What are Effective Pipeline Leak Detection Methods

Pipelines play a critical role in transporting crude oil, natural gas, and refined products over long distances. However, maintaining the integrity of these pipelines is essential to prevent leaks, which can result in environmental disasters, safety risks, significant financial losses, etc. Detecting pipeline leaks early is vital to minimizing damage and ensuring operational efficiency. This article explores the various pipeline leak detection methods used in the oil and gas industry and the technological advancements that are transforming this critical process.

Importance of Leak Detection in Oil and Gas Pipelines

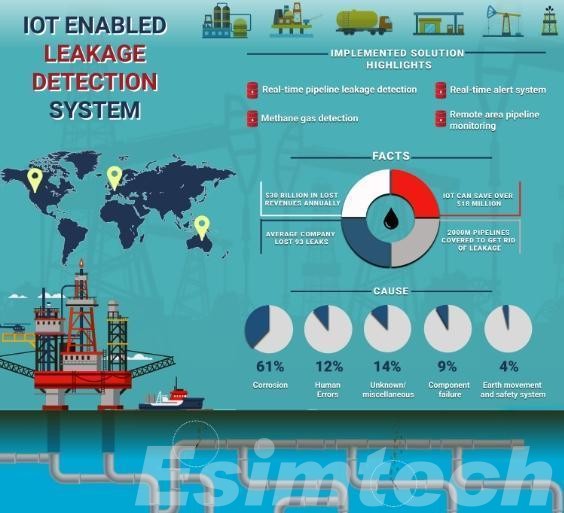

Pipelines, due to their size and the harsh environments they traverse, are prone to leaks caused by factors such as corrosion, mechanical failure, third-party damage, or natural disasters.

Undetected leaks can lead to:

- Environmental Damage: Leaks can pollute soil, water sources, and ecosystems, leading to costly cleanup efforts and lasting ecological impacts.

- Health and Safety Risks: Escaped oil or gas poses significant health hazards, including fire and explosion risks.

- Financial Losses: Leaks lead to product losses, increased operational costs, and potential fines due to non-compliance with environmental regulations.

- Regulatory Compliance: Governments and environmental bodies enforce strict regulations on leak detection. Non-compliance can result in hefty penalties and damage to a company’s reputation.

Effective pipeline leak detection systems ensure operators can quickly identify and respond to leaks, reducing their impact.

Types of Pipeline Leak Detection Methods

The oil and gas industry employs various leak detection technologies, which can be classified into internal and external methods.

1. Internal Pipeline Leak Detection Systems

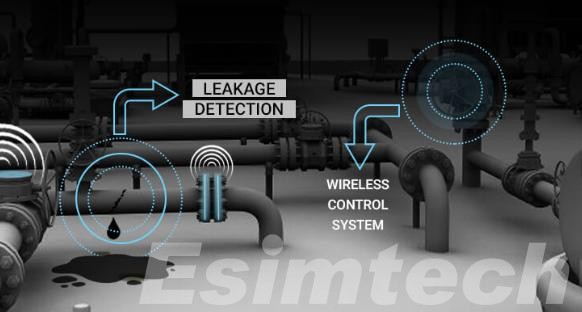

Internal leak detection systems monitor the flow of oil or gas within the pipeline to identify anomalies that suggest a leak. These methods include:

- Pressure Monitoring: This system detects pressure drops along the pipeline that may indicate a leak. If pressure falls below a certain threshold, the system triggers an alarm.

- Flow Monitoring: This method compares the volume of product entering and leaving a section of the pipeline. A discrepancy in flow rates signals a possible leak.

- Mass Balance Systems: Mass balance leak detection involves monitoring the total mass of product at the inlet and outlet of the pipeline. If a significant difference occurs, it suggests a leak. This method is widely used because of its relatively low cost and ability to detect leaks over large distances.

- Real-Time Transient Model (RTTM): RTTM uses mathematical models to simulate the behavior of fluids in the pipeline. By continuously comparing real-time data to the model’s predictions, the system can detect abnormal conditions, such as leaks or blockages.

