What is Subsea Production System in Oil and Gas

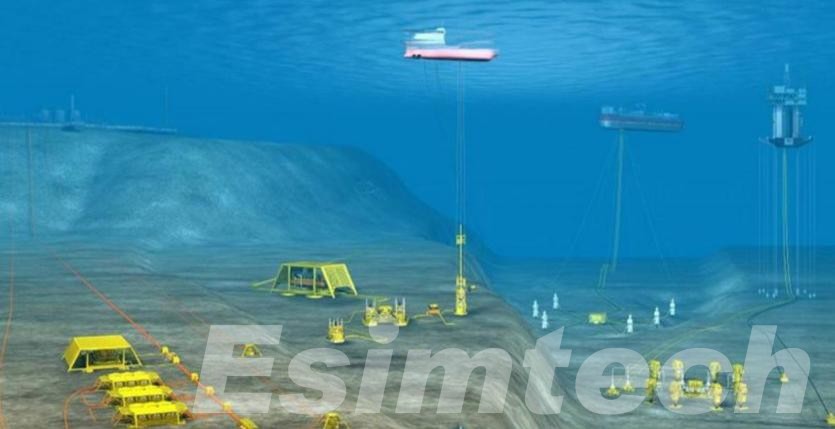

A subsea production system is an underwater technology in the oil and gas industry for extracting hydrocarbons from beneath the seafloor. Essential in offshore operations, it operates in deep waters and withstands harsh underwater conditions, moving oil and gas from the seabed to surface facilities or onshore processing units. This technology has revolutionized offshore production, enabling access to resources in previously unreachable areas, extending field life, and supporting deepwater operations.

Define Subsea Production System

A subsea production system is a sophisticated underwater infrastructure used in offshore oil and gas extraction, where hydrocarbons are accessed from beneath the ocean floor. These systems serve as a bridge between the reservoir and the surface facilities, enabling the controlled production of oil and gas from deepwater and ultra-deepwater locations.

The subsea production system is typically anchored at the wellhead, where it interfaces with the reservoir. From there, a network of pipelines, valves, and control units manages the flow of hydrocarbons from the well to the surface, often across vast distances. Due to the remote and challenging conditions underwater, subsea production systems are engineered to operate autonomously and are monitored and controlled from remote facilities. Innovations in subsea technology have expanded the reach of offshore production, enabling access to energy reserves in locations once considered unreachable.

Key Components of Subsea Production System

A subsea production system is made up of various critical components. These components are specially designed to withstand extreme underwater conditions, including high pressures, low temperatures, and corrosive environments. Below is an overview of the main components that make up a subsea production system:

- Subsea Wellhead

The subsea wellhead is the foundational piece of the entire subsea production setup, positioned at the seafloor where it connects the wellbore to the production system. It provides structural support and pressure containment, anchoring the well to the seabed and serving as the starting point for the subsea system. The wellhead’s integrity is crucial, as it must withstand both the physical stresses of drilling and the high pressures from the reservoir below.

- Subsea Christmas Tree

The Christmas tree is a crucial assembly of valves, chokes, and gauges situated on top of the wellhead. It controls the flow of hydrocarbons, allowing operators to manage production rates and pressure levels efficiently. The subsea Christmas tree is engineered to withstand harsh underwater environments, including high pressures and corrosive conditions. Its components are often equipped with hydraulic or electrical actuators that enable remote operation, allowing for real-time adjustments and monitoring from surface facilities.

