Wellbore Integrity vs. Wellbore Stability: How to Address Both Challenges in Complex Reservoirs

Wellbore integrity and wellbore stability are two critical aspects of drilling operations, particularly in complex reservoir environments. While both terms may seem similar, they represent distinct challenges that require different approaches to mitigate.

Overview of Wellbore Integrity and Wellbore Stability

Wellbore Integrity

Wellbore integrity refers to the ability of the wellbore to maintain its structural integrity throughout the life cycle of the well. This encompasses preventing leaks, maintaining pressure containment, and ensuring that the materials used (such as casing, cement, and seals) can withstand the environmental conditions encountered. Wellbore integrity is vital to prevent unwanted fluid migration, which can lead to environmental contamination and pose serious risks to personnel and equipment.

Factors influencing wellbore integrity include:

- Material Selection: The choice of casing and cement materials must withstand the pressures and temperatures found in the reservoir.

- Well Design: Properly designed well trajectories and drilling practices can enhance integrity by minimizing stress concentrations.

- Operational Practices: Maintaining proper cementing techniques and monitoring for gas influx or fluid loss during drilling operations are essential to ensure integrity.

Wellbore Stability

Wellbore stability refers to the wellbore’s capacity to endure the geomechanical forces acting upon it without failing or collapsing. It emphasizes the relationship between the wellbore and the surrounding geological formations. Ensuring stability is vital to prevent wellbore collapse, excessive deformation, and incidents involving stuck pipes.

Several key factors influence wellbore stability:

- Formation Properties: The mechanical characteristics of the surrounding rock, such as strength and elasticity, play a critical role in maintaining stability.

- Fluid Pressures: The pressures exerted by drilling fluids and formation fluids can impact the force balance acting on the wellbore.

- Geological Structures: The presence of faults, fractures, and layering within the reservoir can introduce additional stresses that may jeopardize stability.

Wellbore Integrity vs. Wellbore Stability: Comparative Analysis

Wellbore integrity and wellbore stability, while closely related, represent distinct aspects of the drilling process, each with its unique implications and challenges. Understanding their differences and similarities is essential for effectively managing both during drilling operations.

Similarities

Both wellbore integrity and wellbore stability are crucial for successful drilling and production operations, as failures in either can lead to significant operational challenges, safety hazards, and financial losses. Here are a few key similarities:

- Impact on Operations: Failures in wellbore integrity can lead to uncontrolled fluid release, resulting in blowouts and environmental contamination. Similarly, stability failures can cause wellbore collapse or stuck pipe incidents, leading to non-productive time (NPT) and increased costs.

- Influence on Well Design: Both aspects require meticulous planning and consideration during the well design phase. Engineers must evaluate geological conditions and material properties to ensure that the design optimally supports both integrity and stability throughout the well’s life cycle.

Differences

Although wellbore integrity and wellbore stability are interconnected, they differ significantly in their failure mechanisms and assessment methods:

- Mechanisms of Failure

- Wellbore Integrity: Failures in wellbore integrity can occur due to factors such as material degradation, corrosion, improper cementing practices, or inadequate casing design. The primary focus is on maintaining pressure containment and preventing fluid migration.

- Wellbore Stability: Failures related to wellbore stability typically stem from external geomechanical forces impacting the wellbore, including changes in formation pressure, stress distributions, and geological anomalies. The main concern is ensuring that the wellbore remains structurally sound and capable of resisting these forces.

- Assessment Techniques

- Integrity Assessment: Various techniques, such as pressure tests, cement bond logs, and monitoring for gas influx during drilling operations, are utilized to evaluate the wellbore’s integrity and its capacity to contain fluids.

- Stability Assessment: Geomechanical modeling, rock mechanics analysis, and in-situ measurements are employed to assess wellbore stability, with a focus on the surrounding rock formations and their mechanical properties.

In summary, while wellbore integrity and wellbore stability are both vital components of successful drilling operations, they address different challenges and require unique assessment methods. Recognizing their differences and interdependencies is crucial for optimizing drilling strategies, especially in complex reservoir environments where the risks of integrity and stability failures are heightened. By adopting a holistic approach that incorporates both aspects, operators can enhance safety, reduce operational costs, and improve overall well performance.

