What is Offshore Oil Well Intervention

Offshore oil well intervention refers to the process of accessing and modifying an underwater oil well to maintain its production or address operational issues. This involves various tasks, from routine maintenance to emergency repairs, all aimed at ensuring the safe and efficient extraction of oil and gas from the ocean floor.

Why Intervene in an Offshore Oil Well?

- Intervening in an offshore oil well is crucial for maintaining its productivity, safety, and longevity. Over time, well performance can decline due to natural reservoir depletion, mechanical issues, or blockages caused by sand, scale, or wax buildup. Without timely intervention, these problems can significantly reduce oil and gas production, leading to lower profitability.

- Intervention helps resolve issues such as pressure drops, damaged equipment, or wellbore obstructions that prevent optimal flow. It also provides opportunities to enhance production, for instance, by stimulating the reservoir, reconfiguring well completions, or deploying new technologies to access bypassed reserves. Additionally, offshore well interventions are vital for addressing safety and environmental concerns, such as preventing leaks, blowouts, or other hazards that can arise from aging or malfunctioning infrastructure.

- By intervening in a well, operators can restore production rates, extend the well’s lifespan, and ensure the long-term sustainability of offshore oil operations, even in deepwater or challenging environments.

Types of Offshore Oil Well Interventions

Offshore oil well interventions are classified into two main categories based on the complexity and scale of the operation: light well intervention and heavy well intervention. Each category serves different purposes and requires distinct approaches and equipment.

Light Well Intervention

Light well intervention involves relatively straightforward operations that do not require the use of a large drilling rig. Instead, LWI can be carried out using specialized vessels equipped with wireline or coiled tubing systems. These interventions are typically less intrusive, focusing on maintaining well performance, conducting inspections, or performing minor repairs.

Common examples of LWI include:

- Wireline logging and diagnostics: Tools are lowered into the well on a wireline to gather data or monitor well conditions.

- Well cleaning and maintenance: Removing obstructions or buildup in the well to improve production flow.

- Valve replacements: Simple repairs, such as replacing malfunctioning valves or seals.

LWI is often the preferred choice due to its lower cost and quicker turnaround compared to heavy interventions. It allows operators to perform necessary work without completely halting production, making it both efficient and practical for minor well issues.

Heavy Well Intervention

Heavy well intervention (HWI) is required for more complex and challenging operations that go beyond what light intervention methods can handle. HWI typically involves the use of a full drilling rig or a larger, specialized intervention vessel capable of managing more intensive repairs or modifications.

Key examples of heavy well intervention tasks include:

- Workover Operations: Pulling and replacing large downhole equipment, such as production tubing or completion systems.

- Major Repairs: Repairing damaged well components like casing or downhole safety valves.

- Well Re-entry and Sidetracking: Re-entering a well to drill additional sidetracks or access deeper reservoirs.

- Plugging and Abandonment (P&A): Permanently sealing a non-productive well to ensure environmental safety.

Heavy well interventions are more time-consuming and expensive but are essential when dealing with significant well issues or major structural damage that requires comprehensive remediation.

Routine vs. Non-routine Interventions

- Routine Interventions: These are planned, preventive measures taken to maintain optimal well performance. Routine interventions are often scheduled based on well-monitoring data and typically include cleaning, logging, and minor repairs.

- Non-routine Interventions: These are reactive operations performed to address unexpected issues, such as sudden production declines, equipment failures, or well integrity problems. Non-routine interventions can be more complex and may require immediate response to minimize downtime or prevent environmental risks.

Routine interventions are generally smaller in scale and more predictable, while non-routine interventions tend to be more urgent and resource-intensive, especially if they involve heavy well intervention techniques.

Techniques Used in Offshore Well Intervention

Offshore well intervention involves various techniques, each designed to address specific issues within the well. These techniques can range from non-intrusive methods for diagnostics and monitoring to more invasive procedures that require specialized equipment and expertise. The choice of technique depends on factors like the type of intervention (light or heavy), the complexity of the problem, and the environment in which the well operates, such as shallow or deep waters.

Wireline Operations

Wireline operations are one of the most commonly used techniques in offshore well intervention. This involves lowering a thin cable, or wireline, into the wellbore to insert tools, sensors, or equipment. Wireline techniques can be used in both open (production is stopped) and live (production continues) wells, making them highly versatile.

