Well Completion in Offshore and Deepwater Environments

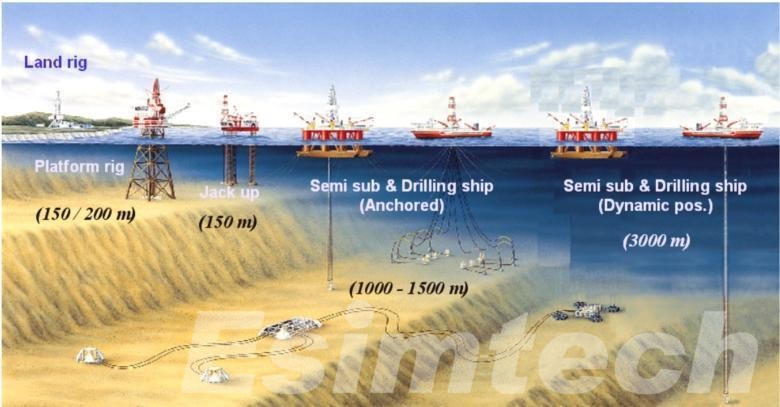

Well completion in offshore and deepwater environments is a critical phase in the lifecycle of an oil and gas well. This process involves preparing the well to produce hydrocarbons efficiently and safely, while also ensuring the structural integrity and environmental protection required in these challenging conditions. As exploration and production extend into deeper waters, the complexities and technological demands of well completion increase significantly. This article delves into the challenges, technologies, and best practices involved in offshore and deepwater well completion.

Challenges in Offshore and Deepwater Well Completion

Here’s a chart outlining the challenges in offshore and deepwater well completion

| Category | Challenges | Details |

| Environmental Conditions | Harsh Conditions Weather and Accessibility | High pressures, low temperatures, and corrosive environments affect equipment integrity and safety. Adverse weather can limit access and operational windows, complicating logistics and increasing costs. |

| Geological Complexity | Unpredictable Geology Reservoir Characterization | Complex and less predictable geological formations require tailored solutions for each well. Accurate assessment of deepwater reservoirs is challenging, affecting drilling and completion strategies. |

| Logistics and Infrastructure | Remote Locations Supply Chain Management | Transporting equipment, personnel, and supplies is time-consuming and costly. Ensuring timely delivery and maintenance of equipment is critical and challenging. |

| Safety and Environmental Risks | Blowouts and Spills Environmental Impact | Potential for blowouts and oil spills necessitates stringent safety protocols and reliable well control measures. Ensuring environmental protection and compliance with regulations is crucial to avoid ecological damage. |

| Technical Challenges | Equipment Reliability Advanced Technology Implementation | Equipment must withstand extreme conditions and perform reliably over extended periods. Integrating and managing advanced technologies such as subsea systems and intelligent completions. |

| Cost and Economic Factors | High Operational Costs Economic Viability | Offshore and deepwater operations are significantly more expensive than onshore operations. Ensuring the economic viability of projects in challenging environments is a key concern. |

| Regulatory and Compliance | Stringent Regulations Permitting and Licensing | Adhering to strict regulatory standards for safety, environmental protection, and operational procedures. Obtaining necessary permits and licenses can be a complex and lengthy process. |

Advanced Technologies for Offshore and Deepwater Well Completion

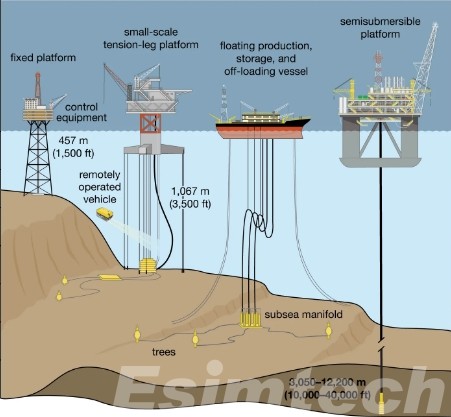

1. Subsea Well Completion Systems

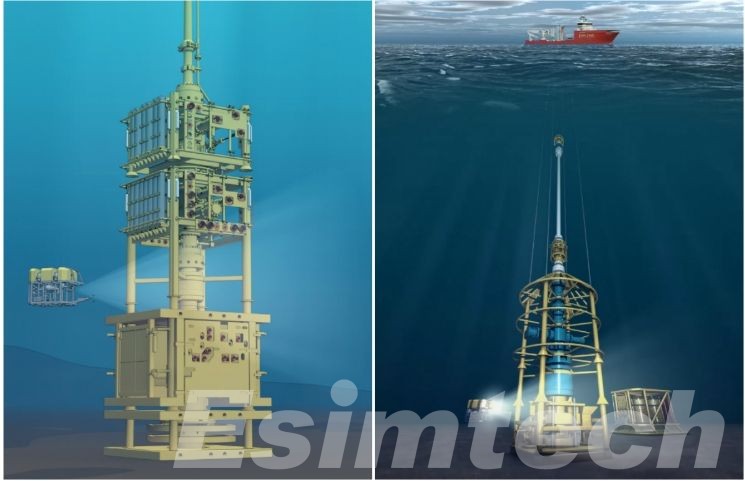

Subsea well completion systems are integral to deepwater operations, where wells are often located far from shore and at significant water depths. These systems include subsea trees, manifolds, and control systems, which are installed on the seabed.

