What is Gas Injection Enhanced Oil Recovery in Oil and Gas Industry

EOR is an invaluable tool in the oil and gas industry for extracting additional hydrocarbons that cannot be recovered through traditional means. Of all EOR methods available today, Gas Injection Enhanced Oil Recovery stands out due to its efficiency and adaptability.

This article delves into the fundamentals and techniques associated with gas injection EOR as well as recent technological advancements shaping its future.

Fundamentals of Gas Injection Enhanced Oil Recovery

Gas Injection Enhanced Oil Recovery (EOR) is a technique designed to extract more crude oil from reservoirs after other recovery methods have failed, through injection of carbon dioxide, natural gas, or nitrogen into the reservoir to increase oil flow and boost recovery rates.

How Gas Injection Works

Here are the general steps gas injection works:

- Pressure Maintenance: As natural reservoir pressure dips, gas injection helps restore and sustain production by keeping pressure stable in order to continue oil output.

- Oil Viscosity Reduction: Gas injection into crude oil reduces its viscosity, making production wells more accessible by creating easier flow conditions for production wells.

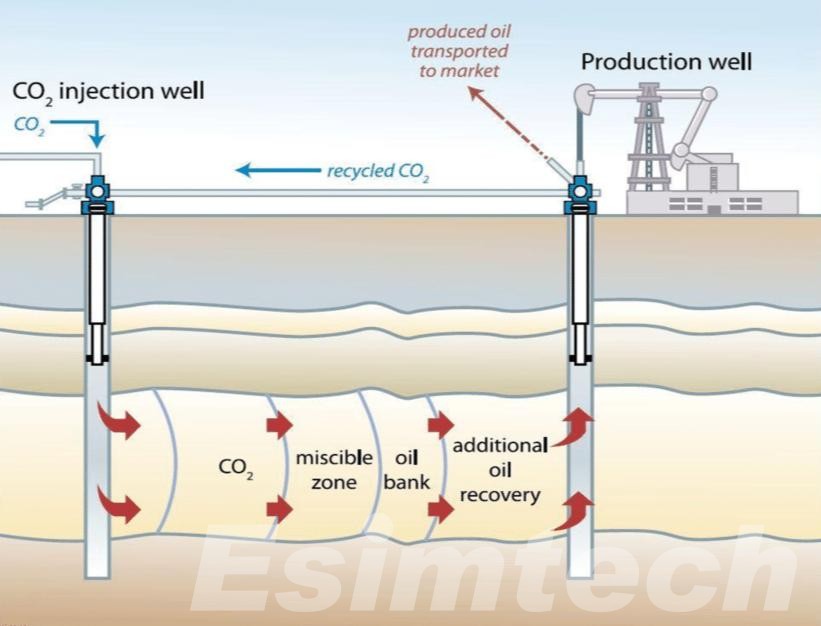

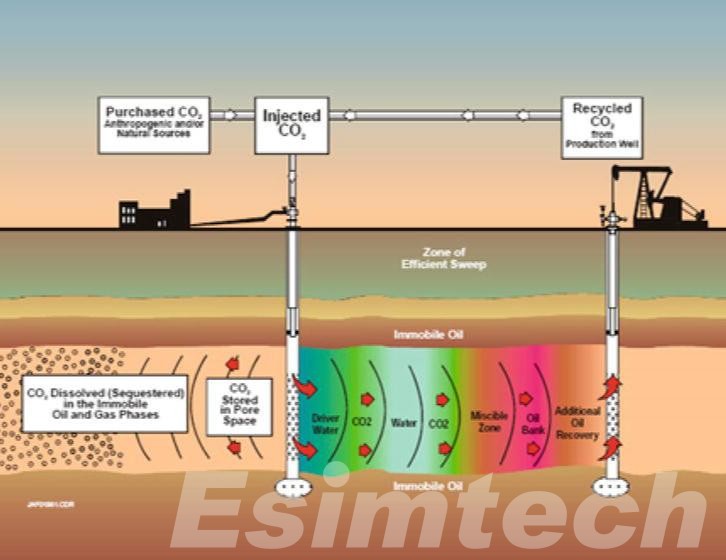

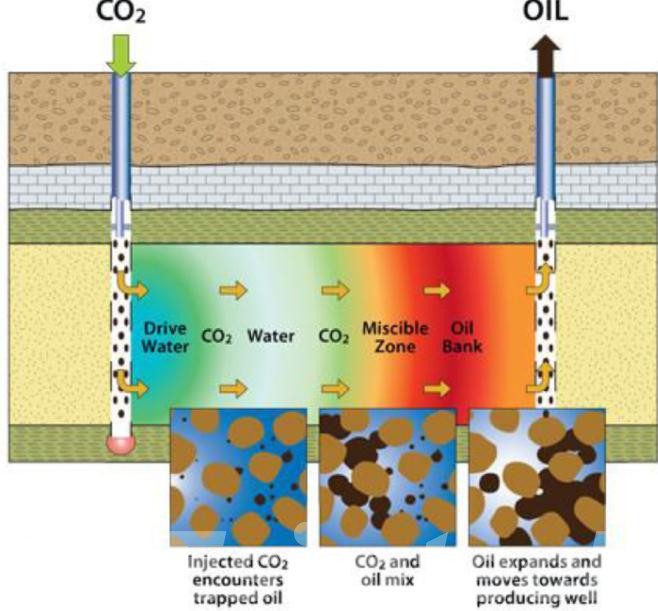

- Oil Swelling and Displacement: Certain gases (like CO2) dissolve into oil, causing it to expand (swell up) and push more of its content towards extraction points. Gas injection helps displace oil trapped under surfaces and enhance sweep efficiency.

