What are Advancements Enabling High-temperature Well Logging

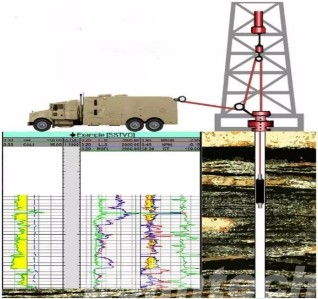

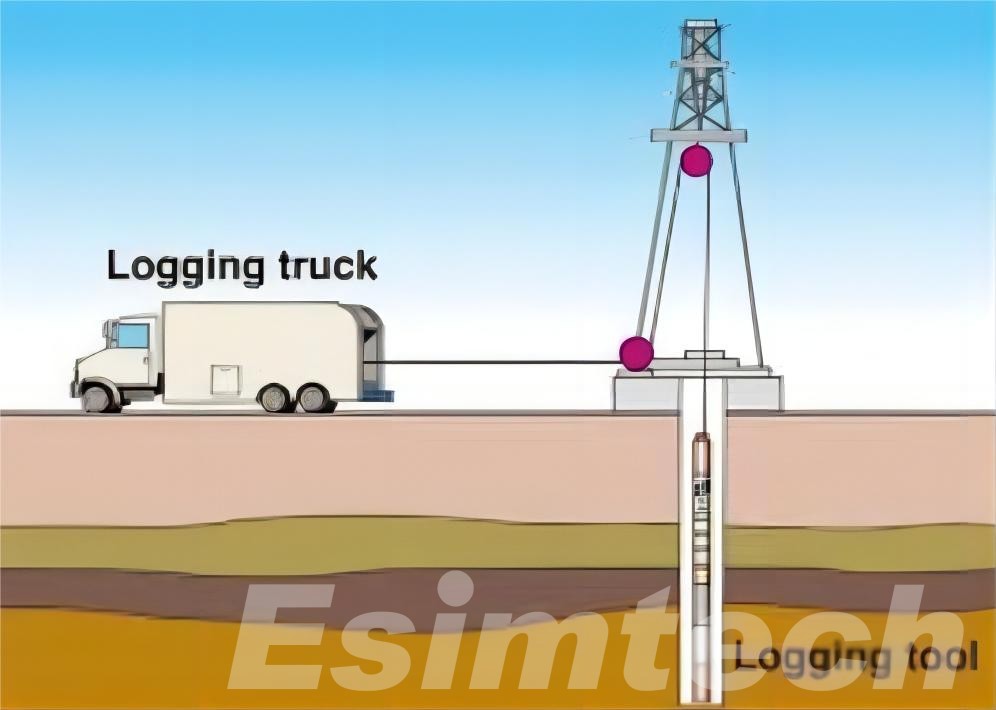

As drilling projects push into hotter and more challenging environments, the need for advanced well logging technologies capable of withstanding extreme high temperatures becomes increasingly critical. This well logging process involves acquiring vital data about the geological formations and fluid properties within a well, providing invaluable insights for decision-making during oil and gas exploration and production.

The Significance of Advanced Well Logging Tools in High-temperature Environments

High-temperature wells, commonly exceeding 150°C (300°F), are often associated with deeper reservoirs or geothermal fields. Such environments pose significant challenges to conventional logging tools and techniques. The materials, electronics, and sensors used in standard equipment may fail under extreme conditions, leading to unreliable data or operational downtime. To address these challenges, high-temperature well logging tools are engineered with specialized materials, advanced electronics, and innovative cooling mechanisms.

These advanced well logging tools enable the collection of accurate data even in harsh conditions, ensuring operators gain a clear understanding of the subsurface environment. For instance, high-temperature logging tools are crucial for identifying potential hydrocarbon zones, determining porosity and permeability, and evaluating reservoir fluids.

Key Innovations in High-temperature Well logging

1. Advanced Materials for Extreme Conditions

One of the fundamental challenges in high-temperature well logging is protecting logging tools and sensors from heat-induced damage. Recent advancements in material science have introduced high-performance ceramics, specialized polymers, and heat-resistant alloys. These materials provide superior thermal stability, ensuring that components can function seamlessly in temperatures exceeding 175°C (350°F) and, in some cases, up to 300°C (570°F).

Innovative coatings have also been developed to shield sensitive electronics from corrosive and high-pressure environments often encountered in deep wells. These coatings extend the lifespan of the tools and reduce operational costs by minimizing the frequency of replacements or repairs.

2. Enhanced Sensor Technology

The development of sensors that maintain accuracy at elevated temperatures has been a major breakthrough in high-temperature well logging. Advances include:

- Resistivity Sensors: Modern resistivity logging tools use advanced electronics capable of maintaining consistent performance under extreme heat. These sensors offer detailed insights into the electrical properties of formations, critical for identifying hydrocarbon-rich zones.

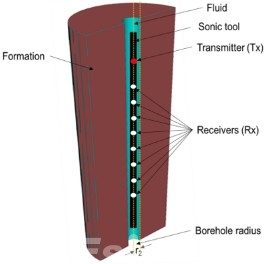

- Acoustic Sensors: High-temperature acoustic sensors leverage piezoelectric materials that remain functional at high temperatures. These tools are used for measuring formation porosity and detecting fractures.

- Thermal Gradient Sensors: Specialized thermal sensors provide real-time data on temperature profiles, essential for geothermal applications and wellbore stability analysis.

3. High-temperature Electronics

Traditional electronics often fail in high-temperature environments, but advancements in semiconductor technology have addressed this limitation. Silicon carbide (SiC) and gallium nitride (GaN) semiconductors are now employed in well logging tools due to their ability to operate efficiently under high thermal stress. These materials enable the design of compact, energy-efficient circuits that remain stable at extreme temperatures.

