What is Measurement While Drilling in Oil and Gas

What is Measurement While Drilling?

Measurement While Drilling (MWD) is a crucial technology in the oil and gas industry, providing real-time data about the drilling environment while the well is being drilled. This system allows operators to monitor key parameters such as wellbore trajectory, formation characteristics, and drilling conditions, enhancing both safety and efficiency. Unlike conventional drilling methods, MWD eliminates the need to halt drilling operations to take measurements, which significantly reduces downtime and operational costs.

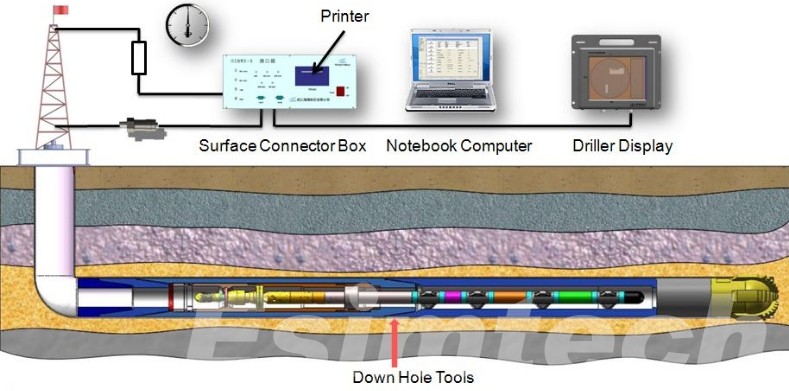

MWD systems transmit data from downhole sensors to the surface in real-time, using mud-pulse telemetry, electromagnetic waves, or other communication techniques. This continuous flow of information enables precise drilling, ensuring that the well remains on target and that the drilling process avoids hazardous formations.

Role of Measurement While Drilling

The primary role of MWD in the oil and gas industry is to provide real-time feedback during the drilling process. This data informs the drilling crew about the well’s direction, inclination, and position, as well as critical downhole conditions such as pressure, temperature, and formation porosity. MWD helps operators adjust the drilling path as necessary to stay within the geological target zone, which is especially critical in horizontal or directional wells.

Another important function of MWD is to enhance wellbore stability. By monitoring real-time data, operators can identify and react to potential problems, such as sudden changes in formation pressure, that could compromise the structural integrity of the well.

Components of Measurement While Drilling System

The Measurement While Drilling (MWD) system consists of several integrated components, each playing a critical role in capturing, transmitting, and interpreting real-time downhole data.

