditions to predict cement bond quality. | Helps identify trends and anomalies, improving the prediction of cement bonding failures or successes. |

Final Thoughts

Cement bond logging is a critical part of ensuring the integrity and safety of oil and gas wells. It provides valuable information about the quality of the cement job, helps verify zonal isolation, and is vital in production optimization and well maintenance. Despite the challenges, advances in technology and improved logging methods continue to make cement bond logging a reliable and essential tool for the industry.