What do You Know about Offshore Oil Production

Offshore oil production is a significant contributor to the global energy supply, providing a substantial portion of the world’s crude oil and natural gas. As land-based oil rigs become more challenging to access, energy companies have increasingly turned to offshore drilling to meet rising energy demands. This method involves extracting petroleum from beneath the ocean floor using advanced technologies and specialized infrastructure. As global energy demand continues to rise, offshore drilling has expanded to deeper waters and more remote locations, supported by technological advancements that enhance efficiency and safety.

Understanding the Process of Offshore Oil Production

This process of offshore oil production ensures efficient and safe extraction while balancing environmental and operational challenges.

| Stage | Key Activities | Technologies/Methods Used |

| Exploration | Seismic surveys, geological analysis, and exploratory drilling | 3D seismic imaging, geophysical mapping, test drilling |

| Appraisal | Drilling additional wells to confirm reservoir size and quality | Appraisal wells, core sampling, well logging |

| Development Planning | Designing extraction infrastructure, selecting drilling techniques | Reservoir modeling, subsea system design, platform selection (FPSO, TLP, etc.) |

| Drilling & Well Construction | Creating wells for oil extraction, installing casing, and cementing | Directional drilling, managed pressure drilling, ROVs |

| Production & Extraction | Pumping oil from the reservoir to the surface, maintaining reservoir pressure | Artificial lift systems, enhanced oil recovery (EOR), multiphase pumping |

| Processing & Storage | Separating oil, gas, and water; storing and preparing for transportation | Floating Production Storage and Offloading (FPSO), separators, dehydration units |

| Transportation | Moving crude oil to refineries via pipelines or tankers | Subsea pipelines, shuttle tankers, LNG carriers |

| Decommissioning | Shutting down depleted wells, removing infrastructure, and environmental restoration | Plugging and abandonment (P&A), rig decommissioning, subsea recovery |

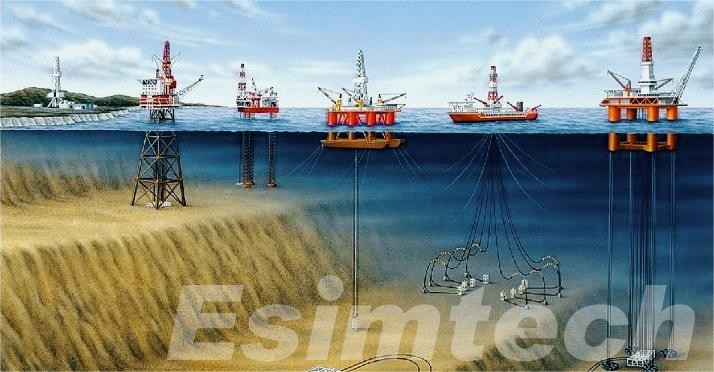

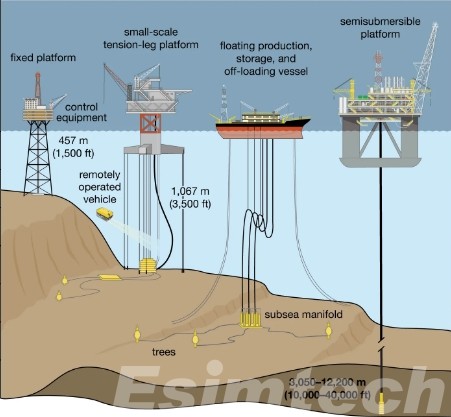

Types of Offshore Oil Rigs

These offshore oil rigs are specially designed to accommodate different offshore drilling environments, from shallow waters to extreme depths, and are crucial for extracting oil from under the seabed.

