What are Commonly Used Oil Drilling Tools: Evolution, Types and Innovations

For almost a century, the oil and gas industry has played a critical role in the global economy, providing the vital energy resources that power our modern world. Behind the scenes of this massive enterprise is a world of invention and technology, including the creation of improved oil drilling instruments. These tools are the unsung heroes of the petroleum industry, allowing hydrocarbons to be extracted from deep beneath the Earth’s surface. In this essay, we will dig into the intriguing world of oil drilling tools, investigating their evolution, types, innovations, and important functions in the oil and gas extraction process.

What is the Evolution of Oil Drilling Tools

The evolution of oil drilling tools is an intriguing trip that parallels the evolution of the oil and gas sector itself. Drilling tools have been essential in freeing massive energy resources from deep under the Earth’s crust, progressing from rudimentary manual methods to highly modern, computer-controlled technology. While effective to some extent, these approaches were restricted in their ability to penetrate deep reservoirs.

Rotary Drilling

Rotary drilling developed as a major changer in the business in the late nineteenth century. This method used a rotary bit attached to a drilling string, which allowed for faster and deeper drilling. It was a big step forward, opening up previously inaccessible oil deposits.

Tri-cone Bits

The development of tri-cone bits in the early twentieth century significantly altered drilling technique. These bits have three revolving cones with teeth that could crush and drill through rocks faster than previous designs.

Diamond Bits

Diamond drill bits, introduced in the mid-twentieth century, improved drilling precision and durability. Industrial-grade diamonds were used in these bits to cut through the harshest rock formations.

What are the Key Oil Drilling Tools in Modern Drilling Operations

To extract hydrocarbons from increasingly difficult locations, the oil and gas sector now relies on a diverse set of modern oil drilling tools and equipment.

Drill Bits

PDC (Polycrystalline Diamond Compact) Bits: PDC bits feature synthetic diamond cutters. These bits are extremely robust and can efficiently drill through hard rock formations.

Roller Cone Bits: Roller cone bits are revolving cones with teeth that can work with a variety of forms. They are versatile and adaptable, making them a popular choice for various drilling conditions.

Mud Motors (Positive Displacement Motors – PDMs)

Mud motors are downhole devices that transform drilling fluid hydraulic pressure into mechanical energy to move the drill bit. They provide accurate drilling control, improve drilling efficiency, and lengthen the life of the drill bit.

Directional Drilling Tools

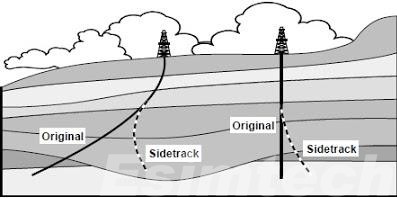

Downhole Motors: Downhole motors, combined with measurement-while-drilling (MWD) systems, enable operators to control the trajectory of the wellbore. This technology is essential for reaching distant subsurface targets and drilling multiple branches from a single well.

Measurement-While-Drilling (MWD) and Logging-While-Drilling (LWD) Tools

While drilling is taking place, MWD and LWD equipment give real-time data on well conditions and geology. These technologies improve drilling precision, allowing operators to make more informed decisions and optimize drilling settings.

