What is Trenchless Drilling in Oil and Gas Exploration

In the oil and gas industry, advances in various technologies continue to push the boundaries of exploration and production. Among them, trenchless drilling provides a less invasive and more efficient way to access underground resources. Unlike traditional drilling methods that require extensive excavation, trenchless technology is a cleaner, faster and more environmentally friendly alternative.

Trenchless Drilling Overview

Trenchless drilling refers to a set of advanced techniques used to install underground infrastructure or access subsurface resources without the need for large-scale excavation. Unlike traditional methods, which require digging extensive trenches to lay pipes or extract materials, trenchless drilling involves minimal surface disturbance. This makes it ideal for use in urban environments, ecologically sensitive areas, and locations with existing infrastructure, where large-scale disruption would be costly or impractical.

The key advantage of trenchless drilling lies in its ability to install pipelines, conduits, or access oil and gas reservoirs without significant environmental or community impact. The technology allows operators to navigate around natural and man-made obstacles like rivers, highways, and buildings. It is highly precise and can be adapted to varying geological conditions, offering flexibility in directional control and depth. Additionally, trenchless methods typically require less labor, equipment, and time, resulting in cost savings while improving operational efficiency.

Types of Trenchless Technologies

Trenchless drilling encompasses a range of advanced techniques designed to install and maintain pipelines and underground infrastructure without significant surface disturbance. These methods are especially valuable in oil and gas exploration, where environmental preservation and minimal surface disruption are critical. The following are the key trenchless technologies, each with specific applications and advantages:

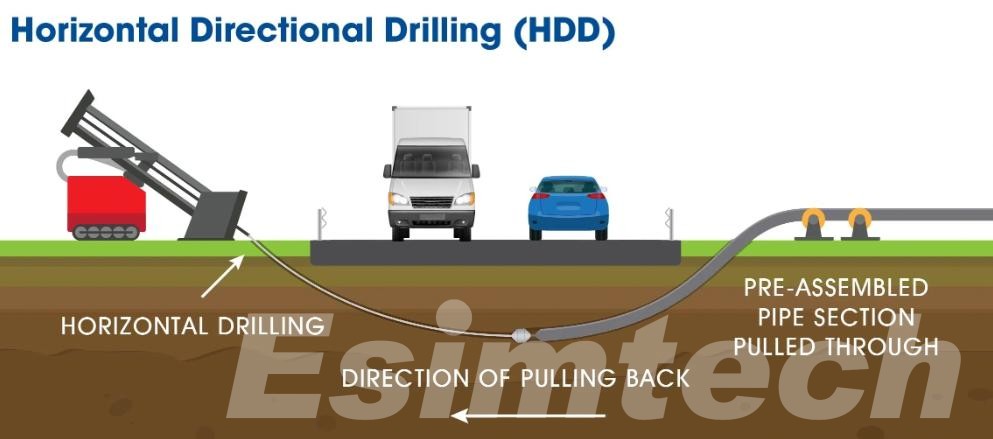

Horizontal Directional Drilling

Horizontal Directional Drilling (HDD) is a widely adopted trenchless technology, especially in the oil and gas sector. It is well-suited for installing pipelines beneath obstacles like rivers, roads, or densely populated areas, where conventional open-cut methods are either unfeasible or too expensive.

How HDD Works:

- Pilot Bore: The process begins by drilling a pilot hole using a steerable drill bit, which follows a pre-planned path designed to bypass surface obstacles.

- Tracking and Steering: Throughout drilling, sophisticated tracking systems are used to monitor the drill’s depth and position, ensuring it stays on course, particularly when passing under water bodies or urban structures.

- Reaming: After the pilot hole is completed, it is expanded to the required diameter through reaming, which may occur in multiple stages depending on the size of the pipeline.

- Pipeline Installation: Finally, the pipeline or casing is pulled back through the enlarged borehole, completing the installation. HDD can be applied over long distances, sometimes spanning several kilometers.

HDD is highly versatile and can be applied in various ground conditions, including soft soils and hard rock. It also allows for precise control of the drilling path, making it ideal for complex crossings, such as under rivers, highways, or urban areas.

Microtunneling

Microtunneling is a trenchless method used to install pipelines with a high degree of accuracy, often in locations where space is limited, or surface disruption needs to be minimized. It is particularly suitable for large-diameter pipes and works well in both soft ground and areas with groundwater.

How Microtunneling Works:

- Microtunneling involves the use of a remotely controlled microtunnel boring machine (MTBM), which is launched from a small entry pit. The MTBM digs through the ground while pipes are simultaneously pushed into place behind it.

- The process is monitored from the surface, and guidance systems ensure that the tunnel is driven accurately along the designed path, making it highly precise even in difficult soil conditions.

- The excavated material is transported back to the surface through a slurry pipeline, which uses water or drilling fluid to remove the spoil from the face of the tunnel.

Microtunneling is ideal for urban environments or places where minimal disruption is required. It allows for greater precision and is highly effective in saturated soils or areas with high groundwater pressure. It is also more efficient for larger-diameter pipelines compared to other trenchless methods.

Auger Boring

Auger boring is a trenchless method primarily employed for the installation of pipelines beneath roads, railways, and other surface obstacles when longer or more complex routes are unnecessary. This technique is particularly effective for small to medium-diameter pipelines in straightforward projects.

