What Do You Know about Microbial Enhanced Oil Recovery

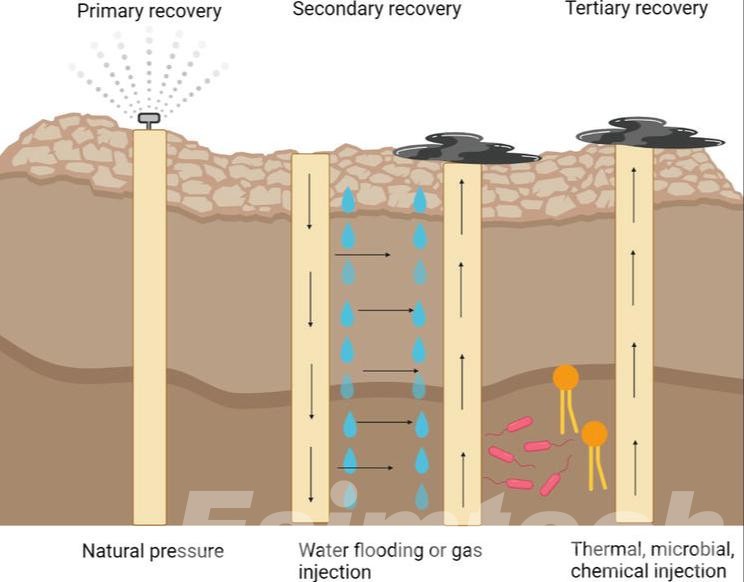

The global demand for energy continues to rise, necessitating innovative solutions to maximize oil recovery from existing reservoirs. Microbial Enhanced Oil Recovery (MEOR) emerges as a promising technology that leverages the power of microorganisms to enhance oil production. By introducing specific microorganisms into oil reservoirs, MEOR can significantly boost oil recovery, making it a valuable tool for the oil and gas industry.

What is Microbial Enhanced Oil Recovery

Microbial enhanced oil recovery is a comprehensive technology that uses the growth and metabolic activities of microorganisms in oil reservoirs or their metabolites to improve crude oil recovery. MEOR technology involves activating native or exogenous microorganisms in oil reservoirs, and producing gas, biosurfactants, organic acids, polymers, etc. through the metabolic activities of microorganisms. These substances can improve reservoir wettability, emulsify crude oil, reduce crude oil viscosity, and reduce flow resistance, thereby improving crude oil recovery.

Importance of MEOR in the Oil Industry

MEOR technology is environmentally friendly and cost-effective, and is especially suitable for mature oil fields where traditional oil recovery methods have limited effectiveness. With the deepening of oil field development, MEOR technology has received more and more attention and research due to its unique advantages.

Recent research and applications have shown that MEOR technology has been tried and successful in different types of oil fields.

- For example, the Yanchang Petroleum Group Research Institute’s endogenous microbial composite oil displacement technology has achieved mature results in the field of endogenous microbial oil recovery technology and has been officially launched at the Ping 77 injection station in the Pingqiao operating area of Xingzichuan Oil Production Plant. It is expected to have significant results and improve oil recovery.

- In addition, microbial technology research in Shengli Oilfield has been going on for nearly 30 years and has made breakthrough progress. Microbial oil flooding technology has developed from a single exogenous microbial flooding to endogenous microbial flooding, microbial fermentation liquid flooding and other technologies, showing that Strong development potential.

The application prospects of MEOR technology are very broad, especially in the context of seeking cost-effective and environmentally friendly enhanced oil recovery technology. As a green and environmentally friendly technology, MEOR’s research and application have received great attention from the industry.

Mechanism of Microbial Enhanced Oil Recovery

The mechanisms by which MEOR enhances oil recovery are complex, involving the interplay of microbial activity and the chemical properties of oil and the reservoir rock. MEOR typically involves injecting specific types of bacteria or other microorganisms into the oil reservoir, where they either directly or indirectly aid in releasing trapped oil. The effectiveness of MEOR depends on the ability of microbes to survive and function under reservoir conditions, including high temperature, pressure, and salinity.

Microbial Processes Involved

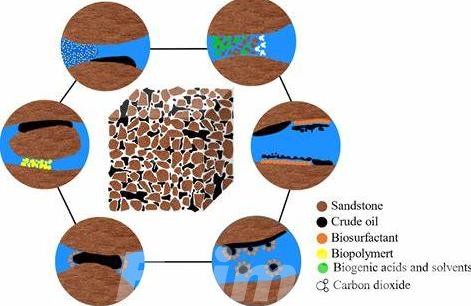

In MEOR, microorganisms are selected for their ability to produce specific metabolic byproducts that influence the physical and chemical properties of the reservoir. Key microbial processes include:

- Biopolymer Production: Certain microorganisms produce biopolymers that increase the viscosity of injected water, which in turn improves its ability to sweep oil through the reservoir. Biopolymers can block high-permeability zones, channeling the water flow into oil-bearing areas of the reservoir. This alteration in flow pattern helps to push trapped oil toward production wells.

- Gas Production: Microorganisms can generate gases such as carbon dioxide (CO₂), methane (CH₄), and hydrogen (H₂) through their metabolic processes. These gases, when produced in situ, build pressure within the reservoir and displace oil from tight rock formations. CO₂, in particular, can dissolve in oil, reducing its viscosity and making it easier to mobilize. This process, often referred to as “microbial gas flooding,” effectively improves the flow of oil and enhances recovery.

