What are the Latest Developments in LNG Shipping

Liquefied Natural Gas (LNG) has emerged as a key player, with shipping being a crucial link in its supply chain. Recent advancements in LNG shipping have focused on improving efficiency, reducing emissions, and enhancing infrastructure, making LNG transportation more sustainable and scalable to meet rising demand. This article highlights the latest developments in LNG shipping that are driving innovation and efficiency in natural gas industry.

Main Traditional Methods Used in LNG Shipping

This chart summarizes the various traditional methods used in LNG shipping, emphasizing their structural approaches, benefits, and associated challenges.

| Method | Description | Advantages | Challenges |

| Moss Spherical Tanks | Uses spherical tanks to store LNG. The tanks are independent and robust, often made from aluminum or 9% nickel steel. | Highly resistant to sloshing; Proven design with long operational history. | Bulky design limits cargo capacity; Higher construction cost. |

| Membrane Tanks | Thin membranes (Invar or stainless steel) are used inside the hull to contain LNG, supported by insulation systems. | More efficient use of space, allowing greater cargo capacity. | Susceptible to sloshing effects; Requires specialized insulation. |

| Pressurized LNG Tanks | LNG is stored under pressure in cryogenic tanks, reducing the need for external cooling systems. | Simple system with minimal cooling requirements. | Pressure limits restrict cargo size; Not suitable for long-distance shipping. |

| Prismatic Tanks | Prismatic-shaped tanks maximize hull space, typically integrated into the ship’s structure. | Maximizes cargo capacity by using available space more effectively. | Higher risk of structural stress; More complex construction required. |

| LNG Barges | LNG is transported on barges designed for coastal or riverine operations, providing flexibility for small-scale distribution. | Cost-effective for short distances; Suitable for shallow waters. | Limited to regional transport; Vulnerable to weather conditions. |

| LNG Shuttle Vessels | These vessels transport LNG from offshore liquefaction facilities to LNG carriers, reducing dependence on pipelines. | Flexibility in offshore LNG transfer; Can access remote gas fields. | High operational costs; Potential delays due to weather. |

| Conventional LNG Carriers | These are typical LNG vessels that use large tanks, either membrane or spherical, to transport LNG between countries. | Proven and reliable technology; Available infrastructure globally. | High operating costs; Limited adaptability to smaller terminals. |

Key Developments and Innovations in LNG Shipping

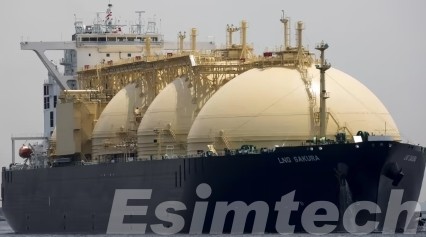

Larger, More Efficient LNG Carriers

One of the most prominent trends in LNG shipping is the development of larger vessels capable of carrying more gas per voyage. The newest generation of LNG carriers, such as the Q-Max and Q-Flex ships, can transport up to 266,000 cubic meters of LNG, making them the largest LNG carriers in the world. These vessels reduce per-unit transportation costs and increase operational efficiency.

Moreover, newer carriers are adopting dual-fuel propulsion systems, allowing them to run on both LNG and conventional marine fuel. This reduces fuel consumption, emissions, and overall operational costs, contributing to a more sustainable shipping process.

Improvements in LNG Storage and Containment Systems

Another critical area of innovation in LNG shipping is in containment systems. Traditional membrane containment systems have been enhanced to reduce boil-off gas (BOG), which occurs when LNG evaporates during transport. Advanced insulation technologies and reliquefaction systems are being incorporated into LNG carriers to minimize BOG losses, ensuring more efficient transport and reducing environmental impact.

The adoption of Mark III Flex and NO96 containment systems has become standard in modern vessels. These designs offer superior thermal performance, allowing for safer and more efficient storage of LNG while in transit.

Autonomous Shipping and Digitalization

The LNG shipping industry is embracing autonomous technologies to enhance safety and operational efficiency. Autonomous LNG carriers are in development, equipped with advanced sensors, AI-driven navigation systems, and real-time data analytics to optimize route planning and fuel usage. These innovations are designed to reduce human error, improve operational efficiency, and enhance safety, particularly in challenging oceanic environments.