- Subsea Trees: Subsea trees are used to control the flow of hydrocarbons from the well. They are equipped with valves and sensors to manage and monitor the production process remotely.

- Subsea Manifolds: Manifolds consolidate the flow from multiple wells and direct it to a central processing facility. This reduces the need for extensive surface infrastructure.

- Control Systems: Advanced control systems enable remote operation and monitoring of subsea equipment, providing real-time data and enhancing operational efficiency.

2. High-Pressure, High-Temperature (HPHT) Technologies

Deepwater wells often encounter high-pressure, high-temperature (HPHT) conditions, which necessitate specialized equipment and materials capable of withstanding these extremes.

- HPHT Completions: HPHT-rated completion tools and equipment are designed to operate reliably under extreme conditions. This includes packers, tubing, and casing that can withstand high pressures and temperatures.

- Advanced Materials: The use of corrosion-resistant alloys and high-strength materials ensures the durability and integrity of completion components in HPHT environments.

3. Intelligent Completions

Intelligent completions integrate advanced monitoring and control technologies within the wellbore, providing operators with real-time data on well performance and conditions.

- Downhole Sensors: Sensors placed along the wellbore measure pressure, temperature, and flow rates, transmitting data to the surface for analysis.

- Remote Control Devices: These devices allow operators to adjust valves and other completion components remotely, optimizing production and maintaining well integrity.

- Data Analytics: Real-time data analytics enable predictive maintenance and decision-making, improving overall well performance and reducing downtime.

4. Enhanced Cementing Techniques

Proper cementing is crucial for ensuring zonal isolation and maintaining well integrity, particularly in deepwater wells.

- Advanced Cement Formulations: Specialized cement blends are designed to set and bond effectively in high-pressure, low-temperature conditions.

- Cement Placement Techniques: Innovative techniques, such as foamed cement and cement expanders, improve the placement and bonding of cement, ensuring a strong seal and preventing fluid migration.

5. Remote Monitoring and Control

Remote monitoring and control systems are essential for managing deepwater wells, where direct access is often limited.

- Real-Time Monitoring: Continuous monitoring systems provide real-time data on well conditions, enabling prompt detection of anomalies and swift response to potential issues.

- Automation and Robotics: Automated systems and robotic technologies are increasingly used to perform complex tasks, such as valve adjustments and equipment inspections, enhancing safety and efficiency.

6. Multilateral Completions

Multilateral completions involve drilling multiple lateral branches from a single main wellbore, increasing reservoir contact and enhancing production.

- TAML (Technology Advancement for Multilaterals): TAML levels define the complexity and capability of multilateral completions, with higher levels indicating more sophisticated and integrated systems.

- Advanced Junction Designs: Robust junctions between the main wellbore and lateral branches ensure reliable isolation and flow control, maximizing production efficiency.

7. Advanced Stimulation Techniques

Stimulation techniques are used to enhance the flow of hydrocarbons from the reservoir to the wellbore, particularly in challenging deepwater formations.

- Hydraulic Fracturing: Multi-stage hydraulic fracturing involves injecting fluids at high pressures to create fractures in the reservoir rock, increasing permeability and flow rates.

- Acid Stimulation: Acidizing techniques dissolve formation damage and improve reservoir connectivity, enhancing production from carbonate reservoirs.

Best Practices for Well Completion in Offshore and Deepwater Environments

1. Thorough Planning and Risk Assessment

Comprehensive planning and risk assessment are fundamental to successful well completion in offshore and deepwater environments. This includes detailed geological analysis, environmental impact studies, and contingency planning for potential hazards.

2. Collaboration and Expertise

Collaboration among operators, service companies, and regulatory bodies is essential to address the unique challenges of deepwater completion. Leveraging the expertise of specialized teams ensures the application of best practices and innovative solutions.

3. Robust Well Control Measures

Implementing reliable well control measures, such as blowout preventers (BOPs) and advanced pressure management systems, is crucial to prevent blowouts and ensure the safety of personnel and the environment.

4. Environmental Stewardship

Adhering to environmental regulations and adopting best practices for environmental protection is vital in offshore and deepwater operations. This includes minimizing the impact of drilling and completion activities on marine ecosystems.

5. Continuous Improvement and Innovation

The offshore and deepwater sectors are continually evolving, driven by technological advancements and lessons learned from previous operations. Continuous improvement and innovation are key to overcoming challenges and enhancing the efficiency and safety of well completion.