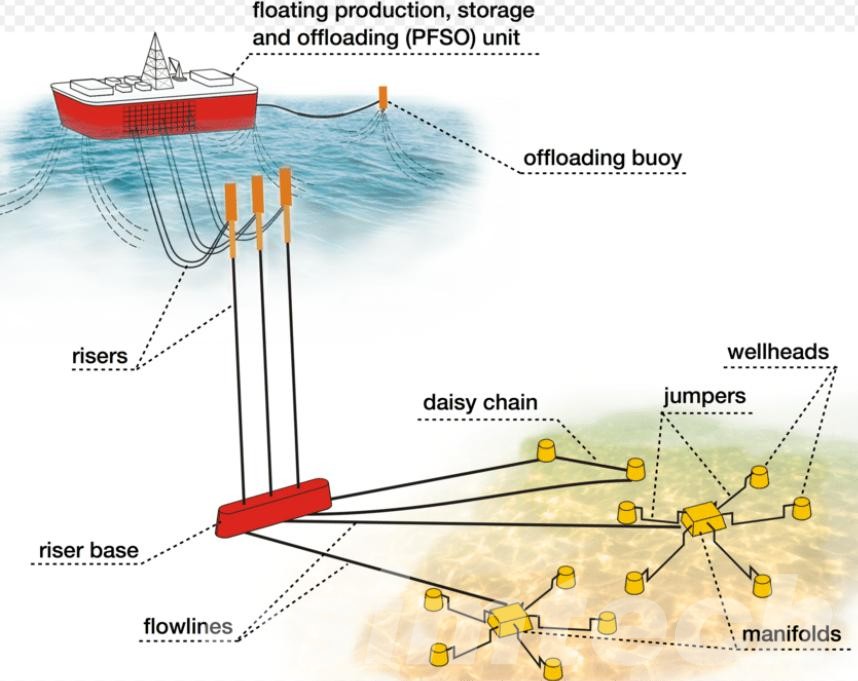

- Manifolds and Flowlines:

Subsea manifolds play a vital role in managing the flow of hydrocarbons collected from multiple wells. These complex assemblies are equipped with valves and piping systems that allow for the distribution of oil and gas to various flowlines. Flowlines are the underwater pipelines that transport produced hydrocarbons from the wellheads or manifolds to the risers or directly to surface facilities. Both manifolds and flowlines must be designed to handle high pressures and varying temperatures, ensuring a continuous and safe flow of production.

- Umbilicals

Umbilicals are composite cables that carry power, control signals, and injection chemicals necessary for the operation of subsea equipment. They connect surface facilities, such as platforms or floating production storage and offloading (FPSO) units, to the subsea components, allowing remote monitoring and control of the system. Umbilicals are typically made of several insulated steel and polymer sheaths, protecting the electrical and hydraulic lines within from environmental wear and tear.

- Subsea Control System

The subsea control system is integral to the safe and efficient operation of subsea production systems. It allows for remote monitoring and control of the various subsea components, enabling operators to manage production activities from a surface control room or an onshore facility. This system includes a network of sensors, valves, and communication devices that provide real-time data on pressure, temperature, and flow rates. The ability to operate subsea systems remotely enhances safety by minimizing personnel exposure to hazardous underwater environments.

- Risers

Risers are vertical pipes that connect the subsea system to surface facilities, such as production platforms or floating production storage and offloading (FPSO) units. They transport hydrocarbons, as well as injection fluids, between the seafloor and the surface. Risers must be engineered to withstand dynamic forces from ocean currents, pressure changes, and thermal expansion, making their design and construction complex. Various types of risers exist, including flexible risers, rigid risers, and hybrid systems, each chosen based on specific operational needs and environmental conditions.

These key components work in tandem to create an efficient subsea production system, ensuring the safe and effective extraction of oil and gas from beneath the ocean floor.

Types of Subsea Production Systems

Subsea production systems come in several forms, each tailored to meet the demands of specific field characteristics, water depths, and economic factors. Here are four of the most important types of subsea production systems:

Subsea Tieback Systems

A subsea tieback system connects new wells to existing infrastructure, enabling the expansion of production in nearby areas without the need to build new surface facilities. In this setup, flowlines and umbilicals link new wells directly to a nearby existing platform or floating production facility. This method is often used when a small reservoir is located close to an established production site, making it economically viable by minimizing capital expenditure.

- Cost Efficiency: With fewer new installations needed, subsea tiebacks reduce both capital and operational costs.

- Quicker Development: By leveraging existing infrastructure, tiebacks significantly shorten project timelines, making it easier to bring additional reserves online.

- Field Life Extension: By connecting additional wells to an existing facility, tiebacks can extend the life of mature fields, boosting overall production without requiring new platforms or FPSOs.

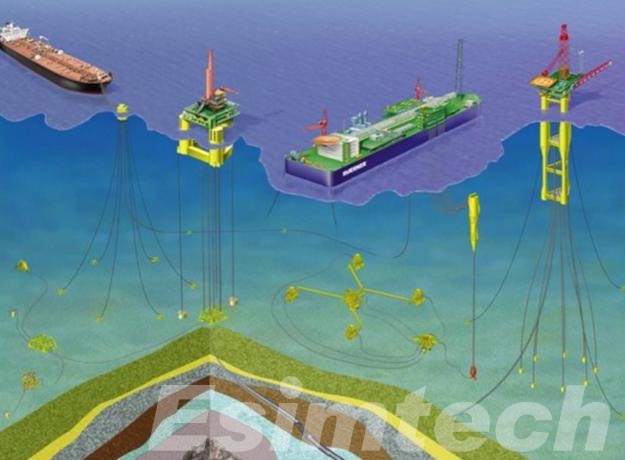

Standalone Subsea Production Systems

Standalone systems are used for larger reservoirs located farther from existing infrastructure. They comprise a complete set of subsea equipment, including wellheads, risers, manifolds, and control systems, which send hydrocarbons to floating production, storage, and offloading (FPSO) units or surface platforms. Standalone systems are often chosen when the reservoir size and production volume justify the cost of a dedicated setup.