Digitalization also plays a pivotal role in the monitoring of LNG cargo conditions. Advanced digital systems allow for real-time tracking of temperatures, pressures, and tank conditions, improving both the safety and efficiency of LNG transport.

Environmental Regulations and Cleaner Shipping

The global push towards reducing carbon emissions has led to the development of greener technologies in the LNG shipping sector. One of the most significant changes has been the shift towards LNG as a marine fuel itself, replacing heavy fuel oil. This transition reduces greenhouse gas emissions and other pollutants, such as sulfur oxides (SOx) and nitrogen oxides (NOx).

The International Maritime Organization’s IMO 2020 regulations, which limit sulfur content in marine fuels, have driven a sharp increase in the adoption of LNG-fueled vessels. Additionally, efforts are being made to design more energy-efficient LNG carriers, including the integration of air lubrication systems, improved hull designs, and the use of wind-assisted propulsion to reduce fuel consumption.

Expansion of Global LNG Infrastructure

To accommodate the increasing demand for LNG, there has been a rapid expansion of LNG export and import terminals around the world. Floating Storage Regasification Units (FSRUs) are becoming more prevalent, providing flexible and cost-effective solutions for countries looking to import LNG without the need for traditional onshore terminals.

FSRUs offer several advantages, including reduced construction times, lower costs, and the ability to relocate to different regions as market demands shift. These developments are crucial for emerging economies looking to diversify their energy portfolios with cleaner energy sources.

LNG Bunkering

With the rise of LNG as a marine fuel, LNG bunkering infrastructure has become a significant focus of development. Ports around the world are investing in facilities that can refuel LNG-powered ships, ensuring they have the fuel supply needed to complete long-haul journeys. Major ports in Europe, Asia, and North America have already established LNG bunkering services, and the global network continues to grow.

Market Dynamics and Strategic Alliances

In response to growing global energy demand, the LNG shipping industry is experiencing a shift in market dynamics. Strategic alliances between shipping companies, energy producers, and terminal operators are becoming more common, enabling more efficient global LNG supply chains.

Additionally, there has been a notable increase in long-term charter agreements and joint ventures, allowing shipping companies to secure stable revenues and mitigate market volatility. These partnerships are essential for ensuring the long-term sustainability of LNG transportation infrastructure.

Hydrogen and Ammonia Integration

As the world transitions to more sustainable energy solutions, LNG shipping could evolve to transport hydrogen and ammonia—two fuels that have the potential to revolutionize clean energy. LNG carriers could be modified to transport these new fuels, providing a pathway for existing infrastructure to adapt to future energy needs. Some companies are already exploring the feasibility of using LNG ships for hydrogen transportation, potentially paving the way for a cleaner and more diversified energy shipping market.

How Simulation Technology is Contributing to the Development in LNG Shipping

From ship design and operational efficiency to crew training and risk mitigation, simulation technology is a powerful tool enabling advancements in LNG shipping.

Design Optimization for LNG Carriers

One of the most significant contributions of simulation technology is in the design phase of LNG carriers. Engineers use computational fluid dynamics (CFD) simulations to analyze and optimize ship hull designs, improving hydrodynamics to reduce fuel consumption and enhance operational efficiency. These simulations allow for testing various hull shapes and propulsion systems without the cost of physical prototypes.

Additionally, LNG tank designs can be simulated to ensure the safe and efficient storage of liquefied gas. Thermal simulations of the containment systems help in optimizing insulation materials and reducing boil-off gas (BOG) during transport. By fine-tuning ship designs through simulation, the LNG industry can create more fuel-efficient and environmentally friendly carriers.

Enhanced Crew Training

Operating an LNG carrier requires highly skilled personnel who can handle the complexities of the cargo and the ship’s systems. Simulation-based training provides crews with realistic, hands-on experiences without the risks involved in real-life operations. Advanced ship simulators replicate the actual conditions of LNG transportation, including navigation, cargo handling, and emergency response scenarios.