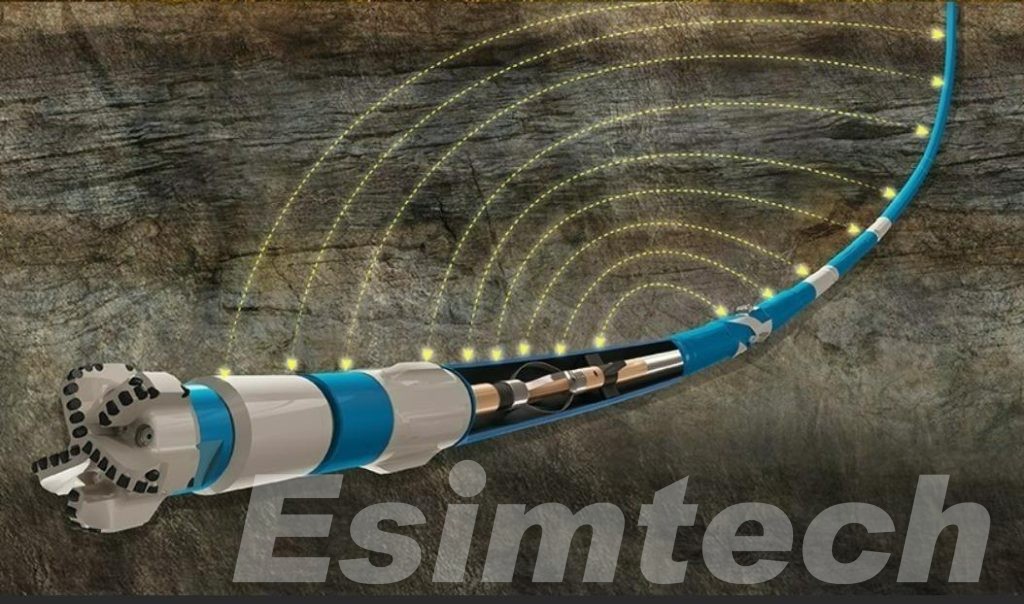

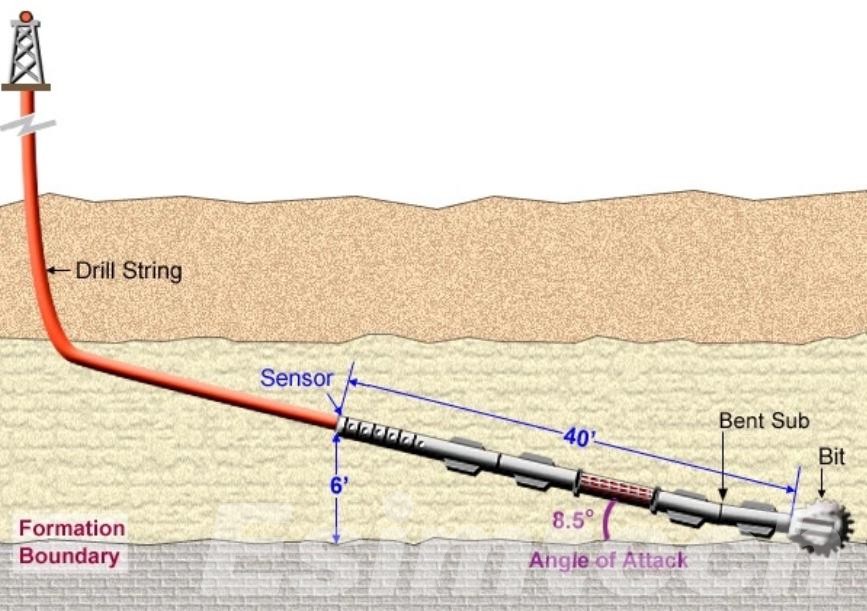

- Downhole Sensors: These sensors are placed near the drill bit to measure essential parameters like inclination, azimuth, temperature, and pressure. The inclination and azimuth sensors help determine the exact direction and angle of the wellbore, ensuring that it follows the planned trajectory. Other sensors can also provide additional data on formation characteristics, including porosity and resistivity, which are useful for geosteering and formation evaluation.

- Telemetry Unit: This unit is responsible for transmitting the data gathered by the downhole sensors to the surface in real-time. The most common method used for communication is mud-pulse telemetry, which creates pressure pulses in the drilling fluid (mud) to encode information. Alternatives include electromagnetic telemetry and acoustic systems, which may be used in specific conditions like deepwater drilling or in wells with low mud flow.

- Surface Equipment: Once the telemetry unit transmits the data, surface equipment decodes the signals and converts them into readable formats. These systems include mud-pulse receivers or electromagnetic signal receivers, which then relay the data to computer systems that display the information for the drilling crew.

- Power Source: MWD systems typically require a robust downhole power supply. This is often achieved through a turbine generator powered by the flow of drilling fluid or via lithium batteries for shorter operations. The power source ensures the continuous operation of sensors and telemetry units during the drilling process.

Each of these components works in unison to provide critical insights that enable safe, precise, and efficient drilling operations.

Measurement While Drilling vs. Directional Drilling

Measurement While Drilling (MWD) and directional drilling are closely related technologies that are often used together in oil and gas exploration. However, they serve distinct roles within the drilling process, with each contributing to the overall success of wellbore navigation and resource extraction.

Directional Drilling

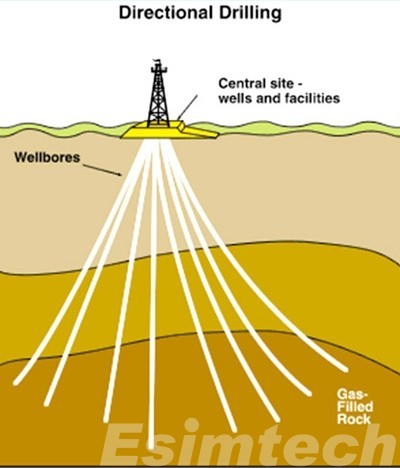

Directional drilling refers to the technique of steering a wellbore along a pre-defined path rather than drilling straight down. This approach is essential for reaching oil and gas reserves that are not directly beneath the drilling rig or for optimizing access to a reservoir by drilling horizontally through it. This capability is crucial in modern oil and gas exploration, particularly in areas with dense or multiple reservoirs, where vertical drilling might be inefficient or impossible.

Directional drilling allows the operator to:

- Access reservoirs that are laterally offset from the drilling location.

- Drill multiple wells from a single platform or well pad, minimizing surface disruption.

- Avoid obstacles such as existing wells or geological faults.

- Reach specific parts of a reservoir to maximize production.

