What is Rigless Well Intervention

Rigless well intervention technologies have transformed the oil and gas industry by providing cost-effective and efficient alternatives to traditional drilling rigs for maintaining and enhancing well performance. These methods allow operators to perform repairs, stimulation, and production optimization without the need for a costly workover rig, reducing downtime and operational expenses. With advances in wireline, coiled tubing, and hydraulic workover technologies, ringless well interventions have become a crucial part of modern well management strategies.

Key Technologies in Rigless Well Intervention

1. Coiled Tubing

One of the most widely used rigless well intervention technologies is coiled tubing, a continuous steel pipe wound on a spool and deployed into wells for various operations. This technology enables wellbore cleanouts, acid stimulation, nitrogen lifting, and logging activities without requiring a conventional workover rig. The real-time data monitoring capability of coiled tubing ensures better control over intervention processes, improving overall well performance. Additionally, coiled tubing operations are quicker and more cost-effective, making them a preferred choice for well maintenance.

2. Wireline and Slickline

Wireline and slickline technologies play a crucial role in rigless well interventions by providing precise and efficient well diagnostics, perforation, and downhole tool manipulation. Wireline operations utilize an electric cable to transmit real-time data, allowing operators to assess well conditions and make informed decisions. Slickline, on the other hand, is a mechanical cable system used to retrieve and deploy downhole tools. Both methods require minimal surface infrastructure, making them ideal for quick interventions without disrupting production. Their reliability and accuracy contribute significantly to optimizing well performance.

3. Hydraulic Workover Units

Hydraulic workover units offer an alternative to traditional rigs for heavy-duty well interventions. These units use hydraulic force to insert and extract tubing, providing enhanced control over high-pressure wells. Hydraulic workover units are particularly effective in well completions, plug and abandonment (P&A) operations, and tubular replacements. Their mobility and adaptability make them suitable for offshore and remote locations where rig-based interventions are impractical. By eliminating the need for large-scale rig mobilization, hydraulic workover units reduce costs and improve operational efficiency.

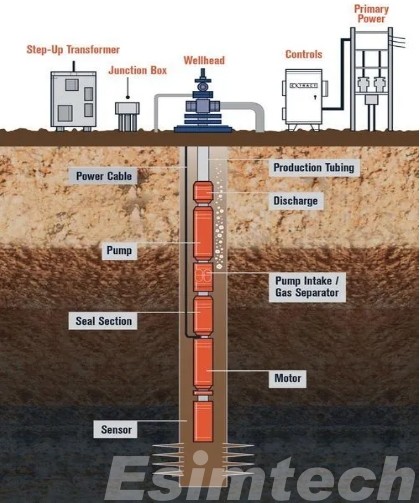

4. Electric Submersible Pump Interventions

Maintaining and replacing electric submersible pumps without shutting down production has become possible with rigless eelectric submersible pump interventions. These techniques, including cable-deployed electric submersible pumps and modular rigless electric submersible pump replacement systems, significantly reduce downtime and ensure continuous well operation. The ability to replace pumps without pulling the tubing enhances production efficiency while lowering operational costs. As artificial lift systems continue to evolve, electric submersible pump interventions are becoming increasingly valuable for optimizing well performance in mature fields.

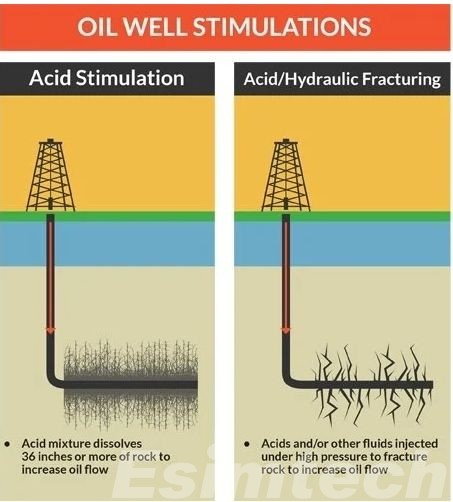

5. Well Stimulation Techniques

Well stimulation technologies, such as hydraulic fracturing, acidizing, and chemical injection, play a vital role in improving reservoir performance without requiring a rig. Hydraulic fracturing enhances permeability by creating fractures in the rock formation, allowing hydrocarbons to flow more freely. Acidizing dissolves formation blockages, increasing production rates. Additionally, advanced chemical treatments using nanotechnology are being developed to further optimize reservoir performance. These rigless stimulation methods are essential for revitalizing declining wells and maximizing recovery.