How Simulations are Used in Various Stages of Offshore and Deepwater Well Completion

1. Reservoir Modeling and Simulation

Reservoir Characterization

- Objective: Understand the reservoir’s geological and petrophysical properties.

- Tools: Seismic data, well logs, core samples, and geostatistical methods.

- Simulations: Generate 3D reservoir models to predict the distribution of hydrocarbons, porosity, permeability, and other key parameters.

Dynamic Reservoir Simulation

- Objective: Predict fluid flow and reservoir performance over time.

- Tools: Finite difference and finite element simulators.

- Simulations: Model multiphase flow of oil, gas, and water; assess the impact of production strategies on reservoir behavior; optimize production rates and recovery methods.

2. Wellbore Stability and Drilling Simulations

Wellbore Stability Analysis

- Objective: Ensure wellbore integrity during drilling and completion.

- Tools: Geomechanical models, well logs, and real-time drilling data.

- Simulations: Predict stress distribution, pore pressure, and rock strength to identify safe mud weights and avoid wellbore collapse or fracturing.

Drilling Fluid Optimization

- Objective: Select the optimal drilling fluid composition.

- Tools: Hydraulics modeling software.

- Simulations: Assess fluid rheology, cuttings transport efficiency, and the potential for wellbore stability issues.

3. Hydraulic Fracturing Simulations

Fracture Design and Optimization

- Objective: Design effective hydraulic fracturing treatments to enhance reservoir connectivity.

- Tools: Fracture propagation models, reservoir simulators.

- Simulations: Model fracture growth, fluid and proppant placement, and the interaction with natural fractures; optimize fracture dimensions and stages to maximize hydrocarbon flow.

4. Completion Design and Performance Simulations

Completion Equipment and Configuration

- Objective: Design and optimize well completion hardware and techniques.

- Tools: Well completion design software.

- Simulations: Analyze the performance of completion equipment such as packers, tubing, and sand control devices under various operational conditions.

Flow Assurance Modeling

- Objective: Ensure reliable flow of hydrocarbons from the reservoir to the surface.

- Tools: Flow assurance simulators.

- Simulations: Predict issues like hydrate formation, wax deposition, and scale buildup; design mitigation strategies such as insulation, chemical injection, and heating.

5. Well Integrity and Cementing Simulations

Cementing Design and Evaluation

- Objective: Achieve effective zonal isolation and well integrity.

- Tools: Cementing software, fluid dynamics models.

- Simulations: Model cement slurry placement, displacement efficiency, and curing process; predict the long-term integrity of cement bonds and identify potential weak spots.

Well Integrity Monitoring

- Objective: Ensure long-term well integrity and prevent leaks.

- Tools: Integrity management software, real-time monitoring systems.

- Simulations: Assess the impact of thermal and pressure cycles on wellbore integrity; model the performance of barriers and seals under various scenarios.

6. Production Optimization Simulations

Production Forecasting

- Objective: Predict and optimize well production performance.

- Tools: Integrated asset modeling software.

- Simulations: Model the entire production system, from the reservoir through the wellbore to surface facilities; identify bottlenecks and optimize lift methods and surface equipment.

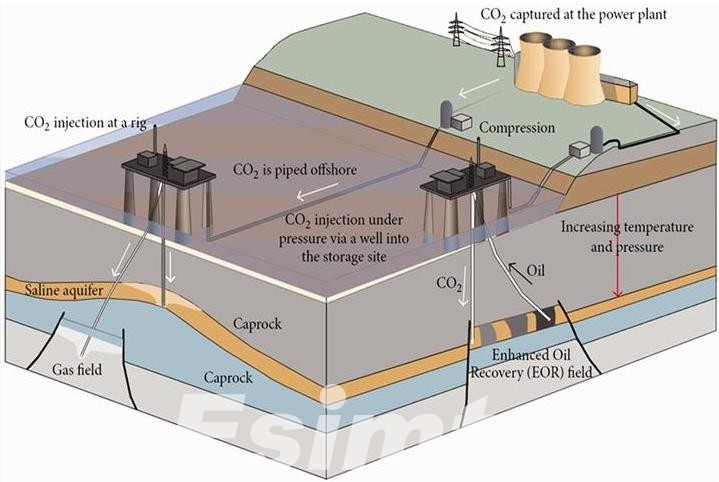

Enhanced Oil Recovery (EOR) Simulations

- Objective: Evaluate and design EOR techniques to improve recovery rates.

- Tools: Reservoir simulators with EOR modules.

- Simulations: Model the injection of fluids like water, gas, or chemicals; predict the impact on reservoir pressure and fluid displacement efficiency.

Conclusion

Well completion in offshore and deepwater environments is a complex and demanding process that requires advanced technologies, meticulous planning, and adherence to best practices. The development of innovative solutions and a commitment to safety and environmental stewardship will be essential to ensuring the success and sustainability of offshore and deepwater well completions.

Various simulations help engineers and geoscientists understand complex subsurface conditions, optimize completion designs, and mitigate risks associated with drilling and production.