- Surfactant Production: Certain bacteria produce biosurfactants that reduce the interfacial tension between oil and water, improving the oil’s ability to move through porous rock formations. Biosurfactants are biodegradable, highly effective, and stable under extreme reservoir conditions, such as high temperature and salinity, making them ideal for MEOR applications. By reducing surface tension, surfactants facilitate the release of oil droplets from the rock matrix, enhancing oil mobility.

- Organic Acid Production: Some microbial species can produce organic acids, which alter the pH levels in the reservoir. Acidic byproducts can react with the mineral components of the rock, improving pore connectivity and creating new channels for oil flow. This process, called “bioplugging,” can modify the reservoir’s permeability in favorable ways, encouraging the movement of trapped oil to production wells.

- Biofilm Formation: Microbial colonies can form biofilms, which are dense aggregations of microorganisms that adhere to reservoir rock surfaces. Biofilms can selectively block certain pathways, diverting fluid flow into less permeable zones where oil is still trapped. The re-routing of water through these blocked channels can help improve oil displacement from zones that were previously inaccessible.

Types of Microorganisms Used

A variety of microorganisms are used in MEOR, each selected based on its unique properties and adaptability to the harsh conditions found in oil reservoirs, such as high temperature, high pressure, and saline environments. Common types include:

- Aerobic and Anaerobic Bacteria: These bacteria can thrive under both oxygen-rich (aerobic) and oxygen-depleted (anaerobic) conditions. Bacillus and Pseudomonas are examples of aerobic bacteria commonly used in MEOR due to their ability to produce biosurfactants and biopolymers. Clostridium, an anaerobic bacterium, is valued for its gas-producing capabilities.

- Thermophilic Microbes: High-temperature reservoirs require thermophilic (heat-loving) microorganisms that can survive in extreme environments. Thermoanaerobacter is an example of a thermophilic bacterium that can generate gas and produce acids, which aid in oil recovery.

- Halophilic Microbes: Saline reservoirs require halophilic (salt-loving) microbes, as high salinity is toxic to many other microorganisms. Halophilic bacteria, such as Halanaerobium, are often used in MEOR due to their resilience and ability to produce byproducts that promote oil mobilization in saline conditions.

Biochemical Interactions

The effectiveness of Microbial Enhanced Oil Recovery is largely influenced by the biochemical interactions between microorganisms and the geological and chemical conditions of the reservoir. These interactions include:

- Surface Tension Reduction: Microorganisms produce biosurfactants that reduce the surface tension between oil and water. This reduction facilitates the flow of oil through the reservoir, particularly in small pore spaces where oil droplets are often trapped due to high surface tension. These biosurfactants are effective even at low concentrations and can endure elevated temperatures and pressures.

- Alterations in pH and Ion Composition: The production of organic acids by microorganisms can change the pH of the reservoir environment. This shift can dissolve minerals in the rock matrix, increasing the reservoir’ s porosity and permeability, which enhances oil movement toward extraction points. Additionally, changes in ion composition can modify the wettability of the rock surface, promoting better oil flow.

- Mineral Dissolution and Rock Alteration: Microbial metabolites, such as organic acids, can interact with minerals in the rock, leading to the breakdown of mineral structures and the widening of pathways for oil flow. These reactions often result in mineral dissolution, facilitating the release of trapped oil from pore spaces.

- Selective Plugging and Flow Diversion: Microbial biofilms play a critical role in forming selective plugs within high-permeability zones. By obstructing these pathways, biofilms redirect water flow into regions still containing oil, thereby improving the efficiency of the water sweep and enabling a more thorough recovery from the reservoir.

Benefits of Microbial Enhanced Oil Recovery

Microbial Enhanced Oil Recovery provides multiple advantages for the oil industry, especially as companies seek more sustainable and cost-effective extraction methods. The key benefits of MEOR include:

- Enhanced Oil Recovery: MEOR can significantly increase the recovery rate from mature reservoirs by mobilizing oil trapped in small pores or isolated pockets. This allows producers to extract more oil from existing fields, extending their productive life and yielding a higher return on investment.

- Cost-Effective Method: Compared to other enhanced oil recovery (EOR) techniques, MEOR is generally less expensive. It reduces the need for costly chemicals and sophisticated equipment required in conventional EOR processes, making it an economically attractive option, particularly for smaller or aging oil fields.

- Environmentally Friendly: MEOR uses naturally occurring microorganisms and reduces the reliance on synthetic chemicals, resulting in a more environmentally benign approach. This minimizes potential soil and water contamination, aligning MEOR with environmental regulations and sustainability goals within the industry.

- Reduced Water and Energy Consumption: MEOR can improve oil flow and extraction without requiring significant amounts of additional water or energy, making it a valuable technique for regions facing water scarcity or high energy costs. This efficiency further reduces the environmental footprint of oil production and conserves vital resources.

- Increased Efficiency Over Time: Microbial processes can continue working over extended periods, gradually improving oil recovery as microbes continue to alter reservoir characteristics. This sustained impact makes MEOR particularly suitable for long-term projects, where gradual yet consistent recovery is desirable.

By enhancing recovery rates, lowering costs, and promoting sustainability, MEOR serves as an innovative solution for maximizing oil extraction from aging fields while meeting industry and environmental standards.

Conclusion

Microbial Enhanced Oil Recovery offers an efficient, cost-effective, and environmentally friendly solution for extracting additional oil from mature fields. By using microorganisms to enhance oil mobility, MEOR not only boosts recovery rates but also reduces environmental impact. As a sustainable alternative to traditional methods, MEOR holds promise for supporting the industry’s evolving needs for efficiency and resource conservation.