Casing and Cementing Equipment

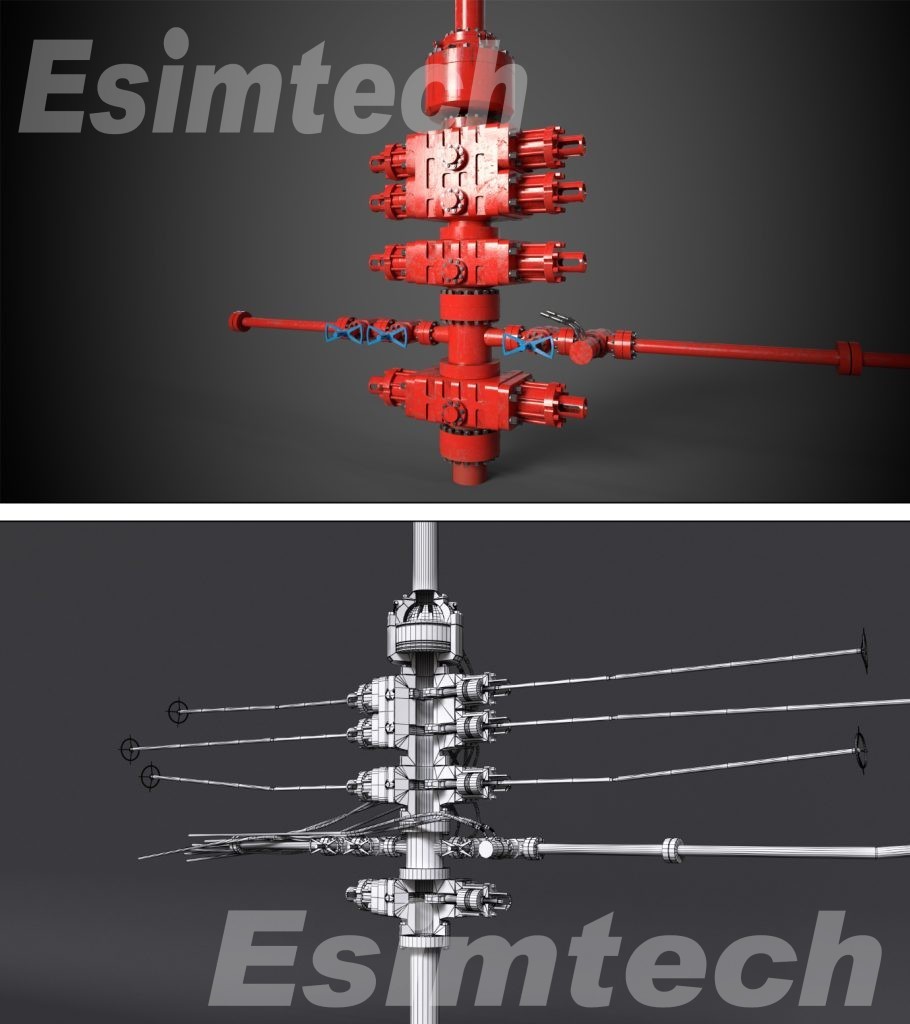

Casing and cementing equipment are essential for maintaining the structural integrity of the well and limiting fluid migration. Proper casing and cementing are essential for well safety and environmental protection.

Top Drive Systems

Top drive systems are motorized systems that rotate the drill string from the top, replacing typical rotary tables and kellys. This improves drilling efficiency and removes the need for human pipe handling.

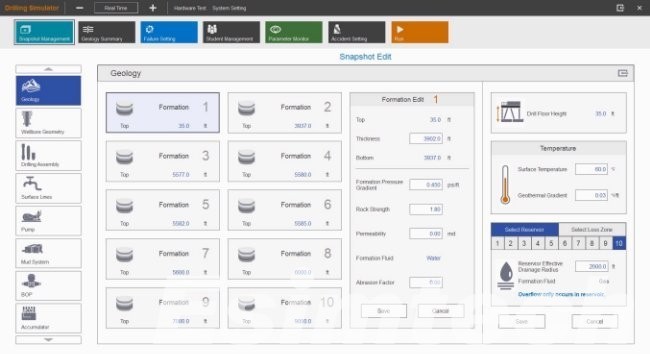

The top drive simulation training system was created with the goal of training the functioning of the top drive device.It may provide training for all top drive operations as well as common accident handling.It can be utilized for driller/driller assistant, technician, and drilling team leader training. Trainees can master the operating method of top drive and the handling skill of common mishaps by training with the system.

The simulator employs numerous mathematical models to simulate the operation of the top drive, taking into account the changing rules of various factors. Event-driven simulation technology may model diverse device operations, bringing training closer to reality. Accident pre-set technology simulates common accidents and gadget flaws, allowing the instructor to enter the accidents or flaws at any moment. The trainee can then judge the phenomenon and take appropriate action. This enhances their ability to judge and handle accidents. Virtual reality technology creates a perceptual environment. 3D oil engineering animation that is synchronized with operation displays the site scene, together with a rich sound effect. All of this contributes to an immersive training experience.