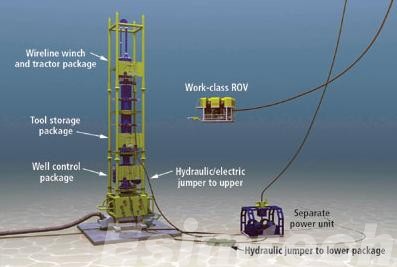

6. Robotics and Remote-controlled Systems

Robotics and remote-controlled systems are transforming rigless well intervention by enhancing efficiency, safety, and precision. Autonomous downhole robots are capable of performing inspections, minor repairs, and data collection without human intervention. Remotely operated vehicles (ROVs) and drones are used for offshore well monitoring, reducing the need for personnel exposure to hazardous environments. Additionally, AI-driven control systems enable real-time diagnostics and predictive maintenance, optimizing intervention strategies. These advancements minimize downtime, lower operational costs, and improve well integrity, making them a critical component of modern oil and gas operations.

Applications of Rigless Well Intervention

| Application | Description | Key Technologies Used |

| Wellbore Cleanout | Removal of sand, scale, and debris to restore well flow. | Coiled Tubing, Slickline |

| Well Logging & Diagnostics | Assessing well conditions and reservoir performance. | Wireline, Coiled Tubing |

| Perforation | Creating pathways for hydrocarbons to flow into the wellbore. | Wireline, Slickline |

| Acid Stimulation | Injecting acid to dissolve formation blockages and improve permeability. | Coiled Tubing, Pumping Units |

| Nitrogen Lifting | Injecting nitrogen to remove liquid buildup and enhance production. | Coiled Tubing, Gas Lift |

| Hydraulic Fracturing | Enhancing reservoir permeability by creating fractures. | Pumping Units, Coiled Tubing |

| Tubing & Equipment Replacement | Removing or replacing damaged tubing or downhole tools. | Hydraulic Workover Units, Wireline |

| Artificial Lift Optimization | Maintaining or replacing Electric Submersible Pumps (ESPs) without a rig. | Rigless ESP Deployment Systems |

| Plug & Abandonment (P&A) | Sealing depleted wells permanently for environmental safety. | Hydraulic Workover Units, Wireline |

| Leak Detection & Remediation | Identifying and fixing leaks in casing, tubing, or packers. | Wireline, Coiled Tubing |

| Production Enhancement | Enhancing well productivity through chemical or gas injection. | Coiled Tubing, Pumping Systems |

Challenges and Future Trends in Rigless Well Intervention

This chart highlights both the challenges faced and the emerging trends aiming to overcome them.

| Challenges | Description | Future Trends |

| Limited Equipment Availability | Lack of specialized equipment for certain well conditions and interventions. | Robotics and automated systems will be developed to perform more precise and efficient interventions. |

| Well Integrity and Safety Concerns | Ensuring the well is safe for intervention without risking blowouts or leaks. | Real-time data from well sensors will enhance decision-making and safety during operations. |

| Limited Well Access and Harsh Environments | Rigless interventions are challenging in remote or harsh weather environments. | AI will be used to predict well failures and optimize intervention timing, reducing downtime. |

| Complexity in Well Diagnostics | Diagnosing well issues without a rig can be difficult and may require innovative techniques. | Drones will be used to monitor well sites, providing real-time footage and diagnostics without physical presence. |

| High Operational Costs | The cost of rigless interventions can be high due to specialized equipment and expertise. | Development of modular systems that can be easily customized for different well types, reducing costs. |

| Time Constraints in Performing Interventions | Limited time to intervene, especially in emergency situations or when the well is declining. | New materials with superior corrosion resistance will reduce wear and tear on equipment, extending lifespan and reducing costs. |

| Lack of Well-Specific Solutions | A one-size-fits-all approach doesn’t always work for complex or diverse well conditions. | Automated systems will handle logging and monitoring, making interventions faster and more accurate. |

| Environmental Regulations and Sustainability | Rigless interventions must comply with environmental regulations, which can be restrictive. | Digital twin technology will create virtual models of wells, allowing for better planning and forecasting of interventions. |