| Rig Type | Water Depth | Key Features | Common Applications |

| Jack-up Rig | Shallow to Medium Depth (Up to 500m) | Rigs mounted on a movable platform with legs that can be lowered to the seabed | Shallow water drilling, temporary operations |

| Semi-Submersible Rig | Medium to Deep Water (Up to 3,000m) | Floating platform with pontoons and columns submerged underwater for stability | Deepwater and harsh environmental conditions |

| Drillship | Deep Water (Up to 3,000m+) | Ship-shaped with a dynamic positioning system, capable of drilling in extreme depths | Ultra-deepwater drilling, flexible for various locations |

| Compliant Tower | Deep Water (500m to 1,000m) | Fixed platform anchored to the seabed with flexible mooring systems, resistant to harsh sea conditions | Deepwater fields, areas with high winds and currents |

| Tension-Leg Platform (TLP) | Deep to Ultra-Deep Water (Up to 1,500m) | Floating platform moored with vertical tendons, designed to reduce movement | Ultra-deepwater and deepwater exploration and production |

| Submersible Rig | Shallow to Medium Depth (Up to 500m) | Floating rig submerged below the water’s surface, supported by large pontoons | Shallow water and stable environments |

| Fixed Platform Rig | Shallow to Medium Depth (Up to 500m) | Platform anchored directly to the seabed, with a stable structure | Fixed operations, shallow water production |

| FPSO (Floating Production Storage and Offloading Unit) | Deep Water (Up to 3,000m+) | Floating unit for oil extraction, storage, and offloading to tankers | Remote offshore production fields, deepwater fields |

Challenges in Offshore Oil Production

Offshore oil production, while vital to meeting global energy demands, comes with its own set of unique challenges. These challenges range from harsh environmental conditions to high operational costs and significant safety concerns.

- Harsh Environmental Conditions

Offshore oil rigs are often located in remote and harsh environments, including deep ocean waters, where extreme weather conditions such as storms, high winds, and large waves can severely impact operations. These conditions make drilling, extraction, and transportation difficult, requiring specialized equipment and technology to ensure safety and efficiency.

- High Operational Costs

The cost of offshore oil production is considerably higher than land-based drilling due to the need for specialized equipment, transport, and facilities. Platforms, rigs, and vessels used in offshore production are complex and expensive to build, operate, and maintain. These high operational costs can be a barrier to investment, especially when global oil prices fluctuate.

- Safety and Risk Management

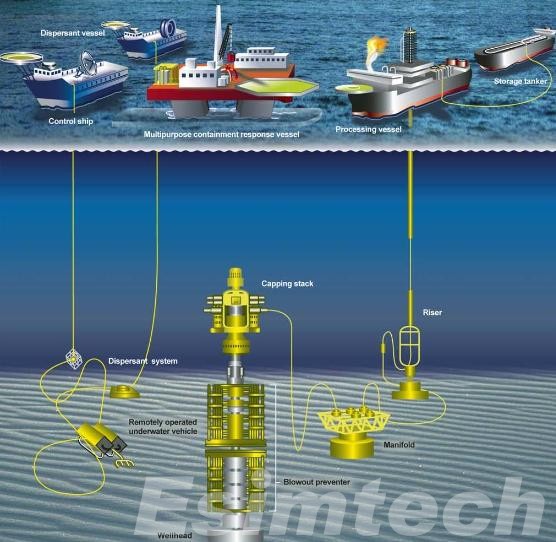

Offshore oil production involves numerous risks, including the potential for accidents such as oil spills, fires, and explosions. The Deepwater Horizon disaster of 2010 serves as a stark reminder of the catastrophic consequences that can result from a failure in offshore operations. Safety measures, training, and emergency response strategies are crucial in minimizing these risks, but the complex nature of offshore drilling makes complete risk elimination challenging.

- Technological Complexity

Offshore oil extraction requires sophisticated technology for drilling, monitoring, and maintenance. The need to operate in deep waters with high-pressure and high-temperature conditions demands advanced equipment capable of handling these environments. Additionally, subsea production systems, floating rigs, and real-time data monitoring systems require ongoing innovation and maintenance to function optimally.