Wireline interventions fall into two categories:

- Slickline: Slickline uses a smooth, non-electric cable to lower tools into the well. It is primarily used for simpler operations such as setting or retrieving downhole plugs, cleaning the wellbore, or performing mechanical tasks like opening and closing valves.

- Electric Line (E-Line): E-line cables include electrical conductors, enabling the transmission of real-time data from downhole sensors. E-line is used for more sophisticated tasks such as logging, perforation, and diagnostics. By providing real-time well data, operators can better assess the condition of the well and make informed decisions regarding further intervention.

Wireline operations are fast, cost-effective, and can often be performed from a light well intervention vessel, making them ideal for routine maintenance or troubleshooting.

Coiled Tubing Operations

Coiled tubing is a continuous length of steel or composite tubing that is flexible and wound on a spool. This tubing can be inserted into the well under pressure without stopping production, allowing for more complex interventions than wireline operations. Coiled tubing can carry out a wide range of tasks, including:

- Well Cleaning: Coiled tubing is often used to remove debris, sand, or other blockages from the wellbore that restrict fluid flow. Cleaning can be done by circulating fluids or using mechanical tools attached to the tubing.

- Fluid Pumping: Operators can pump chemicals, fluids, or gases into the well through the coiled tubing to improve production. For example, acidizing treatments are often delivered through coiled tubing to dissolve blockages or improve permeability in the reservoir rock.

- Well Stimulation: Coiled tubing is used to perform hydraulic fracturing, where high-pressure fluids are pumped into the well to create fractures in the surrounding rock, enhancing oil and gas flow from the reservoir. Coiled tubing is also employed in matrix acidizing, which involves pumping acids into the well to clean the formation and improve flow paths.

Coiled tubing operations are highly versatile and can be adapted to various offshore well intervention scenarios. The ability to perform tasks without halting production makes this technique particularly valuable for maintaining well performance with minimal downtime.

Snubbing Operation

Snubbing is a specialized well intervention technique that allows for the insertion or removal of tubular components under pressure. Unlike coiled tubing, which is flexible, snubbing involves the use of rigid pipe, and it is performed when high-pressure conditions are present. Snubbing is often used in wells that cannot be killed (temporarily stopped) during the intervention due to reservoir pressure concerns.

Key uses of snubbing operations include:

- Workovers and Completions: Snubbing is employed when operators need to replace or repair sections of the wellbore while maintaining control over high-pressure fluids within the well.

- Live Well Interventions: It allows for well interventions without the need to stop production or kill the well, making it a valuable option for deep or high-pressure wells.

- Pipe Retrieval and Installation: Snubbing enables the removal or installation of production tubing, casing, or other downhole components while maintaining well integrity under high pressure.

Snubbing operations are complex and generally more expensive than coiled tubing, but they offer the unique ability to safely intervene in wells that present extreme pressure challenges.

Hydraulic Fracturing and Acidizing

Hydraulic fracturing and acidizing are stimulation techniques used to enhance production by improving the permeability of the reservoir, thereby allowing hydrocarbons to flow more easily into the wellbore.

- Hydraulic Fracturing (Fracking): This process involves injecting fluid at high pressure into the reservoir to create fractures in the rock formation. Proppants, such as sand or ceramic beads, are injected along with the fluid to hold these fractures open, ensuring that oil and gas can flow freely to the wellbore. Hydraulic fracturing is commonly used in offshore settings to stimulate low-permeability formations or revive wells with declining production.

- Acidizing: Acidizing is used to dissolve blockages or damage in the wellbore caused by scale, mineral deposits, or other obstructions that reduce flow. In this technique, acid is injected into the well to dissolve these materials, improving the well’s productivity. Matrix acidizing targets the near-wellbore area, while fracture acidizing is used to dissolve formation damage in deeper sections of the reservoir.

Both hydraulic fracturing and acidizing can significantly boost production in wells that have experienced reduced output due to damage or poor reservoir conditions.

