What are Well Blowouts and How to Prevent Them

A well blowout is a catastrophic event that occurs when oil, gas, or other fluids are released uncontrollably from a wellbore, typically resulting in significant environmental damage, loss of life, and economic ramifications. This article investigates the causes, consequences, and prevention strategies of well blowouts.

What are the Causes of Well Blowouts

High Reservoir Pressure

The enormous pressure found within hydrocarbon reservoirs is one of the leading causes of blowouts. If the reservoir pressure exceeds the pressure exerted by the drilling mud or fluid used to stabilize the well, a quick and strong expulsion of fluids to the surface can occur.

Formation Fluids

Fluids within distinct rock formations can have variable pressures and compositions when drilled through. If the drilling team encounters a high-pressure formation unexpectedly, it can lead to an influx of fluids into the wellbore, potentially causing a blowout.

Inadequate Well Design

Wells that are poorly built may lack the appropriate safety elements to deal with sudden pressure changes. A well that is not adequately built to contain reservoir pressure can be prone to blowouts.

Faulty Equipment

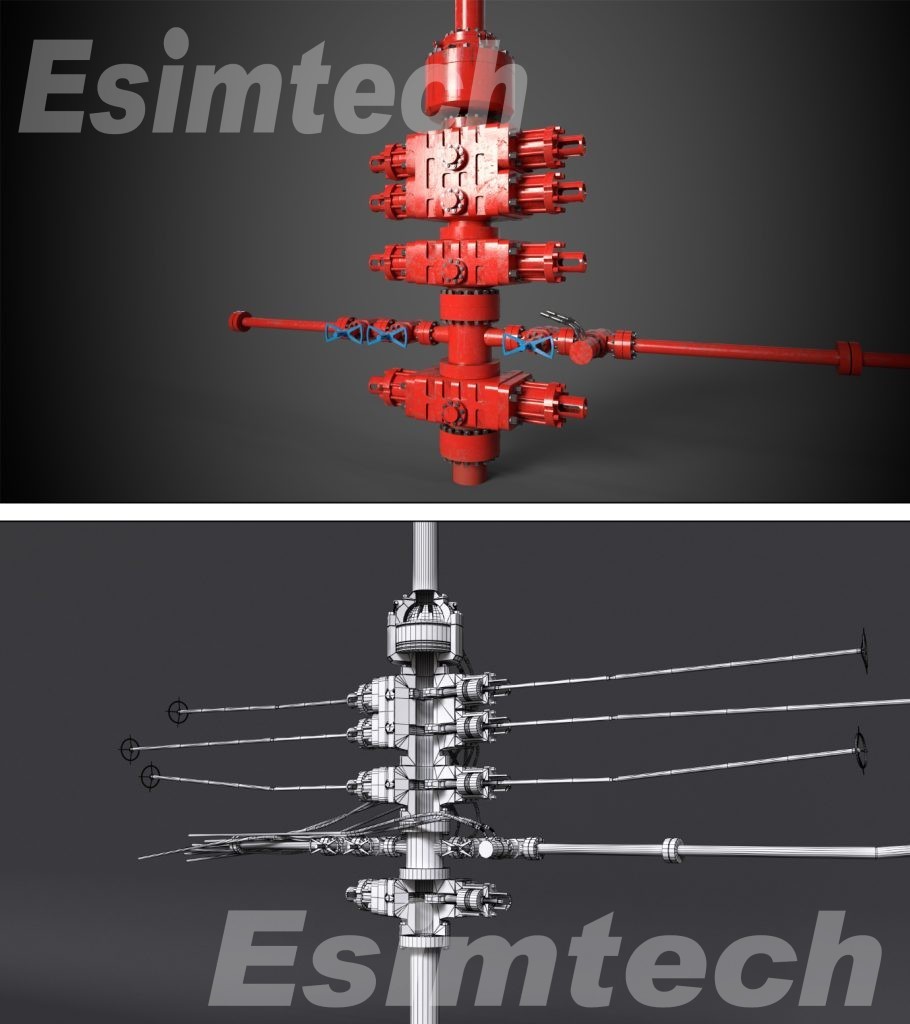

Critical equipment malfunctions or failures, such as blowout preventers (BOPs), can dramatically increase the danger of a blowout. BOPs are intended to close the wellbore in the event of an emergency, and any failure in this equipment can result in the loss of well control.

Drilling Mud Management

Drilling mud is used to support the well, keep the drill bit cool, and control pressure. Improper control of drilling mud parameters such as density and viscosity might lead to an insufficient pressure balance within the wellbore.

Human Error

Mistakes made during drilling operations, such as incorrect pressure calculations, misinterpretation of data, or miscommunication among the drilling team, can contribute to blowouts.