Furthermore, innovative power management systems have been integrated into logging tools, allowing consistent operation without overheating. These systems ensure reliable performance, even during extended logging operations.

4. Real-time Data Transmission

Real-time data transmission has become a critical aspect of well logging. Modern telemetry systems utilize robust signal processing algorithms and heat-resistant communication cables to maintain data integrity. Some tools employ wireless telemetry, which eliminates the need for cables and reduces the risk of damage during operations.

Real-time data transmission enables faster decision-making during drilling, as geologists and engineers can analyze subsurface information as it is collected. This reduces downtime and enhances the overall efficiency of exploration projects.

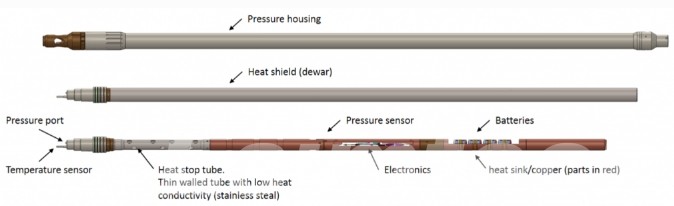

5. Cooling Mechanisms

To combat the thermal stress on logging tools, innovative cooling mechanisms have been developed. Passive cooling systems use phase-change materials that absorb heat and maintain a stable temperature within the tool. Active cooling methods, such as circulating fluid systems, are also employed in certain high-temperature applications.

These cooling technologies ensure that sensitive components remain within operational temperature ranges, preventing overheating and ensuring consistent data acquisition.

6. Artificial Intelligence and Data Analytics

The integration of artificial intelligence (AI) and advanced data analytics has significantly enhanced the interpretation of high-temperature well logging data. AI algorithms process vast amounts of data in real time, identifying patterns and anomalies that might go unnoticed through manual analysis.

Machine learning models are also used to predict equipment performance and optimize tool configurations for specific well conditions. This predictive capability reduces the risk of equipment failure and improves the accuracy of logging operations.

Challenges and Future Directions in High-temperature Well Logging

This chart outlines how current challenges are being addressed through innovative approaches, paving the way for more reliable and efficient high-temperature well logging systems.

| Category | Challenges | Future Directions |

| Materials | – Degradation of conventional materials under extreme heat and pressure. | – Development of advanced alloys, ceramics, and composites with higher thermal resistance. |

| Sensors | – Loss of accuracy and functionality at high temperatures. | – Miniaturized and robust high-temperature sensors for precise measurements. |

| Electronics | – Thermal instability of standard semiconductors and circuit components. | – Use of SiC and GaN semiconductors for better performance under extreme heat. |

| Data Transmission | – Signal loss and interference during real-time data transmission in harsh conditions. | – Improved telemetry systems, including wireless and high-bandwidth communication. |

| Tool Longevity | – High wear and tear due to extreme operating conditions. | – Advanced protective coatings and modular designs for easy maintenance and replacement. |

| Cooling Systems | – Inefficiency of traditional cooling methods in extreme environments. | – Innovative passive and active cooling systems, such as phase-change materials and fluid circulation. |

| Cost | – High costs of developing and deploying specialized high-temperature tools. | – Cost-effective designs using scalable manufacturing processes and reusable components. |

| Data Interpretation | – Complexity of analyzing vast data sets from extreme environments. | – Integration of AI and machine learning for real-time analysis and predictive modeling. |

| Operational Risks | – Equipment failure leading to costly downtime and safety risks. | – Enhanced reliability through predictive maintenance and autonomous logging technologies. |

| Depth and Reach | – Limited depth capabilities of current tools. | – Development of ultra-deep well logging tools with extended reach and durability. |

Simulations Used for High-Temperature Well Logging

High-temperature well logging relies heavily on advanced simulations to ensure tools and techniques can withstand and perform accurately in extreme environments. These well logging simulations are essential for designing, testing, and optimizing equipment and operational procedures before deploying them in high-cost, high-risk field operations.

1. Thermal simulations

One of the primary uses of simulation in high-temperature well logging is to model the thermal dynamics of the well environment. By recreating the temperature gradients, pressures, and fluid properties of deep wells, engineers can evaluate the performance of logging tools. These simulations allow for the identification of potential failures, such as overheating or material degradation, and guide the selection of heat-resistant materials and components.

2. Finite Element analysis (FEA) Simulations

Mechanical stress simulations are also important. High temperatures often amplify the mechanical loads on tools due to thermal expansion and pressure variations. Finite element analysis (FEA) is used to predict how these factors affect tool integrity, ensuring components can endure the combined thermal and mechanical stresses encountered during operations.

3. Data Acquisition and Transmission Simulations

They address the challenges of maintaining signal fidelity in high-temperature environments. Virtual models replicate how telemetry systems operate under thermal and electromagnetic interference. These simulations enable engineers to design robust communication protocols and hardware that ensure data remains reliable and consistent throughout logging operations.

4. Fluid Dynamics Simulations

They are critical for understanding how wellbore fluids interact with logging tools in high-temperature settings. These simulations explore heat transfer, flow behavior, and cooling efficiency. Computational fluid dynamics (CFD) is frequently employed to optimize the design of active and passive cooling mechanisms that protect sensitive components.

5. Geological Simulations

geological simulations help anticipate how different rock formations and fluid compositions influence sensor readings. These models replicate the interaction between the sensors and subsurface materials, ensuring that tools are calibrated for accurate data collection even in complex, high-temperature environments.

Summary

The advancements in high-temperature well logging is a critical enabler of modern energy exploration, offering the precision and reliability needed to navigate the complexities of extreme subsurface environments. Through adopting cutting-edge technologies and overcoming operational challenges, it provides the foundation for safer, more efficient, and economically viable resource extraction.