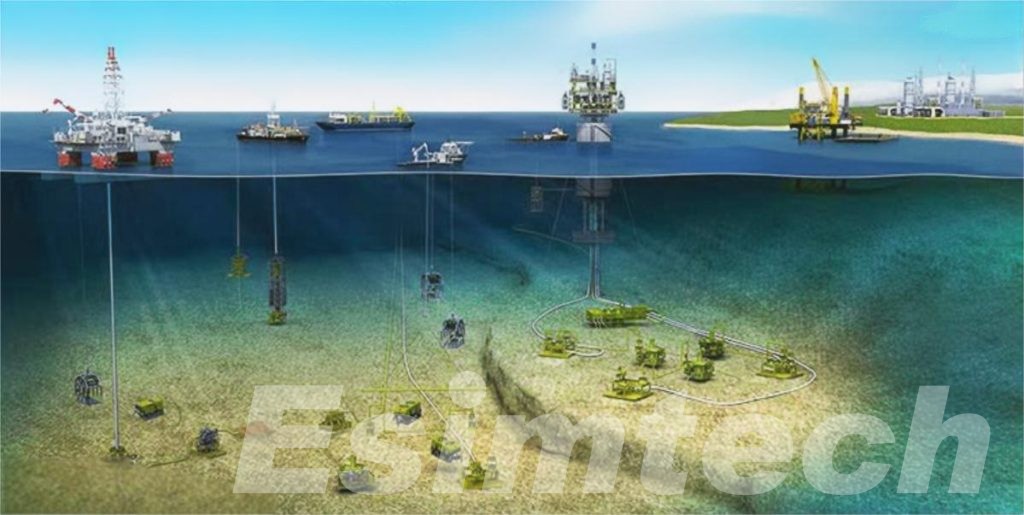

Offshore Well Intervention Vessels and Equipment

Offshore well intervention requires specialized vessels and equipment to support the operation. The type of vessel or platform used will depend on the water depth, the complexity of the intervention, and the type of equipment needed.

- Light Well Intervention Vessels (LWIVs): These vessels are designed for light interventions and are equipped with cranes, wireline, and coiled tubing systems. They are cost-effective for performing routine or minor repairs.

- Drilling Rigs: For heavy interventions, a mobile offshore drilling unit (MODU) or semi-submersible rig is often used. These rigs are equipped with the necessary tools for more complex repairs, replacements, and completions.

- Well Control Equipment: Specialized blowout preventers (BOPs) and well control devices are used to ensure safety during interventions, particularly in high-pressure environments.

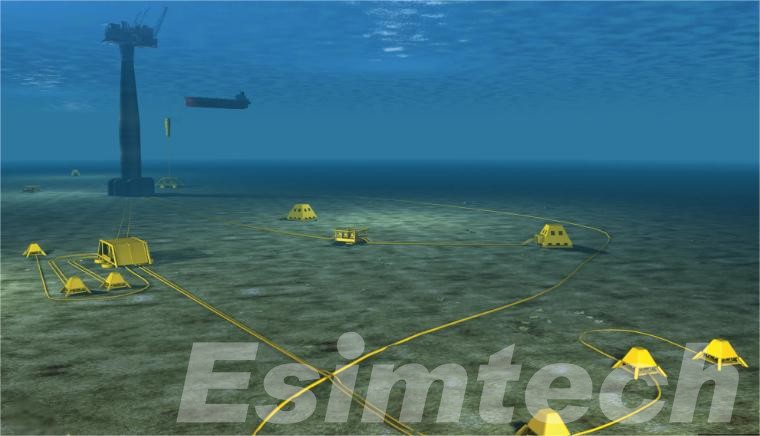

- Remotely Operated Vehicles (ROVs): ROVs are deployed for subsea well interventions, assisting in monitoring, repairs, or manipulating tools on the seafloor.

These vessels and tools enable the safe and efficient execution of interventions in challenging offshore environments, ensuring minimal downtime and operational disruptions.

Importance of Technology and Innovation

Technology and innovation are crucial in offshore well interventions, with advances in automation, robotics, and digital monitoring improving accuracy and efficiency. Real-time data from downhole sensors help engineers predict issues and plan proactive interventions. Innovations like electric wireline systems, enhanced coiled tubing, and advanced simulation software reduce intervention time and costs. Subsea technology improvements also allow interventions in ultra-deepwater environments once inaccessible.

As the oil and gas industry tackles challenges like aging infrastructure and declining production, technological advancements play a vital role in maximizing well productivity while upholding safety and environmental standards.

Offshore oil well intervention is a vital aspect of maintaining and optimizing production in offshore oil fields. Through a combination of techniques, vessels, and innovative technologies, operators can address both routine and unexpected challenges to keep wells productive and safe, even in some of the most challenging environments on Earth.