What are the Differences Between Cased-Hole and Open-Hole Logging

When it comes to oil and gas exploration, well logging is a crucial step in understanding the subsurface geology and evaluating the potential of a reservoir. Two primary methods of well logging are cased-hole and open-hole logging. Both techniques are essential for acquiring detailed information about the well, but they serve different purposes and are applied at different stages of the drilling process.

What is Cased-Hole Logging

Cased hole logging is a commonly used technology in petroleum engineering, mainly used to evaluate and monitor the status of casing, the physical characteristics of the formation, and the flow of oil and gas. This technology can provide engineers with key information about well performance, helping them better understand and manage reservoirs.

Cased hole logging can not only help determine the integrity and possible damage of the casing, but also evaluate the physical characteristics of the formation, such as porosity, permeability, and water content. This is very important for both daily operations and long-term planning of oil fields. By analyzing this data, engineers can adjust oil field development strategies, optimize reservoir management, and improve oil and gas recovery.

What is Open-Hole Logging

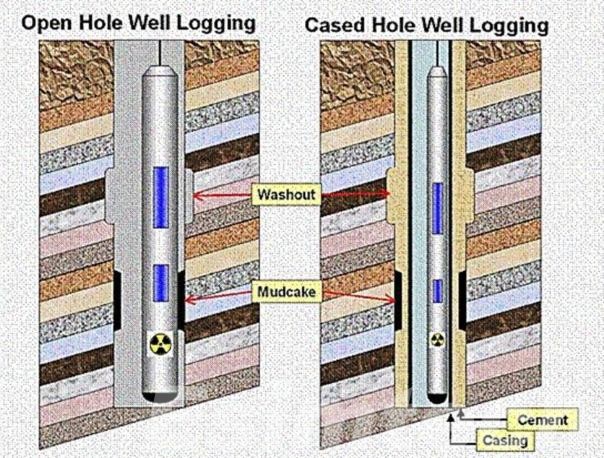

Open hole logging is a logging operation carried out in an open hole without casing. It is mainly used to obtain physical parameters of the downhole formation, such as resistivity, acoustic velocity, natural potential, etc., to evaluate the reservoir performance and fluid properties of the formation. These data are crucial for the exploration and development of oil and gas reservoirs and can provide decision-making basis for geologists and engineers.

Open hole logging technology includes multiple methods such as electrical logging, acoustic logging, and nuclear magnetic resonance logging. Each method has its specific measurement principle and application range.

1. Nuclear magnetic resonance logging technology

Nuclear magnetic resonance logging is an advanced logging technology that can directly measure the volume characteristics of free fluid in the reservoir and has unique advantages. It uses the magnetism of hydrogen nuclei and their interaction with an external magnetic field to detect the formation pore characteristics and fluid characteristics by measuring the nuclear magnetic resonance relaxation characteristics of hydrogen nuclei in the formation pore fluid. Nuclear magnetic resonance logging technology provides key technical support in oil and gas exploration and can accurately reveal the porosity, permeability and fluid type of the formation.

2. Application of Nuclear Magnetic Resonance Logging Technology

In practical applications, nuclear magnetic resonance logging technology can help geologists accurately identify oil and gas layers, especially in complex formation environments, such as the evaluation of shale oil reservoirs, showing great potential. For example, in the productivity analysis and sweet spot evaluation of shale oil horizontal wells in the Lucaogou Formation in the Jimusar Depression, nuclear magnetic resonance logging technology established a movable oil volume evaluation model through the fine characterization of the distribution of different types of fluids, clarified the control factors of horizontal well productivity, and provided a scientific basis for the fine development of shale oil.

Cased-Hole Logging vs. Open-Hole Logging

Cased hole logging and open hole logging are two common logging technologies in the oil industry. They each have different application scenarios and technical characteristics. This analysis will compare and analyze these technologies in detail from multiple perspectives.

Cased Well Logging

Cased well logging is mainly used for oil or gas wells that have completed preliminary development or are in production. The main purpose of cased well logging is to evaluate the status of the casing that has been installed, check whether there is damage or corrosion, and re-evaluate the production layer.

Technical Features:

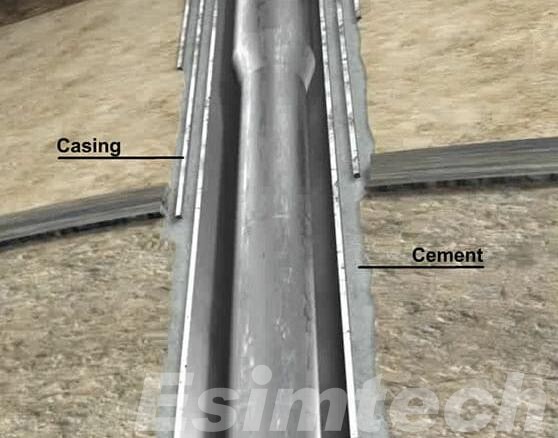

- Cementing quality logging: used to detect the quality of cementing, that is, the bonding between the casing and the cement sheath.

- Production logging: mainly includes well diameter logging, fluid logging, etc., which are used to monitor the casing conditions and fluid properties in the production well.