Kick Detection Failure

When reservoir fluids reach the wellbore due to insufficient pressure control, a “kick” occurs. If the kick is not identified early enough or is not managed properly, it might lead to a blowout.

Lack of Training

Inadequate drilling personnel training on well control techniques and blowout prevention measures might result in inappropriate responses in crucial situations.

Natural Factors

Seismic activity or other natural occurrences can cause geological conditions and unanticipated changes in reservoir pressure, resulting in pressure imbalances and blowout risks.

Neglecting Safety Protocols

Cutting corners or violating established safety protocols to save money or drill quicker can raise the probability of a blowout.

Equipment Wear and Tear

Equipment that is old or poorly maintained may be more prone to failure, increasing the danger of a blowout.

What are the Consequences of Well Blowouts

Environmental Impact

Oil spills caused by blowouts can have disastrous consequences for marine and coastal ecosystems. Toxic compounds released into the environment can kill marine life, taint water sources, and disrupt sensitive ecosystems.

Human Health

The vapors from a blowout can be detrimental to human health, causing respiratory problems and other ailments in individuals who live nearby.

Economic Loss

The economic costs of containment and cleanup activities, as well as the loss of potential revenue from the uncontrolled discharge of precious materials, are significant.

Reputation Damage

Following a blowout, the reputation of the oil and gas industry might suffer significantly. Public outcry, media attention, and regulatory inquiries can all damage the reputations of the corporations involved.

What are the Preventive Measures to Prevent Well Blowouts

Preventing well blowouts is a critical goal for the oil and gas sector in order to ensure employee safety, protect the environment, and maintain operational integrity.

Well Design and Construction

Use skilled engineers and geologists to build well constructions that can resist reservoir pressures.

To prevent fluid migration, use strong casing and cementing procedures to isolate and fortify the wellbore.

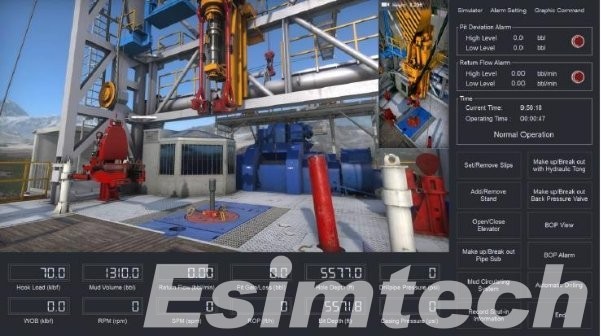

Advanced Technology and Monitoring

Using cutting-edge monitoring equipment and technology, track well conditions, pressures, and temperatures in real time.

Install automated systems capable of detecting pressure anomalies and unexpected changes in drilling conditions.

Blowout Preventers (BOPs)

Install high-quality, well-maintained BOPs as the first line of defense against uncontrolled releases. Inspect, test, and certify these equipment on a regular basis to guarantee proper operation.

Well Control Training

All staff involved in drilling and well operations should receive thorough training. Well control training should be made a requirement of their schooling.

Regular drilling and well control simulations should be conducted to ensure that the team is well-prepared to manage blowout scenarios.

Regulations and Compliance

Follow industry norms and standards established by competent authorities. To prevent blowouts, governments frequently compel enterprises to meet specified safety and operational criteria.

Risk Assessments

Conduct thorough risk assessments before drilling in order to identify potential hazards and plan mitigation strategies accordingly.

Emergency Response Plans

Create thorough emergency response plans outlining step-by-step methods for dealing with blowouts. Make certain that all workers are aware of these strategies.

Safety Culture

Develop a robust safety culture inside the organization in which all employees are empowered to raise concerns and report potential dangers without fear of retaliation.

Regular Inspections and Maintenance

Inspect equipment, machinery, and safety systems on a regular basis to identify and address possible problems before they become serious.

Communication and Collaboration

Maintain open communication and collaboration among all team members, contractors, and service providers to ensure that everyone follows safety guidelines.

Environmental Considerations

Implement methods to reduce the environmental impact of blowouts, such as the use of containment booms, skimmers, and other oil spill-mitigation equipment.

Continuous Improvement

Encourage a culture of continuous improvement in which prior incidents’ lessons are applied to improve preventive measures and response tactics.

Industry Research and Innovation

Invest in R&D to investigate new technologies and approaches that can improve blowout prevention and response capabilities.

Summary

In the oil and gas industry, well blowouts are a real and present hazard. The industry may seek to reduce the occurrence and effects of a well blowout by improved technology, rigorous training, stronger laws, and effective emergency response plans. The need to maintain safe and responsible extraction procedures cannot be stressed as society’s reliance on energy resources continues.