Challenges in Complex Reservoirs: Interplay Between Integrity and Stability

Complex reservoirs present a unique set of challenges that intertwine wellbore integrity and wellbore stability, making effective management essential for successful drilling operations. These reservoirs, often characterized by heterogeneous geological formations, varying fluid pressures, and unpredictable fault systems, create a challenging environment that requires a deep understanding of both integrity and stability to mitigate risks. Here’s an in-depth exploration of the interplay between these two critical aspects in complex reservoirs.

Geological Complexities

- Heterogeneous Lithology: Complex reservoirs often contain a mix of rock types, each with different mechanical properties. Variations in strength, permeability, and porosity can lead to localized stress concentrations. For instance, a wellbore drilled through a hard rock formation may experience greater stress than one drilled through softer rock, leading to potential failure points. This heterogeneity complicates predictions of wellbore behavior and requires tailored strategies for maintaining both integrity and stability.

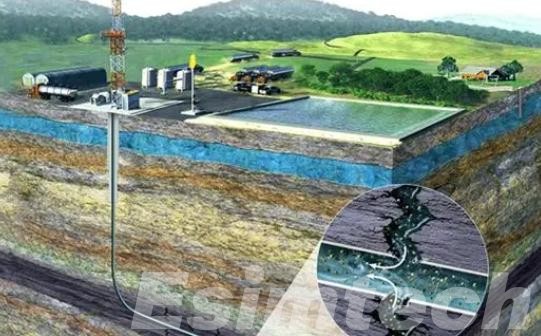

- Fault Zones: The presence of active or ancient fault zones within a reservoir can create significant challenges. These zones can induce irregular stress fields, leading to unexpected shifts in the surrounding rock, which can compromise both the integrity of the well casing and the stability of the wellbore. Fracturing within these zones can also lead to the migration of fluids, which may undermine wellbore integrity and increase the risk of blowouts or leaks.

- Natural Fractures: Complex reservoirs frequently exhibit a network of natural fractures that can alter fluid flow paths and stress distributions. While some fractures can enhance permeability and facilitate hydrocarbon extraction, others may pose risks to wellbore stability by creating zones of weakness. Fluid ingress into these fractures can lead to increased pore pressures, further destabilizing the wellbore structure and risking integrity failures.

Pressure Regimes and Fluid Dynamics

- Variable Pressure Regimes: Complex reservoirs often contain both high-pressure and low-pressure zones, resulting in rapid fluctuations in stress conditions around the wellbore. These pressure differentials pose significant challenges to maintaining wellbore integrity, especially if the density of the drilling fluid does not properly match the formation pressures. A well that experiences a sudden influx of formation fluids may suffer a loss of integrity, potentially leading to catastrophic well control incidents.