Achieving the required accuracy in directional drilling involves advanced techniques and tools like rotary steerable systems (RSS) and mud motors. However, the ability to guide the drill bit to a precise location depends on real-time data to adjust the drilling trajectory as needed, which is where MWD comes into play.

Measurement While Drilling (MWD)

MWD systems provide real-time information that helps guide the directional drilling process. Without MWD, directional drilling would involve more guesswork and periodic pauses to measure and correct the trajectory. MWD eliminates these interruptions by continuously supplying data on the well’s position, orientation, and downhole conditions, allowing for immediate adjustments to the drilling path.

In addition to aiding in wellbore navigation, MWD offers critical insights into the formation’s characteristics, helping operators optimize well placement and avoid hazards. The real-time nature of MWD makes it indispensable in maintaining precise control over the drilling process, reducing non-productive time (NPT), and improving drilling accuracy and safety.

Key Differences Between MWD and Directional Drilling

While MWD and directional drilling are complementary, they differ in purpose and function. The table below summarizes the key differences:

| Aspect | Measurement While Drilling (MWD) | Directional Drilling |

| Primary Function | Provides real-time data on wellbore trajectory and downhole conditions | Controls the physical path of the wellbore |

| Key Role | Monitors and transmits critical measurements (inclination, azimuth, pressure, etc.) | Guides the drill bit to a specific target or along a specific trajectory |

| Real-Time Feedback | Yes, continuous transmission of data while drilling | Relies on MWD or other tools for feedback |

| Main Purpose | Enhances precision and safety during drilling, supports geosteering | Enables the wellbore to deviate from a straight vertical path |

| Technology Involved | Includes downhole sensors, telemetry units, and surface receivers | Utilizes steerable tools like rotary steerable systems (RSS) or mud motors |

| Formation Evaluation | Provides information about formation properties, aiding in reservoir assessment | Mainly focused on hitting target zones and avoiding obstacles |

| Efficiency | Reduces non-productive time by providing continuous measurements | Optimizes well placement to maximize production and reservoir access |

| Dependency | Can be used independently or in conjunction with directional drilling | Typically relies on MWD for accurate wellbore positioning |

MWD and directional drilling are tightly integrated into modern drilling operations. MWD provides real-time data on wellbore position, inclination, and downhole conditions, which helps guide directional drilling. In complex environments, such as offshore or shale formations, the combination of MWD and directional drilling enhances well precision, reduces risks, and maximizes production by enabling more informed, real-time decision-making. Together, they improve the overall efficiency and success of drilling operations.

Applications of Measurement While Drilling in Oil and Gas

Measurement While Drilling (MWD) technology has a wide range of applications in the oil and gas industry, enhancing various aspects of drilling operations and reservoir management.

- Directional and Horizontal Drilling: MWD systems are critical for guiding the drill bit along precise paths, especially in directional and horizontal drilling. This capability allows operators to drill wells that deviate from a vertical path to access off-grid reservoirs or multiple targets from a single location, optimizing resource extraction and minimizing surface disruption.

- Geosteering: MWD enables real-time geosteering, where operators adjust the drilling trajectory based on formation data. By continuously monitoring formation characteristics such as porosity and resistivity, MWD helps in steering the drill bit towards the most productive zones within a reservoir, enhancing recovery rates and ensuring the well is optimally placed.

- Formation Evaluation: MWD provides valuable information about formation properties, such as pressure, temperature, and lithology, which is essential for evaluating reservoir quality. This data supports decisions on well completion, hydraulic fracturing, and other production techniques, ensuring that the well is developed in the most efficient and effective manner.

- Drilling Optimization: By offering real-time insights into downhole conditions, MWD allows for the fine-tuning of drilling parameters, such as weight on bit and rotation speed. This optimization reduces drilling time, minimizes non-productive time (NPT), and lowers overall operational costs.

- Well Control and Safety: MWD systems improve well control by monitoring for signs of potential problems, such as abnormal pressure changes or wellbore instability. Early detection of these issues helps prevent blowouts or other hazardous events, enhancing safety and operational reliability.

Overall, MWD technology plays a pivotal role in modern drilling operations, driving efficiency, safety, and productivity across various stages of well development and production.

Summary

All in all, Measurement While Drilling (MWD) is an essential technology in modern oil and gas operations, offering real-time data that improves well accuracy, safety, and efficiency. The system plays a key role in supporting directional drilling, ensuring wellbore stability, and optimizing hydrocarbon recovery. By combining advanced sensors, telemetry systems, and surface equipment, MWD enables continuous monitoring of downhole conditions, making it a critical tool for successful drilling operations.