Well Intervention in Mature Fields: Strategies for Extending Production Life

As oil and gas fields mature, maintaining and enhancing production becomes increasingly challenging. Well intervention, the process of managing and improving well performance, plays a crucial role in extending the life of these mature fields. This article delves into the various strategies employed in well intervention, highlighting their significance in sustaining production levels.

Challenges of Mature Fields

Mature oil and gas fields present a complex web of challenges that hinder their ability to produce hydrocarbons efficiently.

- Declining Reservoir Pressure: As oil and gas are extracted, the natural pressure within the reservoir that pushes these fluids towards the wellbore depletes. This decline in pressure significantly impacts well flow rates, making it increasingly difficult to bring oil and gas to the surface economically. Operators may need to resort to artificial lift methods like gas lift or electrical submersible pumps (ESPs) to overcome this challenge, which adds complexity and cost to production.

- Water Cut: Over time, water naturally encroaches into the reservoir from surrounding formations. When produced alongside oil and gas, this water “cuts” into the overall hydrocarbon flow, reducing the well’s productivity. High water cut not only decreases the volume of valuable oil and gas being produced but also adds to processing and disposal costs.

- Bypassed Oil: During initial field development, limitations in technology and understanding of the reservoir geology may lead to zones containing recoverable oil being left untapped. These “bypassed zones” can hold significant volumes of oil, but accessing them later requires sophisticated intervention techniques like infill drilling or horizontal wellbores, which can be expensive and technically challenging.

- Aging Infrastructure: Mature fields often have aging wellbores, pipelines, and surface processing facilities. These components are more susceptible to corrosion, leaks, and mechanical failures, leading to increased maintenance costs, safety risks, and potential production downtime. Upgrading or replacing aging infrastructure can be a significant financial investment.

- Data Limitations: Older fields may have limited historical data on reservoir characteristics and production performance. This lack of data can make it difficult to accurately diagnose production problems and identify the most effective intervention strategies. Modern data acquisition and analysis techniques can play a crucial role in overcoming this challenge.

- Combined Impact: These challenges often work together in a vicious cycle. Declining reservoir pressure necessitates artificial lift, which adds cost. High water cut further reduces well productivity. Aging infrastructure increases maintenance needs and potential downtime. All these factors contribute to a decline in overall field profitability. Well intervention strategies offer a powerful solution to address these challenges and revitalize mature fields, extending their productive life and maximizing their value.

Well Intervention Strategies in Mature Fields

Mature fields present unique challenges, but well intervention offers a diverse toolbox to address them. Here’s a deeper dive into the key intervention techniques and how they can be tailored for maximum impact:

Identification Techniques

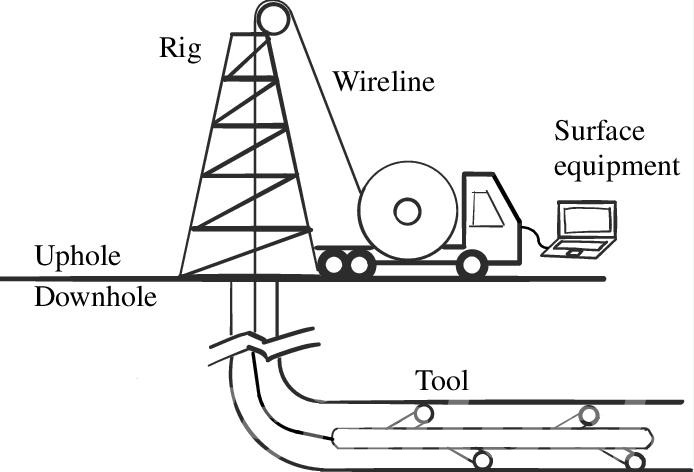

- Production Logging: This workhorse technique utilizes downhole tools with sensors that measure pressure, temperature, fluid flow rates, and fluid properties (like water cut) at various depths within the wellbore. This detailed data helps pinpoint zones with high water cut, bypassed oil pockets, or restrictions in flow.

- Reservoir Pressure Testing: By strategically placing pressure gauges downhole and analyzing pressure variations over time, engineers can determine areas of pressure depletion within the reservoir. This information is crucial for identifying zones that could benefit from pressure support methods or infill drilling to access untapped resources.

- 4D Seismic: Take a 3D seismic image of your reservoir, then capture another one a few years later. 4D seismic does exactly that, allowing operators to compare seismic data acquired over time. This comparison helps visualize changes in the reservoir, such as fluid movement and pressure variations. By identifying areas where fluids have migrated or pressure has declined, engineers can target intervention strategies to those specific zones, maximizing their impact.

Intervention Techniques

- Workovers: This is the “hands-on” approach, where a rig is brought in to access the wellbore directly. Depending on the specific challenges identified, workover techniques can involve:

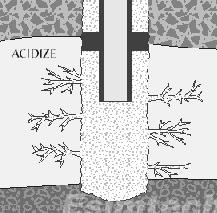

- Acidizing: Injecting acidic solutions to dissolve scale buildup within the wellbore or formation, improving flow paths for oil and gas.

