What is A Drill Ship Rig: Key Components and Functions, Challenges and Environmental Concerns

A drill ship rig is a spectacular and adaptable engineering wonder in the realm of offshore oil and gas drilling. These vessels combine the capability of a standard drilling rig with the mobility of a ship, allowing them to access remote and difficult offshore places. This article digs into the fascinating world of a drill ship rig, covering its architecture, functions, and critical role in unleashing significant energy resources beneath the seabed.

What are the Key Components and Features of A Drill Ship Rig

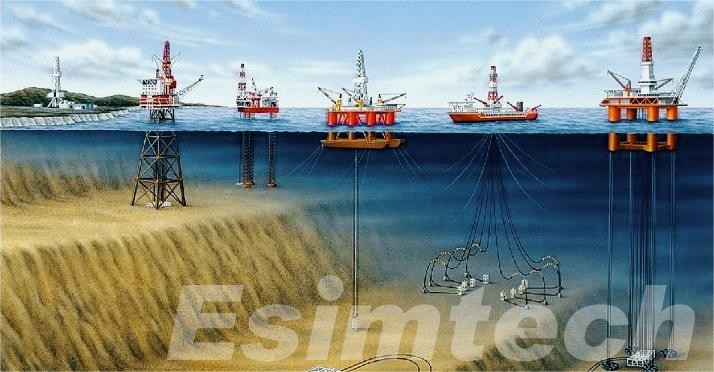

A drill ship rig is a specialized vessel designed for offshore drilling operations. Unlike traditional stationary oil drilling rigs fixed to the ocean floor, drill ships are self-propelled and can navigate to various drilling locations. This mobility allows them to access deepwater reserves in remote and challenging environments, making them a vital asset in the oil and gas industry.

Drilling Equipment

Drilling Derrick: The drilling derrick is a tall structure that supports the drilling equipment. It is frequently outfitted with a hoisting mechanism for raising and lowering the drill string and other oil drilling tools.

Drilling Machinery: Drill ships are outfitted with strong drilling equipment, such as drill bits and rotary systems, to construct boreholes in the seabed.

Blowout Preventer (BOP) System: This crucial safety element is intended to avoid uncontrolled hydrocarbon discharge during drilling operations. It has numerous valves and control systems.

Dynamic Positioning System (DPS)

A DPS is a combined system of thrusters and sensors that allows the drill ship to maintain a constant position above the drilling site. This is essential for precise drilling in deep water and under difficult environmental circumstances.

Storage and Processing Facilities

Mud and Fluid Storage: Drill ships have separate tanks for storing drilling mud and other fluids necessary in the drilling operation. These fluids are required to keep the drill bit cold and maintain pressure.

Casing and Drill Pipe Storage: Casing and drill pipes, which are needed to line and stabilize the wellbore during drilling, are stored in designated sites.

Hydrocarbon Processing: Many drill ships have hydrocarbon processing facilities. This includes separation systems to separate oil, gas, and water, as well as storage tanks for recovered oil.

Accommodation and Support Facilities

Crew Accommodation: Drill ships are equipped with extensive safety systems, including fire detection and suppression systems, lifeboats, and safety equipment for crew members. Safety drills and procedures are regularly conducted to ensure preparedness.

Supplies and Equipment Storage: There are storage spaces for supplies, spare parts, and equipment, allowing the rig to function autonomously for lengthy periods of time.

Workshops: Small workshops are frequently present for maintenance and repair.

Helideck

A helideck or helipad is required for crew changes as well as the transport of supplies and equipment. It enables helicopters to securely land on the drill ship, easing logistical and personnel rotations.

Control Room and Monitoring Systems

Modern drill ships are outfitted with sophisticated control rooms that monitor and control drilling operations. These chambers are equipped with advanced computer systems that offer real-time data on drilling parameters.

Safety Systems

A drill ship is equipped with significant safety measures, such as fire detection and suppression systems, lifeboats, and crew safety equipment. To maintain readiness, safety drills and procedures are undertaken on a regular basis.

Power Generation and Propulsion

Drill ships are equipped with massive generators and propulsion systems, generally with several engines and propellers, to power the many systems onboard and provide propulsion.

Subsea Equipment

Risers and umbilicals connect subsea wellheads and control systems to the drill ship. These components enable the well to be safely drilled, controlled and maintained.

Communication Systems

Drill ships are outfitted with sophisticated communication gear, including satellite links, to keep in touch with onshore offices and assure safety and operational coordination.

Environmental Protection Systems

To minimize the environmental impact, drill ships are equipped with systems to collect and treat wastewater and manage waste disposal. They also have spill response equipment on hand.

Mooring Systems

Some drill ships may have mooring systems in addition to dynamic positioning systems. These systems use anchors or other means to secure the vessel in position during drilling.

Drill ship rigs are extremely capable and self-sufficient platforms for offshore drilling operations, capable of functioning in some of the most demanding marine environments, thanks to these main components and features.

What are Functions and Capabilities of A Drill Ship Rig

Deepwater Drilling

Drill ship rigs are specifically constructed for deepwater operations, typically reaching depths of thousands of meters below the sea surface. At these high depths, their dynamic positioning systems assure precise drilling.

Exploratory Drilling

A drill ship is essential in exploratory drilling, assisting energy corporations in identifying possible oil and gas reserves. Drilling test wells to assess the nature and quantity of hydrocarbons in subsea deposits is part of this process.