- Environmental Impact and Regulation

Environmental concerns related to offshore oil production, including the risk of oil spills and pollution, are major challenges. Regulatory bodies around the world have strict guidelines to ensure that offshore drilling operations adhere to environmental protection standards. However, even with the latest technology, accidents can still occur, potentially causing long-term damage to marine ecosystems and coastal areas.

- Infrastructure and Transportation

Transporting oil from offshore platforms to refineries or markets involves complex logistics, especially when rigs are located far from shore. Pipelines, tankers, and other transportation systems need to be robust, and the infrastructure required to support these systems can be expensive to develop and maintain. In remote locations, the lack of existing infrastructure adds additional challenges to the process.

- Subsea Reservoir Management

Managing subsea reservoirs at great depths presents another challenge for offshore oil producers. Extracting oil from these reservoirs requires advanced techniques to maintain pressure and manage well integrity. Reservoir depletion and water encroachment issues can reduce the efficiency of extraction over time, leading to declining production rates and additional investment in enhanced oil recovery (EOR) methods.

- Supply Chain and Workforce Logistics

Offshore oil production requires a well-coordinated supply chain to deliver equipment, fuel, and other resources to platforms, often in remote locations. Logistics are complicated by the need to transport supplies by ship or helicopter, and the workforce stationed on rigs may work in isolated and challenging conditions for extended periods. Managing crew rotations, maintaining crew health and safety, and ensuring access to necessary supplies can be difficult.

- Climate Change and Rising Sea Levels

Climate change poses long-term risks to offshore oil operations. Rising sea levels and more frequent and intense storms could threaten offshore platforms, necessitating expensive upgrades to existing infrastructure. Additionally, stricter environmental regulations are likely to emerge as governments around the world intensify efforts to combat climate change, making future offshore drilling operations more complex and costly.

Key Innovations in Offshore Oil Production

Offshore oil production has always been a dynamic industry, driven by advancements in technology and a constant need to adapt to challenging and changing conditions. Over the years, technical innovations have emerged that have transformed offshore drilling, making it safer, more efficient, and more environmentally friendly.

- Deepwater Drilling Technology

One of the most significant innovations in offshore oil production has been the development of deepwater drilling technologies. The ability to drill in waters exceeding 10,000 feet has opened up new frontiers for oil exploration. Techniques such as drillships and semi-submersible platforms allow for efficient drilling at great depths. These advancements enable operators to access previously untapped reserves, providing a substantial increase in oil production capabilities.

- Subsea Production Systems

Subsea technology has drastically changed the offshore oil industry. Subsea production systems (SPS) allow for the extraction of oil directly from the seabed without the need for large surface platforms. These systems consist of subsea wells, pumps, and manifolds that are placed on the ocean floor, reducing the environmental footprint and operational costs. Subsea technology has expanded production capabilities in deeper waters, particularly in regions like the Gulf of Mexico and offshore Brazil, where subsea fields are abundant.

- Floating Production Storage and Offloading (FPSO) Units

FPSO units have revolutionized offshore oil production by enabling oil extraction and processing in remote, deep-water locations where building traditional infrastructure would be unfeasible. FPSOs are floating vessels that process, store, and offload crude oil to tankers. They can be relocated to different fields and are capable of operating in waters as deep as 10,000 feet. These units have made it possible to access oil reserves in deep and ultra-deep waters, such as the pre-salt fields offshore Brazil, that were once out of reach.

- Automation and Digitalization

The integration of automation and digital technology in offshore oil production is improving efficiency and safety. Real-time data monitoring systems allow operators to collect data from various sensors and equipment, enabling predictive maintenance and real-time decision-making. Artificial intelligence (AI) and machine learning algorithms are increasingly being used to optimize drilling processes, improve reservoir management, and reduce downtime. Automation also extends to drilling robots and remote-controlled equipment that can operate in hazardous environments, minimizing human risk.