2. External Pipeline Leak Detection Systems

External systems use sensors or monitoring devices outside the pipeline to detect leaks. Common external leak detection methods include:

- Acoustic Sensors: These sensors listen for the acoustic signature of a leak. The sound generated by escaping oil or gas can be picked up by microphones placed along the pipeline. Advanced systems can differentiate between normal pipeline sounds and those indicating a leak.

- Fiber Optic Sensing: Fiber optic cables installed along the pipeline detect temperature changes or strain anomalies. Leaks often cause temperature fluctuations or structural vibrations in the surrounding area, which the fiber optic sensors can identify. This method is particularly useful for detecting small leaks and monitoring pipelines in remote locations.

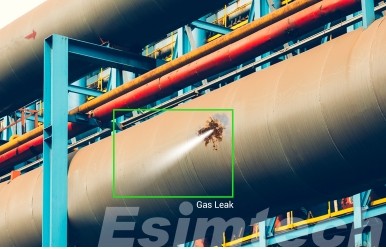

- Thermal Imaging: Thermal cameras mounted on drones or aerial vehicles can detect temperature changes along the pipeline. Leaking gas or oil creates temperature variations on the ground, which can be captured by thermal sensors.

- Hydrocarbon Sensing Cables: These specialized cables are designed to detect the presence of hydrocarbons. When hydrocarbons from a leak come into contact with the cable, it triggers an alarm, enabling operators to pinpoint the leak’s location.

- Satellite Monitoring: Satellites equipped with advanced imaging technology can monitor pipeline routes for signs of leaks, such as vegetation changes, soil movement, or surface anomalies. While still in development, satellite technology holds promise for monitoring large and remote pipeline networks.

Challenges in Pipeline Leak Detection

This chart outlines the primary challenges faced in pipeline leak detection, their impacts, and potential strategies to mitigate these issues.

| Challenge | Description | Impact | Mitigation Strategies |

| False Positives | Leak detection systems often trigger alarms for non-leak events, such as operational changes or maintenance. | 1. Wastes time and resources on unnecessary inspections 2. Reduces trust in the detection system | 1. Improved data filtering 2. Machine learning for pattern recognition |

| Remote and Inaccessible Locations | Pipelines often traverse difficult-to-access regions, making physical inspections challenging. | 1. Delays in detecting and repairing leaks 2. Higher risk of environmental damage in sensitive areas | 1. Use of drones and satellite surveillance 2. IoT-enabled remote monitoring systems |

| Small Leak Detection Sensitivity | Detection systems may struggle to detect small leaks that do not produce significant pressure or flow changes. | 1. Prolonged undetected leaks 2. Potential long-term environmental damage | 1. Deploy more sensitive technologies like fiber optics or acoustic sensors |

| Harsh Environmental Conditions | Extreme temperatures, high pressure, or underwater conditions can affect the accuracy of detection technologies. | 1. Reduced effectiveness of sensors 2. Higher risk of sensor failure | 1. Ruggedized sensor designs 2. Real-time system recalibration |

| Data Overload | Massive amounts of data from sensors can overwhelm operators, making it hard to pinpoint genuine leaks. | 1. Slower decision-making 2. Increased risk of overlooking critical events | 1. Cloud-based data processing 2. AI and machine learning for data analysis |

| Pipeline Aging and Corrosion | Older pipelines are more prone to leaks due to corrosion, cracking, and mechanical wear. | 1. Increased frequency of leaks 2. Higher maintenance costs | 1. Predictive maintenance through simulation 2. Regular integrity assessments |

| Cross-Interference in Detection Systems | Various pipeline systems (e.g., gas, oil, water) may interfere with each other’s detection methods. | 1. Misidentification of leak sources 2. False alarms | 1. Calibrating systems to specific substances 2. Isolated detection zones |

| Regulatory and Compliance Issues | Complex regulations across different regions may hinder the implementation of certain leak detection technologies. | 1. Delays in deploying new technology 2. Risk of penalties or fines for non-compliance | 1. Regular updates on regional regulations 2. Collaboration with regulatory bodies |

| Cost of Implementation | Advanced leak detection technologies can be costly to implement, particularly for long-distance pipelines. | 1. Financial strain on operators 2. Delayed technology adoption | 1. Cost-benefit analysis 2. Phased implementation strategies |

| Cybersecurity Risks | Digital leak detection systems are vulnerable to cyberattacks that could manipulate data or shut down systems. | 1. Risk of undetected leaks 2. Potential for false alarms or system shutdowns | 1. Implement strong cybersecurity protocols 2. Regular system audits and updates |