- Fracturing: Creating controlled fractures in the rock formation to enhance its permeability, allowing oil and gas to flow more freely towards the wellbore.

- Wellbore Cleanouts: Removing debris, sand, or paraffin deposits that can restrict flow within the wellbore.

- Installing or Replacing Downhole Equipment: This could involve replacing worn-out pumps, valves, or packers to optimize well performance.

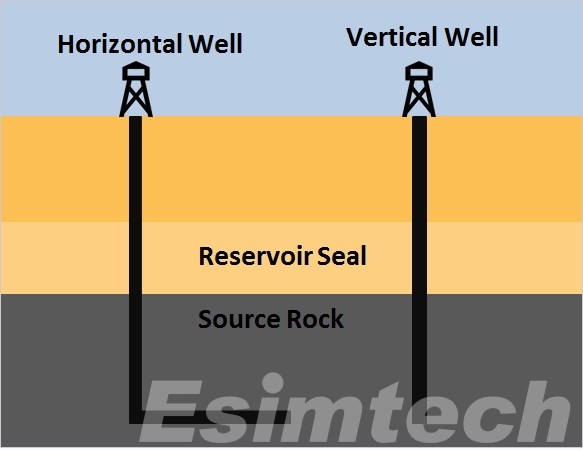

- Infill Drilling: Mature fields may have bypassed zones with untapped oil reserves due to limitations in technology or understanding of the reservoir during initial development. Infill drilling involves strategically drilling new wells within the existing field to target these bypassed zones or enhance drainage from poorly performing areas.

- Artificial Lift Optimization: As reservoir pressure declines in mature fields, artificial lift systems become crucial for bringing oil and gas to the surface. Well intervention strategies can involve upgrading existing lift systems (like gas lift or electrical submersible pumps) to handle higher volumes or replacing them with more efficient technologies.

Optimizing Intervention Strategies

Data and planning are key to maximizing the effectiveness of well intervention. Here’s how operators can optimize their strategies:

- Reservoir Simulation Software: By feeding the data gathered from identification techniques into reservoir simulation tools, engineers can model different intervention scenarios. These simulations predict the impact of various workover techniques, infill drilling locations, or artificial lift upgrades on production rates and overall field recovery.

- Cost-Benefit Analysis: No intervention strategy is worthwhile if the cost outweighs the benefits. A thorough cost-benefit analysis is crucial for selecting the most economically viable approach. This analysis should consider the cost of the intervention itself, the projected increase in production, and the expected lifespan extension of the field.

- Advanced Data Analytics: The vast amount of data collected from production logging, pressure testing, and 4D seismic can be overwhelming. Advanced data analytics tools can help identify patterns, trends, and anomalies within this data, leading to more precise targeting of intervention efforts and a higher chance of success.

Benefits of Well Intervention in Mature Fields

Well intervention offers numerous benefits that are crucial for the management and optimization of mature fields.

- Enhanced Production: One of the primary advantages of well intervention is the ability to restore or increase production rates. Techniques such as hydraulic fracturing, chemical stimulation, and mechanical repairs target specific problems within the wellbore, enhancing the flow of hydrocarbons. By addressing blockages, removing water or gas ingress, and repairing damaged equipment, operators can significantly boost production.

- Extended Field Life: Regular well intervention ensures that wells remain operational and productive for longer periods. By proactively maintaining and upgrading well infrastructure, operators can delay the decline in production typically associated with aging fields. This extends the economic viability of the field, allowing operators to maximize the recovery of hydrocarbons and defer the decommissioning process.

- Cost Efficiency: While well intervention activities involve initial expenditures, they can lead to substantial long-term savings. Preventive interventions mitigate the risk of major failures and avoid costly workovers. For instance, coiled tubing operations and targeted chemical treatments are often more cost-effective than full-scale drilling operations. By optimizing well performance, operators can achieve a higher return on investment.

- Environmental Protection: Effective well intervention plays a key role in minimizing environmental risks. By ensuring the integrity of wellbore equipment and preventing leaks or spills, operators can safeguard surrounding ecosystems. Additionally, improved production efficiency means less waste and reduced emissions per unit of oil or gas extracted, contributing to more sustainable operations.

In summary, well intervention in mature fields is integral to enhancing production, extending field life, achieving cost efficiency, and protecting the environment. As technology advances, these benefits will only grow, ensuring the sustained viability and profitability of mature oil and gas fields.

Conclusion

Well intervention is a critical tool for operators to unlock the full potential of mature oil and gas fields. By employing a combination of identification and intervention techniques, alongside data-driven planning, mature fields can be revitalized, extending their productive life and contributing significantly to overall oil and gas production.