- Autonomous Operation: These systems are designed to operate independently, making them ideal for remote and deepwater locations where tiebacks are impractical.

- Higher Production Volumes: Standalone systems can accommodate more wells and handle larger volumes, making them suitable for larger fields with longer production lifespans.

- Advanced Control Systems: These systems often feature sophisticated automation and monitoring technologies that allow for efficient production control and reduced operational risks in deepwater environments.

Hybrid Subsea Systems

Hybrid subsea production systems combine elements of both subsea tiebacks and standalone systems, providing a flexible and adaptable approach to offshore production. They are designed to optimize the extraction of hydrocarbons from multiple wells and can utilize various surface facilities.

- Flexible Configurations: Hybrid systems can connect multiple subsea wells to a single manifold, which can then route the production to either nearby surface platforms or FPSOs. This flexibility allows operators to adapt to changing field conditions and production needs effectively.

- Cost-Effective Scaling: As new discoveries are made, additional subsea wells can be easily integrated into the existing hybrid system without the need for significant additional infrastructure, making it a cost-effective solution for expanding production.

- Enhanced Recovery: By leveraging various production methods, including tiebacks to existing platforms and standalone capabilities, hybrid systems can improve recovery rates from the field. This integrated approach helps optimize reservoir management and maximize resource extraction.

Deepwater and Ultra-Deepwater Systems

Deepwater and ultra-deepwater subsea production systems are specifically engineered for operation at significant depths, typically greater than 1,500 meters (about 4,920 feet). These systems are designed to withstand extreme pressures and temperatures, making them suitable for the most challenging offshore environments.

- Advanced Technology: Deepwater systems incorporate cutting-edge technologies, such as high-pressure, high-temperature (HPHT) equipment, to handle the unique challenges posed by deepwater conditions. This includes robust materials that resist corrosion and structural failure due to high underwater pressures.

- Subsea Processing: To optimize production from deepwater fields, many systems include subsea processing units that can perform separation and compression tasks underwater. This reduces the volume of fluids transported to the surface, minimizing transportation challenges and costs.

- Remote Monitoring and Control: Due to their depth and distance from the shore, deepwater systems rely heavily on sophisticated remote monitoring and control systems. These systems provide real-time data on production performance, equipment status, and reservoir conditions, enabling operators to make informed decisions and respond quickly to any issues that may arise.

Subsea production systems, including tiebacks, standalone setups, and deepwater solutions, showcase the adaptability of offshore oil and gas technology. Each system is tailored to specific conditions, enabling efficient resource extraction in challenging underwater environments. Ongoing technological advances are set to further boost the effectiveness of these systems, expanding offshore energy potential.

Advantages of Subsea Production System

Subsea production systems provide numerous benefits that make them an attractive choice for offshore oil and gas operations, particularly in challenging deepwater and ultra-deepwater environments. Key advantages include:

a. Access to Remote Reserves:

Subsea systems enable the extraction of hydrocarbons from locations that would otherwise be deemed inaccessible or uneconomical. This capability allows operators to tap into valuable reserves found in deep waters and remote regions.

b. Reduced Environmental Impact:

By situating production equipment on the seabed and minimizing the need for large surface platforms, subsea systems significantly lower the environmental footprint of offshore operations. This design helps mitigate the risk of oil spills and minimizes disturbances to marine ecosystems.

c. Enhanced Safety:

The remote operation of subsea production systems reduces the need for personnel to work in hazardous environments, thus improving safety for workers. The automated nature of these systems allows for efficient monitoring and control while minimizing risks associated with offshore operations.

d. Increased Operational Efficiency:

With advanced automation and control technologies, subsea production systems enhance operational efficiency. They streamline processes, reduce maintenance needs, and improve hydrocarbon recovery rates, ultimately contributing to better overall field economics.

e. Scalability and Flexibility:

Subsea production systems are highly adaptable and can be easily scaled to meet changing field requirements. Additional wells can be tied back to existing subsea infrastructure, allowing operators to expand production capabilities without the need for extensive new construction.

Generally, subsea production systems combine technological innovation with environmental stewardship, safety, and operational efficiency, making them a crucial component of modern offshore oil and gas exploration and production.

In summary, subsea production systems play a vital role in modern offshore oil and gas extraction. Their advanced technology enhances safety, efficiency, and access to remote reserves while minimizing environmental impact. As the industry evolves, these systems will continue to be crucial for unlocking the potential of deepwater resources.