Technological Advancements in Pipeline Leak Detection

1. Artificial Intelligence (AI) and Machine Learning (ML)

Artificial Intelligence (AI) and Machine Learning (ML) are revolutionizing pipeline leak detection by enhancing data analysis and improving system accuracy. AI and ML algorithms are able to analyze vast amounts of real-time sensor data from pipeline monitoring systems, identifying patterns that may indicate leaks.

- Predictive Analytics: AI can predict potential pipeline failures by analyzing historical and real-time data, detecting early signs of leaks or mechanical wear before they escalate.

- False Alarm Reduction: ML systems learn to differentiate between normal pipeline operations and leak indicators, reducing the number of false alarms and allowing operators to focus on genuine issues.

- Autonomous Detection: AI systems can autonomously detect leaks and trigger alerts, enabling faster response times without the need for constant human monitoring.

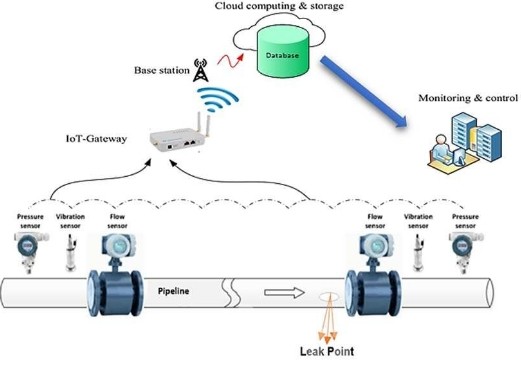

2. Internet of Things (IoT)

IoT technology has enabled the deployment of a vast network of sensors along pipelines, providing continuous and real-time monitoring. These sensors collect data such as pressure, temperature, and flow rates, which can be analyzed to detect anomalies that indicate leaks.

- Real-Time Monitoring: IoT sensors provide continuous feedback on pipeline conditions, allowing operators to detect even minor deviations from normal operations that may signal a leak.

- Remote Monitoring: IoT technology allows operators to monitor pipelines in remote locations or harsh environments, reducing the need for manual inspections.

- Predictive Maintenance: By collecting detailed data over time, IoT-enabled systems can predict maintenance needs, preventing leaks before they occur.

3. Drone and Aerial Surveillance

Drones and aerial surveillance technologies, including thermal imaging and hyperspectral cameras, are becoming increasingly popular for pipeline monitoring, especially for pipelines that traverse remote or difficult-to-access regions.

- Thermal Imaging: Leaking oil or gas often causes temperature changes on the ground or in the surrounding environment. Drones equipped with thermal cameras can identify these temperature anomalies, helping to locate leaks quickly.

- Hyperspectral Imaging: This advanced imaging technology can detect leaks based on the chemical composition of the substance. By identifying hydrocarbons, hyperspectral cameras provide accurate detection of oil or gas leaks.

- Cost-Effective: Drones can cover large areas quickly, offering a cost-effective way to inspect pipelines without the need for ground-based personnel.

4. Cloud-Based Monitoring and Data Analytics

Cloud technology is transforming how pipeline data is processed and analyzed. Cloud-based monitoring systems aggregate data from multiple sensors, allowing operators to access real-time insights from any location. By using cloud computing, large amounts of data can be stored, processed, and analyzed to improve leak detection accuracy.

- Data Aggregation: Cloud systems combine data from different sensors, enabling a comprehensive analysis of pipeline conditions.

- Remote Access: Operators can access real-time monitoring data from anywhere, facilitating faster decision-making and response to potential leaks.

- Enhanced Analytics: Cloud platforms provide advanced data analytics, identifying trends, patterns, and anomalies that may signal a leak.