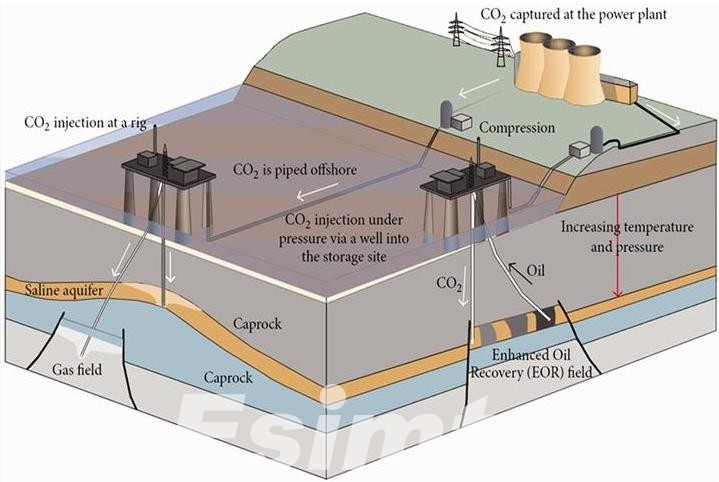

- Enhanced Oil Recovery (EOR) Techniques

As offshore oil reservoirs begin to deplete, the industry is turning to Enhanced Oil Recovery (EOR) techniques to maximize production. These techniques inject substances like water, gas, or chemicals into the reservoir to increase pressure and stimulate additional oil flow. Innovations in EOR, including CO2 injection, chemical flooding, and thermal recovery methods, are improving recovery rates and extending the life of offshore fields.

- Subsea Processing

Subsea processing involves the separation, compression, and transportation of oil and gas directly at the seabed, which reduces the need for large and costly surface facilities. Advances in subsea separators, compressors, and pumps have improved the efficiency of subsea production, enabling oil and gas to be extracted from deeper and more remote fields. Subsea processing technology not only reduces infrastructure costs but also lowers environmental risks by minimizing the number of surface facilities needed.

- Offshore Wind Integration

As part of a growing trend toward sustainable energy, offshore oil platforms are increasingly being integrated with offshore wind power. Hybrid systems that combine oil production with wind energy generation are being developed to reduce the carbon footprint of offshore operations. By harnessing wind energy, offshore oil platforms can reduce reliance on diesel generators, thus cutting down emissions and operating costs. These systems are still in early stages, but are promising for future offshore oil production with a focus on sustainability.

- Autonomous Underwater Vehicles (AUVs)

AUVs are playing a critical role in improving offshore oil production. These unmanned vehicles are used for surveying, inspecting, and maintaining subsea infrastructure. AUVs can operate in hazardous or deep environments where it would be difficult or dangerous for humans to work. They can inspect pipelines, monitor the integrity of subsea equipment, and assist with data collection for reservoir management. The ability to conduct regular, real-time inspections remotely can significantly reduce downtime and maintenance costs.