- Improved Recovery Mechanisms: Miscible gas injection entails mixing the gas fully with oil to eliminate surface tension for improved flow. Immiscible injection uses gas as an engine for pushing oil without fully mixing the two substances.

Gas injection can be miscible (where the gas fully mixes with oil) or immiscible (where it does not fully dissolve but still aids recovery). The choice depends on reservoir conditions, oil type, and economic factors.

This method is particularly effective in mature fields where conventional extraction methods no longer suffice, making it a key strategy for maximizing oil recovery worldwide.

Types of Gas Injection EOR Techniques

Gas injection Enhanced Oil Recovery techniques can be divided into categories according to how injected gas interacts with crude oil in a reservoir, offering various levels of recovery depending on factors like reservoir pressure, oil composition and temperature. There are four general kinds of EOR:

Miscible Gas Injection

Miscible gas injection takes place when an injected gas mixes entirely with reservoir oil under specific pressure and temperature conditions to form one continuous phase, significantly decreasing oil viscosity and interfacial tension and permitting freer oil flow towards production wells. Common miscible gases include carbon dioxide (CO2) or hydrocarbon gases such as methane/natural gas liquids.

This method has proven its worth time after time when applied properly to light to medium oil reservoirs, providing high recovery efficiencies when employed appropriately.

Immiscible Gas Injection

With this approach, injected gases don’t fully mix with crude oil – instead they increase reservoir pressure by displacer it through physical forces and raise pressure in order to displace more oil by pushing from above through physical force. Although immiscible injection yields lower recovery compared to miscible injection, immiscible injection can still prove valuable in reservoirs that don’t permit miscibility due to pressure or composition constraints – nitrogen and methane are often utilized by this approach.

Carbon Dioxide (CO2) Injection

CO2 injection is one of the most frequently employed gas EOR methods. Depending on reservoir conditions, CO2 may be introduced either miscibly or immiscibly into oil reservoirs for injection; when miscible forms emerge it dissolves directly in oil reservoirs to decrease viscosity while increasing mobility and environmental goals via carbon capture storage (CCS) initiatives.

Water-Alternating-Gas (WAG) Injection

WAG Injection combines the advantages of gas and water injection into one, by switching back and forth between injecting gas and water into a reservoir in order to increase sweep efficiency while decreasing gas channeling issues that typically arise whereby too much gas enters production wells too rapidly and reduces effectiveness. WAG can be optimized specifically to increase oil recovery through altering cycle ratio or volume settings, making WAG particularly suitable for heterogeneous reservoirs where this technique will maximize oil recovery by fine tuning cycle ratio or volume settings to optimize oil recovery by changing cycle ratio/volume settings accordingly.

Technological Advancements in Gas Injection EOR

Gas Injection Enhanced Oil Recovery has undergone major transformation in recent years due to advances in engineering, data analytics and sustainability goals. These innovations have seen efficiency increased, operational costs reduced significantly while expanding application of these techniques on more complex reservoirs.

1. Advanced Reservoir Simulation and Modeling

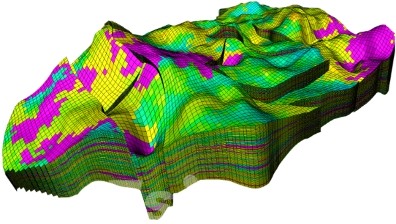

Contemporary simulation software leverages high-resolution data and machine learning algorithms to accurately model reservoir behavior, providing engineers with unprecedented predictions of gas movement, miscibility zones and recovery rates allowing better planning strategies and injection strategies.

2. Real-Time Monitoring and Automation

Modern oilfield technologies enable real-time monitoring and automation to keep production performance under optimal condition while automating injection parameters to achieve optimal recovery while minimising gas loss or channeling. Automated control systems adjust injection parameters in real-time for maximum recovery while minimising gas loss or channeling.

3. Digital Twin and AI Integration

Digital twins–virtual models of reservoirs–and AI analytics allow operators to test various gas injection scenarios prior to applying them in the field, helping reduce risks, save time, and optimize recovery rates by identifying effective injection patterns. This enables operators to take an unbiased approach towards gas injection.

4. Enhancing CO2 Capture, Utilization and Storage (CCUS)

CO2 injection has become one of the primary gas EOR methods. Thanks to improvements in capture technologies and an expanded CO2 pipeline infrastructure, operators are now able to access CO2 more efficiently at lower costs; not only enhancing oil recovery but also helping lower greenhouse gas emissions.

5. Hybrid EOR Techniques

Combining gas injection with other EOR methods such as polymer flooding, surfactant injection or thermal technologies has proven extremely successful for treating challenging reservoirs. Such hybrid approaches help enhance sweep efficiency while increasing oil displacement across heterogenous formations.

To Conclude

Gas Injection Enhanced Oil Recovery is an established and ever-evolving approach to increasing oil production from mature and unconventional reservoirs. Utilizing techniques like miscible, immiscible and cyclic gas injection, industry professionals have successfully maximized recovery rates through this practice.

Recent advances like CO2-EOR with CCS, smart monitoring systems and nano-enhanced gases are revolutionizing this process and making it more cost effective and eco-friendly.

As oil demand remains at record levels, gas injection EOR remains an indispensable technology to maximize hydrocarbon recovery while meeting global energy transition goals.