5. Electromagnetic Leak Detection

Electromagnetic leak detection is an emerging method that involves transmitting electromagnetic signals through the pipeline. Changes in the signal’s strength can indicate the presence of a leak or a change in pipeline integrity.

- Non-Invasive: This method is non-invasive, meaning the pipeline does not need to be modified or shut down for electromagnetic monitoring to occur.

- Corrosion and Crack Detection: In addition to detecting leaks, electromagnetic systems can also identify corrosion, cracks, and other structural issues that may lead to a leak.

- Real-Time Results: The system provides real-time feedback, allowing operators to respond quickly to leaks or pipeline damage.

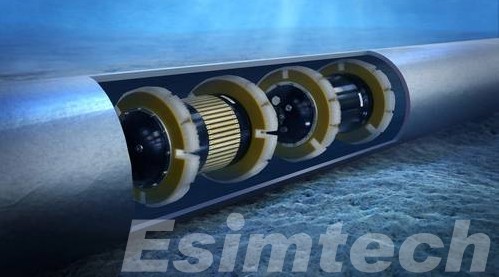

6. Smart Pigs

"Smart pigs" are advanced pipeline inspection devices that are sent through pipelines to detect leaks and structural weaknesses. These devices are equipped with sensors that gather data on the pipeline’s condition as they travel through it.

- Internal Inspection: Smart pigs can inspect the inside of pipelines, detecting corrosion, cracks, and leaks that external sensors might miss.

- Detailed Data Collection: Smart pigs collect highly detailed data, providing operators with a comprehensive view of the pipeline’s health.

- Automated Reporting: The data gathered by smart pigs is analyzed to generate automated reports, identifying any areas that require immediate attention.

How Simulation Technologies are Used for Pipeline Leak Detection

This chart highlights how various oil and gas simulation technologies are employed in pipeline leak detection, focusing on their functionality, benefits, and practical uses.

| Simulation Technology | Description | Key Benefits | Applications |

| Computational Fluid Dynamics (CFD) | Simulates the flow of liquids and gases through pipelines to predict potential leak points. | 1. Predicts flow behavior under various conditions 2. Models pipeline integrity under stress or damage | 1. Leak scenario prediction 2. Stress testing |

| Digital Twin Technology | Creates a real-time digital replica of the pipeline system to simulate leak events and responses. | 1. Real-time monitoring 2. Predictive maintenance 3. Helps in fast decision-making during leak events | 1. Remote leak detection 2. Predictive analysis |

| Acoustic Simulation | Simulates the sound waves produced by leaks to train detection systems. | 1. Detects small leaks 2. Reduces false positives 3. Models different leak sizes and locations | 1. Acoustic sensor placement 2. Leak localization |

| Hydraulic Modeling | Simulates pressure changes in pipeline systems to detect abnormal pressure drops linked to leaks. | 1. Monitors pressure trends 2. Early detection of pressure anomalies 3. Helps assess pipeline flow efficiency | 1. Real-time pressure monitoring |

| Finite Element Analysis (FEA) | Simulates mechanical stress on pipelines to identify potential weak points that could lead to leaks. | 1. Predicts structural integrity 2. Detects corrosion and mechanical wear 3. Optimizes pipeline design | 1. Structural monitoring 2. Corrosion prediction |

| Geospatial Simulation | Uses geographic data and pipeline mapping to simulate environmental impacts and leak dispersion. | 1. Models leak spread 2. Predicts environmental impact 3. Enhances emergency response planning | 1. Environmental risk assessment 2. Response strategy |

| AI-based Simulation | Uses artificial intelligence to simulate pipeline operations and predict future leak scenarios. | 1. Adaptive learning 2. Self-improving accuracy 3. Reduces false alarms | 1. Autonomous detection 2. Leak forecasting |

To sum up, through leveraging both internal and external pipeline leak detection systems and embracing new technologies such as AI, IoT, satellite monitoring, cloud-based monitoring, etc, the oil and gas industry is improving its ability to detect pipeline leaks early and mitigate their impact. However, challenges remain, particularly in detecting small leaks and managing costs.