Key Applications of Simulation Technologies in Optimizing Rigless Well Intervention

- Wellbore Modeling and Performance Prediction

A fundamental application of simulation technologies in rigless well intervention is wellbore modeling and performance prediction. These digital models create a virtual representation of the well to analyze key factors such as wellbore stability, fluid flow dynamics, and pressure fluctuations. Engineers use these simulations to test different intervention strategies before execution, ensuring that tools and techniques are optimized for specific well conditions. This predictive approach helps prevent wellbore failures, tool sticking, and unexpected pressure surges, leading to safer and more efficient interventions.

- Real-Time Monitoring and Decision Support

Simulation technologies are increasingly integrated with real-time data acquisition systems, allowing operators to monitor well conditions and make informed decisions during interventions. These well intervention simulation systems continuously analyze well pressure, temperature, and flow rates, providing dynamic adjustments as conditions change. Artificial intelligence (AI) and machine learning algorithms further enhance this process by detecting trends, identifying risks, and suggesting optimal operational changes. This real-time decision support enables intervention teams to respond quickly to unexpected challenges, reducing downtime and improving well performance.

- Coiled Tubing and Fluid Dynamics Simulations

Coiled tubing is widely used in rigless well interventions for applications such as well cleaning, acid stimulation, and nitrogen lifting. Coiled tubing simulation technologies can model fluid injection rates, pressure behavior, and chemical interactions within the wellbore. This ensures that cleaning and stimulation treatments are effectively distributed, enhancing well productivity while minimizing the risk of formation damage. Additionally, flow assurance simulations help predict sand accumulation, debris movement, and hydrate formation, allowing operators to implement preventive measures before executing an intervention.

- Wireline and Downhole Tool Performance Analysis

Wireline interventions rely on deploying logging and mechanical tools to assess well conditions, set plugs, and perform perforation operations. Simulation technologies assist in selecting the right tools, predicting their performance, and analyzing potential hazards such as tool sticking or mechanical failures. Engineers can simulate different logging scenarios to ensure the accuracy of downhole measurements and optimize perforation designs for maximum reservoir connectivity and production enhancement. This helps reduce operational delays and minimizes the risk of tool retrieval issues.

- Hydraulic Workover and Snubbing Simulations

Hydraulic workover and snubbing operations involve working on live wells under pressure, making precision and safety critical. Simulation technologies allow engineers to assess tubular movement, snubbing unit performance, and well control strategies under high-pressure conditions. These models help predict how snubbing operations will affect well integrity and allow for preemptive adjustments to pressure control mechanisms. By simulating different snubbing scenarios, operators can enhance the efficiency of hydraulic workover operations while maintaining well safety and stability.

- Training and Operational Planning

One of the most valuable applications of simulation technologies is in training and workforce development. Virtual reality (VR) and interactive digital simulations allow intervention teams to practice complex well intervention procedures in a risk-free virtual environment. Operators can gain hands-on experience in handling wireline, coiled tubing, and snubbing equipment without exposing personnel or assets to actual operational risks. These training simulations improve team coordination, enhance procedural compliance, and reduce the likelihood of human errors during real-world interventions.

Final Thoughts

Rigless well intervention technologies have become essential for optimizing well productivity while minimizing costs and operational risks. Through providing predictive wellbore modeling, real-time monitoring, and operational optimization, simulation technologies have become indispensable in optimizing rigless well interventions. They can enhance efficiency, improving safety and reduce the costs associated with well interventions. With continuous advancements in automation, digitalization, and AI-driven solutions, the future of rigless interventions promises even greater precision, reliability, and sustainability.