What are Effective Drilling Waste Management Strategies

Drilling waste management is a significant aspect of the oil and gas industry, and it includes the methods and techniques used to handle, treat, and dispose of trash generated during drilling operations. Effective drilling waste management is critical for minimizing the environmental impact of drilling, ensuring regulatory compliance, and maintaining drilling operational efficiency.

Why Need Effective Drilling Waste Management

Types of Drilling Waste

| Types of Drilling Waste | Description |

| Drill Cuttings | Solid materials (e.g., rock fragments, clay, sand) generated during the drilling process. |

| Drilling Fluids | Also known as drilling mud, these are fluids circulated through the drill bit to lubricate and cool the drill bit and carry drill cuttings to the surface. |

| Produced Water | Water that comes to the surface during drilling or production, often containing dissolved minerals, hydrocarbons, and other contaminants. |

| Contaminated Soil | Soil that has been contaminated with drilling fluids, hydrocarbons, or other pollutants during drilling activities. |

| Spent Catalysts | Used catalysts employed in drilling or refining processes for various chemical reactions. |

| Drilling Wastes from Hydraulic Fracturing | Wastes generated from hydraulic fracturing operations, including flowback water and produced water containing additives and naturally occurring substances from the formation. |

| Oil-Based Mud (OBM) Cuttings | Drill cuttings contaminated with oil-based drilling fluids. |

| Synthetic-Based Mud (SBM) Cuttings | Drill cuttings contaminated with synthetic-based drilling fluid |

Challenges in Drilling Waste Management

| Challenges | Description |

| Environmental Impact | Improper disposal can lead to soil and water contamination, air pollution, and harm to ecosystems and wildlife |

| Regulatory Compliance | Stringent regulations govern waste management to protect the environment and public health. Non-compliance can result in fines, penalties, and damage to reputation |

| Operational Costs | Proper waste management requires investment in treatment technologies, disposal methods, and compliance measures, increasing operational expenses |

| Waste Volume and Composition | Large volumes of diverse waste types are generated during drilling, each requiring specific handling and treatment |

| Treatment Efficiency | Some waste components are challenging to treat effectively, requiring advanced technologies and processes |

| Resource Recovery | Maximizing resource recovery from waste streams, such as hydrocarbons and water, poses technical and economic challenges |

| Logistical Challenges | Transporting waste to treatment and disposal facilities can be logistically complex, particularly in remote or offshore locations |

| Public Perception and Stakeholder Relations | Negative public perception of drilling waste management practices can lead to reputational damage and regulatory scrutiny. Engaging stakeholders is crucial for maintaining trust and social license to operate |

| Emerging Contaminants | Rapid technological advancements in drilling operations may introduce new contaminants into waste streams, requiring updated treatment methods and regulatory oversight |

| Long-term Liability | Ensuring the long-term containment and monitoring of waste disposal sites to prevent future environmental and public health risks |

| Integration with Operations | Waste management must be seamlessly integrated into drilling operations to minimize disruption and ensure compliance |

Strategies for Drilling Waste Management

1. Prevention

- Optimized Drilling Practices: Employ advanced drilling techniques, such as directional drilling and managed pressure drilling, to minimize the volume of waste generated.

- Well Planning and Design: Conduct thorough site assessments and wellbore planning to minimize the need for excess drilling and reduce waste generation.

- Selection of Environmentally Friendly Fluids: Choose drilling fluids that are biodegradable, non-toxic, and less harmful to the environment.

2. Treatment

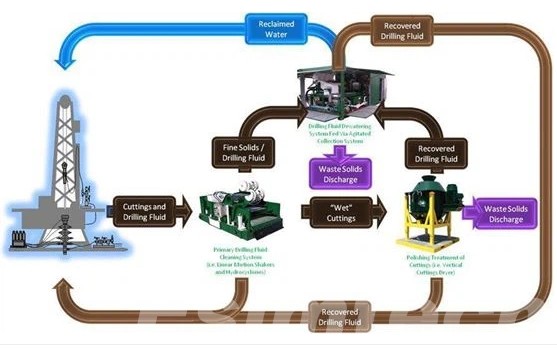

- Filtration and Separation: Utilize advanced filtration systems and separation equipment to remove solids and contaminants from drilling fluids and produce water.

- Chemical Treatment: Employ chemical additives to treat drilling fluids and produced water, facilitating the removal of contaminants and improving water quality.

- Bioremediation: Utilize naturally occurring microorganisms to degrade organic pollutants in drilling waste, offering a cost-effective and environmentally friendly treatment option.

3. Recycling and Reuse

- Drilling Fluid Recycling: Implement systems to recycle and reuse drilling fluids, reducing the need for fresh fluid intake and minimizing waste generation.

- Produced Water Treatment: Treat produced water to remove contaminants and recycle it for use in drilling operations, such as hydraulic fracturing or secondary recovery techniques.