- Perforation positioning: use methods such as gamma curves to locate the target layer for perforation operations.

Open hole logging

Open hole logging is usually used in wells in the oil and gas exploration stage.

Technical Features:

- Comprehensive geological evaluation: In a well without casing, a comprehensive evaluation of the formation is directly carried out, including but not limited to the rock properties, pore structure, permeability, etc. of the formation.

- Multiple logging items: including gamma, borehole diameter, natural potential, sonic wave, neutron, density and other logging items, which can provide a more comprehensive understanding of the formation information.

| Features | Cased well logging | Open hole logging |

| Operation phase | Development or production stage | Exploration stage |

| Main purpose | Assess casing status and re-evaluation of production layers | Comprehensive evaluation of the formation |

| Logging items | Cementing quality, production logging, etc. | Gamma, well diameter, natural potential, acoustic wave, etc. |

| Data type | Mainly for cased wells | Mainly for uncased wells |

Applications of Cased-Hole and Open-Hole Logging

Both cased-hole and open-hole logging are vital in the oil and gas industry, but they are used at different stages of well development and for different purposes. Understanding when and why each type of logging is used can help ensure the well is as productive and safe as possible.

Applications of Cased-Hole Logging

Cased-hole logging is done after the well has been drilled and the metal casing (a protective pipe) is placed inside the well. This logging method is mostly used to check the well’s health and ensure everything is working as it should.

- Production Evaluation: One of the main uses of cased-hole logging is to assess how well the well is producing oil or gas. By measuring the flow of hydrocarbons (oil and gas) through the perforations in the casing, engineers can determine which zones of the well are producing the most and decide if any changes are needed to improve output.

- Cement Evaluation: After the casing is installed, cement is pumped around it to secure it in place and prevent fluids from moving between different layers of rock. Cased-hole logging tools can be used to evaluate the quality of this cement job. If there are gaps or weak spots, fluids might leak, which can lead to environmental problems or loss of valuable resources. This evaluation ensures that the cement is solid and properly sealed.

Reservoir Monitoring: Over time, the conditions in a reservoir can change as oil and gas are extracted. Cased-hole logging can be used to monitor these changes and provide ongoing data about the reservoir’s performance. This helps in making informed decisions about future drilling or production strategies, ensuring the well continues to operate efficiently.

Applications of Open-Hole Logging

Open-hole logging is performed right after the well is drilled, but before the casing is put in. Since the wellbore is still open and exposed, this type of logging provides detailed information about the rock formations and fluids (like oil, gas, and water) that surround the well.

- Reservoir Evaluation: Open-hole logging tools measure properties like the type of rock, its porosity (how much space there is within the rock), and its permeability (how easily fluids can flow through the rock). By analyzing these properties, engineers can determine whether the reservoir contains enough oil or gas to be worth extracting.

- Formation Evaluation: This type of logging also helps in understanding the formation or layers of rock through which the well passes. It identifies the thickness of these layers, the types of fluids present, and the pressures within them. This information is critical for deciding how to complete the well to maximize production and avoid issues like water intrusion or blowouts.

- Well Design Optimization: The data gathered from open-hole logging is used to design the casing and other completion tools for the well. Knowing the specific conditions of the rock and fluids helps in selecting the right materials and techniques to ensure the well operates safely and efficiently throughout its life.

Simulation Technology for Well Logging

Simulation technology brings sophisticated tools and methods that help engineers and geologists make better decisions. At its core, simulation involves creating digital models that mimic real-world conditions. For well logging, this means using computer programs to simulate what happens inside a well and its surrounding rock formations based on the data collected from logging.

How Simulation Technology Works

- Data Integration: Simulation starts with data from well logs, which provide information about the wellbore, rock formations, and fluids. This data is combined with other information like seismic surveys and geological studies.

- Creating Digital Models: Using this data, engineers create detailed digital models of the well and its environment. These models represent the wellbore, surrounding rock layers, and fluid reservoirs.

- Running Simulations: Engineers can run simulations to see how the well and reservoir might behave under various conditions. For example, they can model how changing the pressure or injecting certain fluids might affect oil or gas production.

- Analyzing Results: The simulation provides insights into potential outcomes, helping engineers understand how different scenarios might impact well performance. This helps in identifying the best strategies for drilling, completing, and managing the well.

Well Logging Simulation in Real-World Applications

- Well Design: Engineers use simulations to design wells that maximize production while minimizing risks. For example, they can test different casing designs or completion techniques to find the most effective solution.

- Production Optimization: Simulations help in understanding how different methods of extracting oil or gas can impact production rates and efficiency. This helps in fine-tuning production techniques to achieve the best results.

- Reservoir Management: By simulating how fluids move through the reservoir, engineers can develop better strategies for managing and enhancing hydrocarbon recovery.

In summary, simulation technology provides a powerful tool for improving well logging practices. By creating virtual models and running simulations, engineers can gain deeper insights into well behavior, optimize drilling and production processes, and make more informed decisions. This technology not only enhances accuracy and efficiency but also helps in managing risks and reducing costs, making it a vital component of modern oil and gas operations.