What are Gas Production Simulators: Key Capabilities, Advantages and Impacts on the Energy Industry

Natural resource extraction and management are crucial to providing a sustainable and stable energy supply. Gas production simulators have evolved as significant tools in recent years, allowing energy businesses to optimize their gas extraction operations, improve decision-making, and boost overall operational efficiency. This article delves into what are gas production simulators, their essential capabilities and benefits, and their significant impact on the energy industry.

Why Gas Production Simulators are Important

Advanced computer models that simulate the behavior of gas reservoirs and accompanying production processes are known as a gas production simulator. To model and anticipate gas flow rates, pressure variations, and other vital factors, these simulators employ complicated algorithms based on geological, engineering, and mathematical principles. By creating a digital representation of a gas field, these simulators allow energy companies to perform virtual experiments, evaluate multiple scenarios, and gain valuable insights into their production operation.

What are the Key Capabilities and Advantages of the Gas Production Simulators

Reservoir Modeling

Simulators for gas production accurately portray the complicated geological formations beneath the Earth’s surface, including details like porosity, permeability, and fluid saturation. This enables engineers to view and study the behavior of the gas reservoir under various situations, optimizing well placement, anticipating production behavior, and more correctly calculating reserves.

Fluid Flow Simulation

Fluid dynamics principles are used by simulators to recreate the flow of gas within the reservoir and throughout the production system. They take pressure differentials, fluid characteristics, and wellbore dynamics into account, allowing engineers to anticipate production rates and improve extraction tactics. Companies can find the most effective manufacturing procedures, reduce output decline, and build recovery strategies by simulating various scenarios.

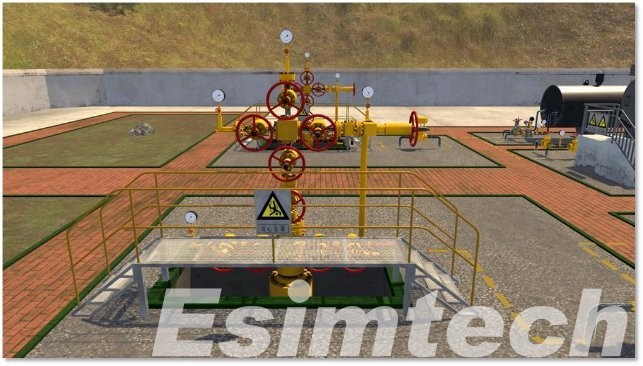

Wellbore and Surface Equipment Modeling

Gas production Simulators include comprehensive models of wellbores, completion procedures, and surface facilities(https://www.esimtech.com/detailed-guide-to-the-oil-and-gas-production-and-transportation-simulation-training-system.html). This allows engineers to evaluate the effect of various well designs, equipment combinations, and production techniques on overall performance. Companies can improve production, cut costs, and reduce equipment failures by improving wellbore design.

Scenario Analysis

Engineers can use simulators to develop and analyze several scenarios in order to examine the probable repercussions of various operational actions. Companies can determine the most effective techniques to optimize output while minimizing expenses by adjusting parameters like as production rates, well spacing, and reservoir management tactics. Scenario analysis assists businesses in assessing the impact of uncertainty and making educated decisions that improve operational efficiency.

Risk Mitigation

Simulators assist businesses in identifying potential risks and uncertainties in their operations. Companies can examine the impact of elements such as reservoir heterogeneity, well interference, and equipment failures by simulating various production scenarios. This enables them to devise risk-mitigation measures and reduce possible losses. Companies can use gas production simulator to identify potential hazards and vulnerabilities and develop methods to mitigate their impact.

Cost Optimization

Companies can use gas production simulators to uncover cost-cutting options by examining the efficiency of their production processes. Organizations can cut capital expenditures, increase operational efficiency, and reduce production costs by optimizing well placement, equipment design, and operating parameters. Simulators provide insights into the most cost-effective manufacturing processes, helping businesses to better manage resources.

Environmental Sustainability

Gas production simulator helps to ensure environmental sustainability in the face of mounting worries about climate change. Companies can cut greenhouse gas emissions, lower their environmental footprint, and ensure responsible resource management through improving extraction methods. Engineers can use simulations to assess the environmental impact of various manufacturing scenarios and develop methods that correspond with sustainability goals.

What are the Impacts of the Gas Production Simulator on the Energy Industry

Reducing Exploration Risk

Gas production simulators are critical in lowering exploration risk. Companies can reduce risk and focus their efforts on the most viable opportunities by studying geological data, simulating different exploration scenarios, and appraising the potential of unexplored areas. This results in more efficient exploration while also lowering the cost and uncertainty associated with exploratory efforts.

Enhancing Collaboration

Gas production simulations make it easier for interdisciplinary teams to collaborate. Geologists, reservoir engineers, production engineers, and geophysicists can all contribute their knowledge to simulation models, enabling cross-functional collaboration and resulting in more thorough and robust decision-making. Simulators give a collaborative environment for teams to collaborate, share insights, and optimize production techniques.

Talent Development

The use of gas production simulator has increased the requirement for highly skilled people who are knowledgeable about reservoir engineering and computational approaches. As a result, increasing investment in training and talent development initiatives has occurred in the industry. Simulators require individuals who can operate the software efficiently, evaluate results, and make informed judgments. This has led to the growth of a specialized workforce and the development of skill sets that are valuable in the energy industry.

Summary

Gas production simulators are becoming increasingly important in satisfying the world’s expanding energy demands while guaranteeing responsible resource management and environmental sustainability. This kind of oil and gas simulator promotes innovation, improving collaboration, and advancing the industry toward a more sustainable and efficient future.