Production Drilling

Drill ships can be used for production drilling, extracting oil and gas from the seabed, after successful exploration. They serve as a mobile production platform, which can be advantageous in rapidly depleting reservoirs.

Rapid Deployment

Drill ship rigs can be readily transported to new drilling locations, allowing energy corporations to adapt fast to changing market conditions and exploratory prospects.

What are the Challenges and Environmental Concerns for A Drill Ship Rig

While drill ship rigs provide substantial advantages in offshore drilling, they also present a number of problems and environmental concerns that must be addressed in order to maintain safe and sustainable operations.

Environmental Impact

Oil Spills: Oil spills can occur accidentally during drilling or transport activities, posing a serious hazard to marine ecosystems. To mitigate these dangers, strict spill response strategies and equipment are required.

Disruption of Marine Life: Drill ships have the potential to harm local marine ecosystems, including habitats for fish, coral, and other species. Anchor placement and drilling activities can cause noise pollution and physical problems.

Safety Risks

Blowouts: Despite safety measures like blowout preventers (BOPs), blowouts (uncontrolled releases of oil and gas) can still happen, potentially leading to catastrophic accidents similar to the Deepwater Horizon incident in 2010.

Fire and Explosion: The presence of flammable materials, equipment, and drilling operations on drill ships increases the risk of fires and explosions, endangering both personnel and the environment.

Regulatory Compliance

Drill ship operations are subject to a complex web of international, national, and regional regulations. Ensuring compliance with these regulations is challenging and requires continuous monitoring and adaptation to evolving standards.

Weather and Environmental Conditions

A drill ship often operate in remote and harsh environments, including extreme weather conditions and extreme temperatures. These conditions can make drilling operations challenging and increase the risk of accidents.

Deepwater Challenges

Deepwater drilling poses unique challenges due to the high pressures and temperatures encountered at depth. It requires advanced technologies and equipment to handle these conditions safely.

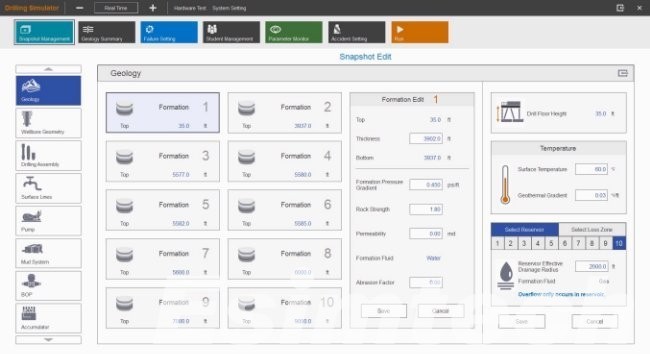

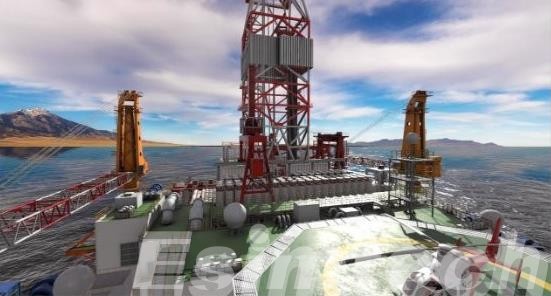

Simulation is critical in managing the inherent dangers of deepwater drilling operations. The drilling simulation system aids to safer, more efficient, and environmentally friendly operations.

Workers receive rigorous simulation-based training before heading into the dangerous deep water area. Workers can use simulators to familiarize themselves with subsea equipment, practice emergency response procedures, and build proficiency in operating ROVs safely.

Oil simulation software is used to thoroughly examine the potential environmental impact of deep water operations. Operators can design methods to reduce their ecological footprint by simulating various situations, ensuring that their actions comply with environmental standards and industry best practices.

Resource Depletion

The exploration and production of oil and gas can lead to the depletion of finite resources. Drill ships enable access to previously untapped reserves, which may contribute to increased resource extraction and associated environmental impacts.

Waste Management

Drill ship operations generate various types of waste, including drilling muds, cuttings, and produced water. Proper disposal and treatment of these waste materials are essential to minimize environmental harm.

Climate Change Considerations

Extraction and combustion of fossil fuels, particularly those derived via drill ship operations, contribute to greenhouse gas emissions and climate change. This creates long-term environmental issues that must be addressed.

Accidental Discharges

Aside from oil spills, inadvertent chemical, drilling fluid, or waste material releases can also impact marine life and ecosystems.

Stranding Risk

Drill ships’ mobility raises the potential of unintentional grounding or stranding, which can harm sensitive marine environments and create spills or leaks.

To address these difficulties and concerns about the environment, industry players, regulatory agencies, and environmental organizations work together to create and implement best practices and safety measures. This includes strict safety measures, greater spill response capabilities, the development of more environmentally friendly drilling fluids, and increased industry transparency and accountability. Additionally, advancements in oil and gas simulation technology and increased emphasis on environmental stewardship are driving innovations to reduce the environmental impact of drill ship operations and ensure a sustainable future for offshore drilling.

Summary

A drill ship rig is a significant advancement in the world of offshore drilling, allowing energy corporations to access deepwater deposits and explore new frontiers in the search for hydrocarbon resources. These cutting-edge vessels combine mobility, cutting-edge technology, and varied functionality to conduct exploratory and production drilling operations in harsh offshore settings. However, its use entails responsibility to reduce environmental damage and maintain safety standards. Drill ship rigs will continue to play an important part in the global energy economy as technology advances.