Automated Drilling Rigs

Drilling rigs that are automated are outfitted with advanced control systems and robotics, decreasing the need for human interaction. These rigs improve total drilling efficiency by increasing safety and operating 24 hours a day, seven days a week.

Advanced Drill Pipe Materials

Modern drill pipes are frequently constructed of high-strength, corrosion-resistant materials such alloy steel or composite composites. These compounds improve the drill string’s resilience and longevity.

Drilling Fluids and Mud Systems

Advanced drilling fluids, or drilling muds, are formulated to optimize drilling performance and wellbore stability. These fluids are designed to minimize friction, cool the drill bit, and remove cuttings from the wellbore.

Drilling Software and Data Analytics

Modern drilling operations rely on sophisticated oil and gas software for data analysis and decision-making. These tools help optimize drilling parameters, detect potential issues, and improve overall drilling efficiency.

What are the Challenges and Innovations for Oil Drilling Tools

The oil and gas industry is confronted with a slew of issues, ranging from technical and operational difficulties to environmental and sustainability problems. These challenges, however, have sparked a never-ending cycle of innovation aimed at enhancing efficiency, safety, and sustainability.

Exploration and Reservoir Challenges

Challenge: As easily accessible oil fields are depleted, finding and accessing new deposits becomes increasingly complex.

Innovation: Advanced seismic imaging technologies, such as 3D and 4D seismic surveys, aid in the more accurate identification of subterranean reserves. Furthermore, advanced drilling methods such as extended-reach drilling and directional drilling enable operators to more successfully access remote or difficult reservoirs.

Environmental Concerns

Challenge: The influence of oil and gas exploration, production, and transportation on the environment, including pollutants, habitat damage, and oil spills.

Innovation: Environmentally friendly drilling fluids, low-emission drilling technology, and environmental monitoring systems are all helping to decrease the industry’s impact. Furthermore, projects such as renewable energy integration and carbon capture and storage (CCS) seek to reduce the industry’s carbon footprint.

Safety and Well Integrity

Challenge: It is critical to ensure personnel safety and to prevent well blowouts and leaks.

Innovation: Blowout preventers (BOPs), Well control and safety can be improved by using managed pressure drilling (MPD) systems and real-time monitoring technologies supplied by a full drilling and well control simulation system. Advances in materials science and engineering continue to improve well integrity and casing designs.

Operational Efficiency

Challenge: Increasing output while reducing downtime and expenses is a continual problem.

Innovation: Automation and robotics, such as self-driving rigs and remotely operated vehicles (ROVs), eliminate human interference while increasing operating efficiency. Predictive maintenance, data analytics, and digital twins optimize equipment performance and reduce unplanned downtime.

Deepwater and Harsh Environments

Challenge: Deepwater and harsh environment drilling involve distinct technical obstacles.

Innovation: Specialized equipment, subsea technology, and materials that can withstand extreme pressure and temperature conditions enable drilling in deepwater and harsh environments. Advances in offshore drilling technology, including floating production systems and riser systems, have expanded exploration opportunities.

Regulatory Compliance

Challenge: Adhering to stringent environmental and safety regulations can be complex and costly.

Innovation: Drilling methods and equipment improvements aid in meeting regulatory requirements, while digital reporting and monitoring systems ease compliance efforts.

Energy Transition

Challenge: The global move toward renewable energy sources, as well as the need to minimize greenhouse gas emissions, call into question the fossil fuel industry’s long-term survival.

Innovation: Oil and gas firms are diversifying into renewable energy areas such as wind and solar, as well as investing in low-carbon research. CCS initiatives seek to capture and store carbon emissions from fossil fuel operations.

Geopolitical and Market Volatility

Challenge: Oil price fluctuations and global unrest can interrupt industry operations.

Innovation: To respond to market changes and geopolitical concerns, businesses are implementing risk mitigation techniques, diversifying portfolios, and improving operations.

Summary

Oil drilling tools have progressed from their basic beginnings to complex and high-tech equipment that powers the worldwide oil and gas industry. As the sector faces new problems and environmental concerns, continual drilling tool innovation is critical. These improvements not only allow for more effective hydrocarbon extraction, but they also contribute to the industry’s sustainability and environmental responsibility.