These simulators enable crews to practice responding to critical situations such as gas leaks, fire hazards, or system malfunctions, ensuring they are well-prepared for real-life challenges. By providing this safe and controlled training environment, simulation technology helps improve safety standards across the LNG shipping industry.

Operational Efficiency and Route Optimization

Simulations are also used to optimize operational procedures and voyage planning for LNG ships. Advanced algorithms can simulate different gas shipping routes, taking into account factors such as weather patterns, ocean currents, and port conditions to determine the most fuel-efficient and cost-effective routes.

In addition, cargo management simulations help ensure that the LNG is stored and transported in the most efficient manner, reducing boil-off gas and maintaining cargo quality. By optimizing routes and operations through simulation, shipping companies can significantly reduce fuel consumption, minimize delays, and lower operating costs.

Safety and Risk Assessment

Safety is a top priority in LNG shipping, given the volatility of liquefied natural gas and the complex nature of the ships that transport it. Simulation technology plays a vital role in risk assessment and accident prevention. Using emergency scenario simulations, ship designers and operators can identify potential risks and weaknesses in the vessel’s systems and develop strategies to mitigate these risks.

Simulation tools are also used to model the behavior of LNG in various situations, such as leaks, spills, or explosions, enabling engineers to design more robust safety systems. Evacuation drills and emergency response simulations ensure that crews are prepared for the worst-case scenarios, ultimately contributing to safer LNG shipping operations.

Environmental Impact and Emission Reduction

Simulation technology is helping the LNG shipping industry meet stringent environmental regulations by optimizing ship designs and operations to minimize emissions. Emission simulations allow for testing various propulsion and energy systems, such as dual-fuel engines and LNG-fueled vessels, to reduce greenhouse gas emissions, nitrogen oxides (NOx), and sulfur oxides (SOx).

By simulating fuel efficiency and emission performance under different operating conditions, companies can better meet the environmental standards set by bodies like the International Maritime Organization (IMO). These simulations help the industry transition to cleaner technologies, such as wind-assisted propulsion or battery integration, while maintaining operational efficiency.

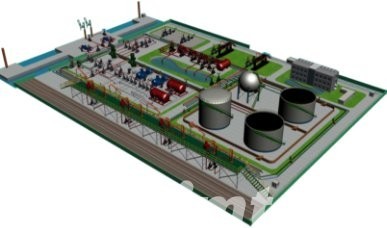

Port and Terminal Simulation

Efficient LNG shipping also depends on the infrastructure at export and import terminals. Port and terminal simulations enable planners to optimize the layout and operations of LNG loading and unloading facilities. These simulations can model ship traffic, port congestion, and cargo transfer processes, ensuring that terminals can handle large LNG carriers efficiently without causing delays.

By simulating LNG storage, regasification, and bunkering operations, companies can optimize terminal capacity and reduce the risk of bottlenecks in the supply chain. This is especially critical as the demand for LNG grows, requiring faster and more efficient turnaround times at ports.

Maintenance and Predictive Analytics

Simulation technology also supports predictive maintenance for LNG carriers. By simulating the wear and tear of key ship components, shipping companies can develop maintenance schedules that reduce downtime and improve the longevity of equipment. Digital twin technology, which creates a virtual replica of the ship, enables real-time monitoring and predictive analytics to identify potential system failures before they occur.

This data-driven approach to maintenance ensures that ships operate more efficiently and with fewer unexpected breakdowns, improving both safety and profitability in LNG shipping.

To sum up, the LNG shipping industry is undergoing a transformative phase as new technologies, environmental regulations, and market forces reshape the way natural gas is transported across the globe. With innovations in ship design, storage systems, autonomous technologies, and infrastructure, LNG shipping is set to become even more efficient, environmentally friendly, and critical to meeting global energy needs.

simulation technology plays an increasingly important role in driving innovations and ensuring the efficiency, safety, and sustainability of the LNG shipping sector. Whether optimizing routes, training crews, or enhancing safety systems, oil and gas simulation tools provide critical insights that are helping the industry meet the growing demand for cleaner energy transportation.