- Material Reuse: Explore opportunities to reuse or repurpose drill cuttings and other waste materials, such as using them for construction fill or land reclamation projects.

4. Disposal

- Landfills: Dispose of non-hazardous drilling waste in properly permitted landfills that meet regulatory requirements and environmental standards.

- Injection Wells: Utilize injection wells for the disposal of drilling fluids and produced water, ensuring compliance with injection regulations and minimizing environmental impact.

- Specialized Treatment Facilities: Transport waste to specialized treatment facilities equipped to handle hazardous or complex waste streams, ensuring proper treatment and disposal.

5. Monitoring and Reporting

- Environmental Monitoring: Implement monitoring programs to assess the environmental impact of drilling operations, including air, water, and soil quality assessments.

- Regulatory Compliance: Stay informed about local, state, and federal regulations governing drilling waste management and ensure compliance with all applicable laws.

- Transparency and Reporting: Maintain accurate records of waste management activities and provide transparent reporting to regulatory authorities and stakeholders.

6. Continuous Improvement

- Research and Development: Invest in research and development to identify and implement innovative technologies and best practices for drilling waste management.

- Training and Education: Provide training and education for personnel involved in drilling operations to ensure they understand and adhere to waste management protocols.

- Collaboration and Knowledge Sharing: Foster collaboration among industry stakeholders, regulatory agencies, and environmental organizations to share best practices and promote continuous improvement in drilling waste management.

Innovations in Drilling Waste Management

1. Bioremediation

Bioremediation uses naturally occurring microorganisms to break down pollutants in drilling waste. This environmentally friendly strategy provides a low-cost alternative to existing treatment procedures and has shown encouraging results in decreasing the environmental impact of drilling operations. Bioremediation can expedite the breakdown of organic contaminants by increasing microbial activity through nutritional supplementation and proper environmental conditions, resulting in harmless byproducts.

2. Advanced Filtration Technologies

Filtration technology advancements have transformed how drilling fluids and generated water are treated. High-efficiency filtration systems using modern membranes and separation techniques may successfully remove sediments, oil, and other impurities from wastewater streams. These innovative solutions not only improve water quality but also allow for the recovery and reuse of precious resources, lowering the demand for freshwater input and wastewater disposal.

3. Zero Liquid Discharge (ZLD) Systems

Zero Liquid Discharge (ZLD) systems offer a paradigm shift in wastewater management, with the goal of eliminating liquid discharge from all industrial operations. ZLD systems concentrate wastewater using evaporation, crystallization, and solid-liquid separation processes to recover valuable resources while minimizing environmental effects.

4. Thermal Desorption

Thermal desorption is a thermal treatment technology that utilizes heat to volatilize and separate contaminants from drilling waste. By subjecting drill cuttings and contaminated soils to high temperatures in a controlled environment, thermal desorption effectively removes organic pollutants, such as hydrocarbons, without generating secondary waste streams. This innovative approach offers a safe and efficient means of remediation, minimizing environmental liabilities and facilitating the reuse or disposal of treated materials.

How Simulation Technology Used in Optimizing Drilling Waste Management

1. Predictive Modeling

Engineers can use oil and gas simulation software to construct predictive models of drilling processes, such as waste generation and movement. By entering parameters such as well depth, drilling fluid characteristics, and geological conditions, engineers can model the volume and composition of trash generated at various phases of the drilling process. Predictive modeling enables the identification of possible waste management difficulties and the development of proactive mitigation methods.

2. Treatment Process Optimization

Engineers can use simulation technology to model and optimize treatment processes for drilling waste. Engineers can determine the best treatment procedures for individual waste streams by simulating the performance of various treatment technologies such as filtration, chemical treatment, and bioremediation. Simulation enables the optimization of operating drilling parameters such as flow rates, temperatures, and chemical dosages in order to enhance treatment efficiency and minimize costs.

3. Resource Recovery Optimization

Simulation software can also be used to optimize resource recovery from drilling waste, such as hydrocarbons and water. By modeling the performance of recovery processes, such as thermal desorption or water treatment, engineers can determine the most efficient methods for recovering valuable resources from waste streams. Simulation helps optimize recovery rates, minimize resource losses, and maximize the economic value of waste materials.

4. Environmental Impact Assessment

Simulation technology facilitates the assessment of the environmental implications of drilling waste management activities. Engineers can simulate the dispersion of toxins in soil, water, and air to assess environmental concerns and devise mitigation strategies. Simulation enables the prediction of long-term environmental repercussions, such as soil and water contamination, and aids in regulatory compliance.

Conclusion

Effective drilling waste management is critical to the sustainable operation of oil and gas exploration and production operations. By following best practices, investing in novel technology, and ensuring regulatory compliance, the industry may reduce its environmental impact while protecting ecosystems and communities. As energy demand rises, responsible waste management procedures will become increasingly important in guaranteeing the long-term viability and sustainability of the oil and gas sector.