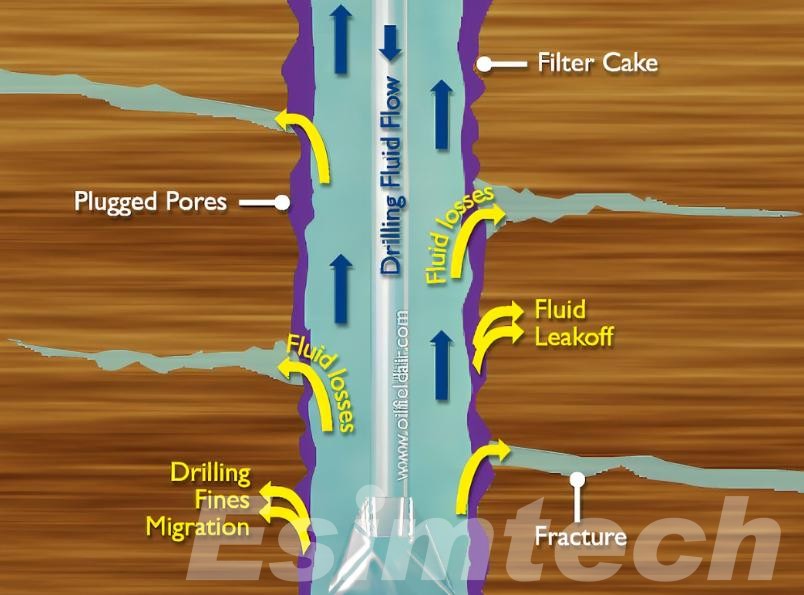

- Fluid Invasion: The interaction between drilling fluids and formation fluids can complicate wellbore stability even further. When drilling fluids invade permeable formations, they can alter the effective stress on the wellbore. This invasion may cause clays to swell or destabilize the surrounding rock, increasing the risk of wellbore collapse or failure. Understanding these fluid dynamics is essential for preserving both wellbore integrity and stability.

Interconnected Risk Factors

- Feedback Loops: The relationship between integrity and stability can create feedback loops where a failure in one aspect exacerbates problems in the other. For instance, if wellbore stability is compromised due to geological stresses, it may lead to casing deformation, which in turn can create pathways for fluid migration, undermining wellbore integrity. Conversely, if integrity is lost due to cement failure, the influx of formation fluids can increase pore pressure and lead to instability.

- Decision-Making Complexities: The interplay between wellbore integrity and stability necessitates a careful balance in operational decision-making. Engineers must consider the trade-offs between drilling parameters, fluid properties, and casing design to minimize risks associated with both integrity and stability. Poor decision-making in one area can have cascading effects, leading to increased downtime, cost overruns, and safety hazards.

Addressing the challenges of wellbore integrity and stability in complex reservoirs necessitates a thorough understanding of geological and operational factors. Recognizing the interconnected risks and employing advanced modeling, real-time monitoring, and adaptive drilling practices are essential. A proactive, integrated approach to managing these challenges enhances drilling success and ensures safer, more efficient operations in difficult environments.

Strategies for Addressing Both Challenges

To effectively address the challenges of wellbore integrity and stability in complex reservoirs, a holistic approach is required. Here are some key strategies:

- Integrated Design Approach

- Geomechanical Modeling: Implement advanced geomechanical models that incorporate real-time data from drilling operations. These models can help predict stress changes around the wellbore and inform design adjustments that enhance both integrity and stability.

- Cementing Technologies: Utilize advanced cementing techniques, such as expandable cement systems and smart cements, that can adapt to changing conditions in the reservoir, ensuring both sealing and structural support.

- Monitoring and Evaluation

- Real-time Monitoring: Employ real-time monitoring systems that track pressure, temperature, and deformation within the wellbore. This data can provide insights into the state of integrity and stability, enabling timely interventions if problems arise.

- Regular Inspections: Implement a schedule of inspections using tools like ultrasonic testing, electromagnetic scanning, and fiber optic sensors to detect early signs of integrity or stability issues.

- Adaptive Operational Practices

- Controlled Drilling Parameters: Adjust drilling parameters based on real-time feedback from formation responses to minimize stress and avoid compromising the wellbore structure.

- Drilling Fluid Optimization: Tailor drilling fluid properties to enhance wellbore stability while ensuring that the integrity of the formation and casing is maintained.

- Collaboration and Knowledge Sharing

- Cross-disciplinary Collaboration: Foster collaboration between geologists, engineers, and drilling personnel to ensure a comprehensive understanding of both wellbore integrity and stability issues.

- Knowledge Sharing: Create a knowledge-sharing platform to compile case studies and lessons learned from past drilling operations, which can guide future projects in complex reservoirs.

All in all, while wellbore integrity and wellbore stability are distinct challenges in drilling operations, their interrelationship is critical, especially in complex reservoirs. By adopting integrated design approaches, real-time monitoring, adaptive operational practices, and fostering collaboration, operators can effectively manage both integrity and stability challenges. This not only enhances the safety and efficiency of drilling operations but also contributes to the overall success of oil and gas exploration in increasingly complex environments.