Well Workover vs Well Intervention: What are the Differences

Within the oil and gas industry, maintaining well performance is crucial. This often involves interventions, but the specific approach can vary greatly. Understanding the key differences between well workover and well intervention is essential for choosing the right option to optimize your well’s operation.

What is Well Workover?

Well workover stands as a comprehensive operation within the oil and gas industry, strategically undertaken on existing wells to rejuvenate or amplify their production capabilities. This process encompasses substantial interventions and the deployment of significant equipment to address a spectrum of issues, ultimately aiming to improve the overall performance of the well. Well workovers become imperative when a well experiences a decline in production or encounters mechanical challenges that necessitate remedial action.

Common Objectives of Well Workover

- Restoring Production:

Well workovers are often initiated with the goal of restoring or enhancing production rates. This may involve the removal of obstructions, thorough cleaning of the wellbore, or the repair of damaged equipment. By addressing these impediments, operators can optimize the well’s functionality and boost production.

- Changing Completion Design:

Modification of the well’s completion design is a common facet of well workovers. This may entail actions such as replacing tubing, installing new downhole equipment, or optimizing the artificial lift system. These adjustments are geared towards improving the efficiency and effectiveness of the well’s completion design.

- Sidetracking Operations:

Some well workovers encompass sidetracking, a process that involves drilling a new borehole from an existing wellbore. This technique is employed to access additional reservoir zones, effectively bypass damaged sections, or maximize recovery from the reservoir. Sidetracking adds a layer of flexibility to well workovers, allowing operators to strategically tap into untapped resources.

In essence, well workovers play a crucial role in the lifecycle of an oil or gas well. They serve as proactive measures to counteract production challenges and mechanical issues, ensuring that the well operates at its optimal capacity. By addressing specific concerns and employing strategic modifications, well workovers contribute significantly to the sustained success and longevity of wells in the oil and gas industry.

What is Well Intervention?

Well intervention in the context of oil and gas wells refers to a set of activities aimed at diagnosing, maintaining, or enhancing the performance of a well without resorting to major interventions or workovers. These interventions are crucial for optimizing production, addressing specific issues, and ensuring the continued functionality of the well. Unlike major workovers, which involve substantial interventions, interventions are generally minor in nature and focus on improving well productivity and efficiency.

Here are some common well intervention activities:

- Well Stimulation:

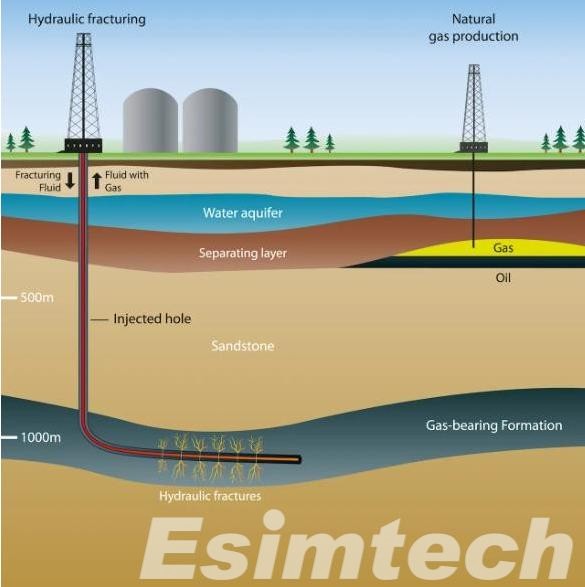

Well stimulation involves various techniques, with hydraulic fracturing (fracking) and acidizing being prominent examples. Hydraulic fracturing entails injecting high-pressure fluids into the reservoir to create fractures, enhancing reservoir connectivity and permeability. Acidizing involves the injection of acid into the well to dissolve materials obstructing fluid flow and improve well productivity.

- Well Logging and Diagnostics:

Well logging and diagnostics involve the deployment of specialized tools and instruments downhole. These tools gather data on reservoir properties, wellbore conditions, and fluid characteristics. The collected data aids in reservoir evaluation and helps optimize production strategies by providing insights into the well’s current status.

- Maintenance and Servicing:

Maintenance and servicing interventions encompass routine activities aimed at preserving the well’s functionality. This includes cleaning the wellbore to remove debris and scale, replacing damaged or worn-out equipment, and addressing minor mechanical issues. Regular maintenance is essential to prevent larger problems and maintain the well’s efficiency over time.

Intervention activities are crucial throughout the life cycle of an oil or gas well. They play a vital role in extending the well’s productive life, improving reservoir performance, and maximizing the overall recovery of hydrocarbons. Well-designed and executed intervention strategies contribute to the sustainable and efficient operation of oil and gas fields.

Key Differences Between Well Intervention and Well Workover

While both well workover and well intervention aim to address issues and improve well performance, their key differences lie in the purpose, scale, equipment used, Wellhead access, etc. Here is a sheet summarize the key difference:

| Feature | Well Workover | Well Intervention |

| Purpose | Major repairs, production enhancement, life extension | Maintenance, optimization, diagnostics |

| Scale | Extensive modifications | Smaller-scale operations |

| Equipment | Drilling/workover rig | Coiled tubing, wireline, HWU |

| Wellhead access | Removed and reinstalled | Remains intact |

| Disruption | Significant production downtime | Minimal downtime |

| Cost | High | Lower |

| Complexity | High | Lower |

Choosing the Right Option Between Well Intervention and Well Workover

Picking between a well workover and a well intervention can be a tough call. Both have their pros and cons, and the best choice ultimately depends on the specific needs of your well. Here’s a deeper dive into the factors to consider:

1. Problem Severity

Major Issues: If your well is suffering from significant production decline, blocked completions, or severe casing damage, a workover is likely the answer. Its extensive capabilities can tackle complex problems and restore well performance.

Minor Concerns: For less critical issues like instrumentation malfunction, scale buildup, or needing to perform diagnostics, a well intervention is the more efficient and cost-effective option.

2. Production Impact

Minimal Downtime: If keeping your well online is crucial, interventions are the clear winner. Their smaller scale and specialized equipment allow for quicker operations with minimal disruption to production.

Extended Shutdowns: For major repairs or modifications that require complete well access, a workover is unavoidable. However, careful planning and scheduling can minimize downtime during the process.

3. Budget Constraints

Cost-Effectiveness: Interventions are generally much lighter on the wallet compared to workovers. Their simpler operations and shorter duration translate to lower costs, making them ideal for budget-conscious operators.

Significant Investment: Workovers represent a substantial financial commitment. The mobilization of rigs, complex procedures, and specialized equipment all contribute to the higher price tag.

4. Additional Factors to Consider

Well Age and Condition: Older wells or those with existing damage might be more susceptible to complications during workovers. Interventions offer a less risky approach in such cases.

Formation Characteristics: The depth, pressure, and temperature of the reservoir can influence the feasibility and effectiveness of different techniques. Consulting with experienced professionals is crucial for choosing the right approach for your specific formation.

Environmental Regulations: Certain regions have strict regulations regarding well interventions and workovers. Make sure your chosen method complies with all applicable environmental standards.

Conclusion

Within the ever-changing terrain of the oil and gas sector, the maintenance of wells emerges as a pivotal element in securing continuous production and optimizing reservoir recovery. Both well workover and well intervention stand out as indispensable instruments in the industry’s repertoire, each designed to fulfill specific roles. The ability to discern the variances between these methodologies empowers operators to make well-informed choices, enabling them to select the most fitting intervention strategy tailored to the distinctive features and obstacles encountered by each well. Ultimately, the upkeep and fine-tuning of wells play a central role in bolstering the overall efficiency and triumph of oil and gas operations.