How Auger Boring Works

- The process begins with the excavation of a launch pit, where the auger boring machine is positioned. A cutting head at the front of the auger drill is driven into the ground to remove soil.

- As the machine advances, an auger screw within the pipe rotates, transporting the excavated material back to the launch pit. This method is particularly suited for installing steel casings, which can later house additional pipes.

- The cutting head can be adjusted for various soil types, ensuring accurate boring across different terrains.

Auger boring is a straightforward and cost-effective solution, especially for pipeline installations under roads or railways over short distances. It is a well-established technology that can be completed relatively quickly when compared to other methods.

Pipe Jacking

Pipe jacking is a trenchless construction method that utilizes hydraulic pressure to push prefabricated pipes into position while excavating the surrounding material from the front of the advancing pipeline. This technique is especially effective for installing large-diameter pipelines over short distances, making it ideal for crossing beneath roads, highways, and other obstacles.

How Pipe Jacking Works:

- In a pipe jacking operation, prefabricated pipe sections are loaded into a launch pit and propelled into place using powerful hydraulic jacks.

- At the leading edge of the pipe string, an excavation tool—sometimes a Micro Tunnel Boring Machine (MTBM)—is employed to dig through the soil as the pipe moves forward. The excavated material is then removed from the tunnel, often using a conveyor belt or other mechanical systems.

- This process continues until the entire pipeline length is successfully installed.

Pipe jacking is particularly advantageous for large-diameter pipelines and projects requiring straight-line installations over short distances. It is commonly used for water and sewer systems, as well as in oil and gas applications where precise alignment is essential.

The Role of Trenchless Drilling in Oil and Gas Exploration

As energy companies increasingly focus on minimizing their environmental footprint while maintaining operational efficiency, trenchless technologies provide the means to extract and transport oil and gas with minimal surface disruption. This has made trenchless drilling indispensable for navigating difficult terrains, protecting sensitive ecosystems, and enabling resource extraction in challenging locations.

How Trenchless Drilling Works

Trenchless drilling follows a multi-step process, combining precision technology and careful planning to minimize surface impact. Here’s how it works:

- Pilot Hole Creation: The process begins by drilling a small-diameter pilot hole along a carefully planned route. Advanced directional control systems ensure that the drill follows the desired path, even under obstacles like rivers, highways, or densely populated areas.

- Borehole Expansion: Once the pilot hole is completed, it is enlarged to the required diameter using a reaming tool. This step prepares the hole for the installation of the pipeline or casing, ensuring sufficient space for the final infrastructure.

- Pipeline Installation: After the borehole is widened, the pipeline or utility is pulled into place. The pipe is guided through the underground path with minimal stress, reducing the risk of damage during installation.

- Restoration: Once the pipeline is in place, surface restoration is completed at entry and exit points, leaving the environment largely undisturbed. The minimal surface impact is one of the most significant advantages of trenchless drilling.

This process enables oil and gas companies to safely and efficiently install pipelines across complex terrains while avoiding significant surface disturbances.

Application of Trenchless Drilling in Oil and Gas

Trenchless drilling has become a key technology in the oil and gas industry due to its versatility and minimal environmental impact. It is widely used in various applications, ensuring that companies can install, maintain, and repair pipelines and other infrastructure efficiently and with reduced surface disruption. Here are the main ways trenchless drilling is applied in oil and gas operations:

- Pipeline Installation: One of the primary uses of trenchless drilling is in the installation of pipelines that transport oil and gas over long distances. This method is particularly valuable for crossing challenging geographical features like rivers, mountains, or densely populated urban areas. Horizontal Directional Drilling (HDD), for instance, enables pipelines to be installed beneath obstacles without disturbing the surface, which reduces the environmental footprint and ensures the safety and reliability of pipeline operations.

- Well Drilling: Trenchless techniques are essential in the drilling of wells, especially when targeting unconventional resources like shale oil and gas. Horizontal drilling allows operators to reach a broader area of the reservoir from a single entry point, significantly increasing the amount of hydrocarbons extracted while minimizing the surface impact. This method has been instrumental in the development of shale plays and other unconventional resources.

- Pipeline Maintenance and Repairs: Trenchless drilling is also used for the maintenance and repair of existing pipelines without requiring full excavation. Techniques such as pipe relining or directional drilling can be employed to fix leaks or reinforce aging infrastructure while keeping disruption to a minimum. This is critical for ensuring continuous operation and reducing the costs associated with downtime.

- Crossing Infrastructure and Urban Areas: Trenchless drilling is invaluable when pipelines need to cross under existing infrastructure such as highways, railroads, or urban areas. Rather than disrupting traffic or causing significant inconvenience to local communities, trenchless methods enable pipelines to be installed underground without surface-level disruption. This ensures projects can be completed faster and more cost-effectively, avoiding the need for extensive road closures or construction in populated areas.

In summary, trenchless drilling enhances the ability of oil and gas companies to safely and efficiently install, maintain, and repair infrastructure in a wide range of environments, from rural landscapes to densely populated urban settings. It provides a solution that balances operational needs with environmental considerations, making it a critical technology in the industry.

The Future of Trenchless Drilling?

Trenchless drilling has transformed oil and gas exploration by enabling efficient installation and maintenance of pipelines with minimal environmental impact. Technologies like Horizontal Directional Drilling and micro tunneling allow companies to navigate challenging terrains and urban settings safely. As the industry adapts to growing energy demands, trenchless methods will be vital for sustainable and responsible resource extraction.