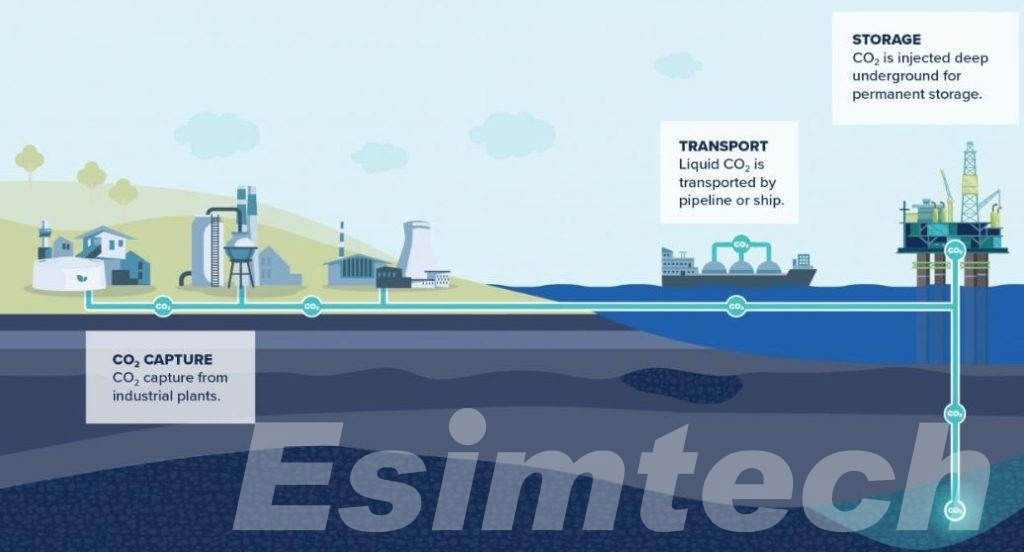

- Carbon Capture and Storage (CCS)

The offshore oil industry is exploring carbon capture and storage (CCS) technologies as a way to reduce the carbon emissions associated with oil production. CCS involves capturing carbon dioxide (CO2) produced during extraction and injecting it into underground geological formations for long-term storage. This technology is seen as critical in helping the industry meet increasing environmental regulations and reduce its carbon footprint. Some offshore oil platforms are already equipped with CCS systems to lower emissions while maintaining production.

- Advanced Safety Systems

In response to the increasing focus on safety, especially after major disasters like the Deepwater Horizon spill, offshore oil platforms are adopting cutting-edge safety technologies. These include blowout preventers (BOPs) with enhanced capabilities, advanced safety alarms, and remote monitoring systems to detect leaks, fires, and other potential hazards in real-time. Additionally, automated emergency response systems are being developed to ensure rapid responses in the event of an accident, improving overall safety and reducing the risk to human lives.

How Simulation Technologies are Used for Optimizing Offshore Oil Production

These simulation technologies are pivotal in improving decision-making, increasing operational efficiency, and enhancing the safety of offshore oil production operations.

| Simulation Technology | Purpose | Key Features | Applications in Offshore Oil Production |

| Reservoir Simulation | Predicting reservoir behavior | Models fluid flow, pressure, and rock properties | Estimating production rates, optimizing recovery methods |

| Flow Assurance Simulation | Managing pipeline flow | Simulates flow dynamics, hydrate formation, and scaling risks | Preventing blockages in pipelines, managing multiphase flow |

| Drilling Simulation | Enhancing drilling efficiency | Models drilling parameters, well trajectory, and equipment performance | Optimizing drill paths, minimizing downtime, improving safety |

| Seismic Simulation | Assessing subsurface formations | Uses seismic data to create 3D/4D models of the subsurface | Identifying new drilling locations, optimizing well placement |

| Dynamic Positioning Simulation | Ensuring stability of offshore platforms | Simulates vessel movement, mooring systems, and environmental conditions | Optimizing platform positioning, minimizing risks from ocean currents and winds |

| Production Optimization Simulation | Maximizing oil output | Simulates production scenarios, reservoir depletion, and equipment failure | Optimizing production rates, managing equipment and maintenance schedules |

| Finite Element Analysis (FEA) | Evaluating structural integrity | Simulates mechanical behaviors of materials under various conditions | Ensuring the safety of rigs, platforms, and subsea equipment |

| Environmental Impact Simulation | Reducing environmental risks | Models oil spills, gas releases, and other environmental hazards | Enhancing safety measures, spill response planning, and risk mitigation |

| Economic Simulation | Cost optimization and risk assessment | Models project economics, cost-benefit analysis, and financial forecasting | Optimizing project investments, managing operational budgets, risk assessment |

Final Thoughts

Offshore oil production remains a vital part of the global energy landscape. While challenges persist, continued innovations in technology and safety measures will be essential in balancing energy security with environmental sustainability, ensuring that offshore drilling remains viable in an evolving energy industry.