Well Cementing in Unconventional Environments

Well cementing is a critical process in oil and gas drilling, ensuring the integrity and stability of wells. This process becomes even more challenging in unconventional environments such as deepwater, shale formations, and high-temperature high-pressure reservoirs, where traditional techniques may not suffice, requiring specialized well cementing strategies.

What is Well Cementing

| Aspect | Description |

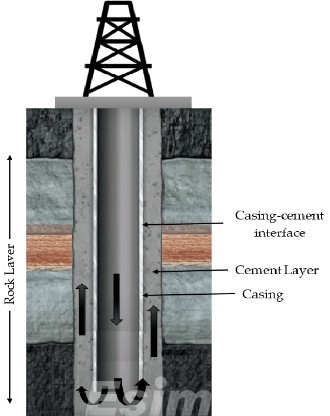

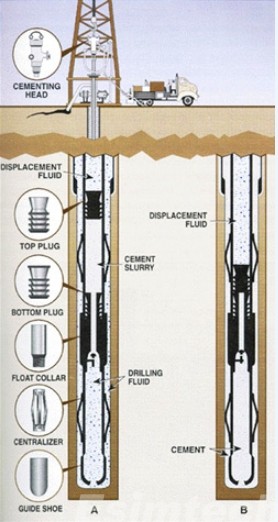

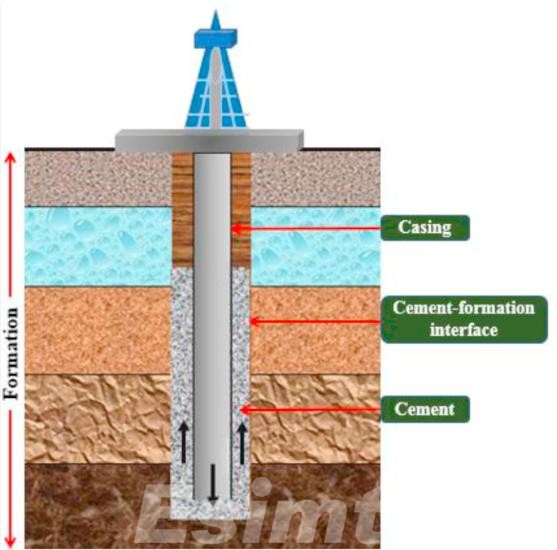

| Definition | The process of placing cement in the annular space between the wellbore and casing to seal the well. |

| Primary Objectives | – Provide zonal isolation – Support and protect the casing – Prevent fluid migration |

| Types of Cementing | – Primary Cementing: Initial cement placement to seal casing. – Remedial Cementing: Fixes issues like leaks or damaged casing. |

| Cement Slurry Composition | A mixture of cement, water, and additives tailored to meet specific well conditions. |

| Additives | – Retarders: Slow down setting time – Accelerators: Speed up setting time – Fluid-loss additives: Prevent fluid migration |

Understanding Unconventional Environments for Well Cementing

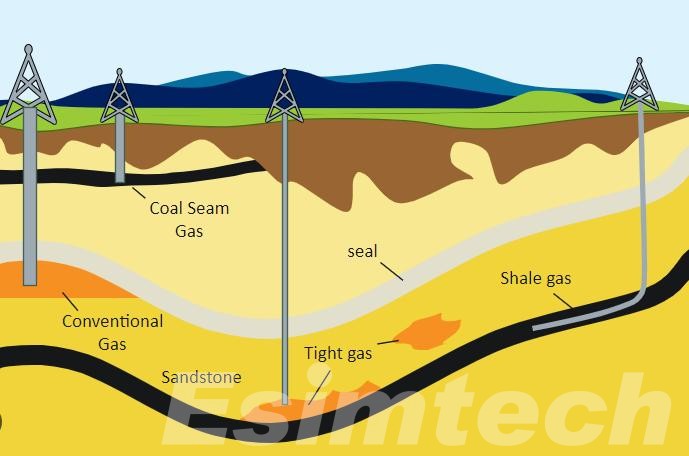

Unconventional environments refer to geological settings where extracting oil and gas is more challenging due to factors like extreme depths, high pressures, low permeability formations, or unusual reservoir characteristics. These environments often include:

- Shale Formations: Characterized by low permeability, requiring hydraulic fracturing to extract hydrocarbons.

- Deepwater Reservoirs: Located beneath deep ocean waters, posing challenges related to high pressure, low temperatures, and remote locations.

- High-Temperature High-Pressure (HTHP) Reservoirs: Found in deeper formations with extreme temperatures and pressures that exceed conventional limits.

Each of these environments requires a tailored approach to well cementing to ensure the long-term integrity of the well.

Challenges Associated with Well Cementing in Unconventional Environments

Well cementing in unconventional environments presents a unique set of challenges that differ significantly from those encountered in conventional oil and gas drilling operations.

1. Extreme Pressure and Temperature

- High-Pressure Environments: Unconventional reservoirs, particularly those classified as high-pressure high-temperature (HTHP), can exhibit pressures that far exceed those encountered in conventional wells. Cement used in these environments must be able to withstand extreme downhole pressures without compromising its structural integrity.

- High-Temperature Conditions: In HTHP wells, temperatures can exceed 300°F (150°C). Such conditions can lead to thermal degradation of the cement, causing it to lose strength over time. The cement slurry must be carefully formulated with temperature-resistant additives to prevent strength retrogression and ensure long-term stability.

2. Fluid Migration and Zonal Isolation

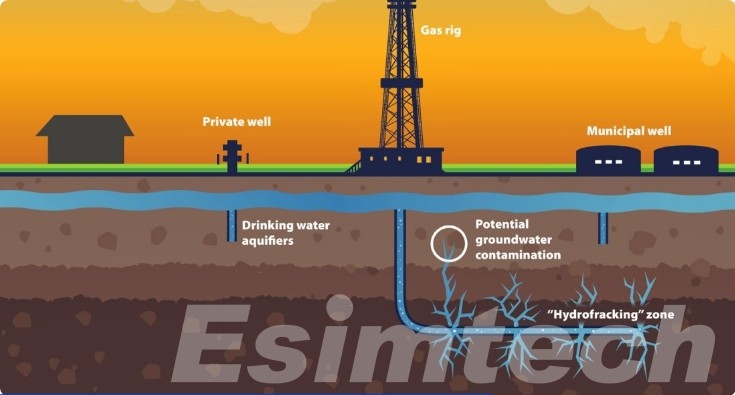

- Shale Formations: Shale formations are characterized by low permeability, which complicates the process of achieving effective zonal isolation. Improper cementing can lead to fluid migration, where gas or liquid can seep through the cement and enter other zones or the surface, leading to environmental hazards and compromised well integrity.

- Gas Migration: In unconventional reservoirs, particularly in shale gas plays, the risk of gas migration is significant. Gas migration occurs when gas enters the cement column before it sets, leading to channels or pathways that can compromise zonal isolation. This issue is exacerbated in low-permeability formations where maintaining a gas-tight seal is critical.

3. Deepwater Challenges

- Low Temperatures: In deepwater environments, the low temperatures at the seabed can slow down the setting time of cement, increasing the risk of cement slurry contamination or failure. Cement must be designed to set properly at low temperatures while maintaining the necessary strength.

- Hydrostatic Pressure: Deepwater wells are subjected to high hydrostatic pressures due to the depth of the water column. These pressures can cause challenges in balancing the cement density to avoid issues like lost circulation or improper sealing.

- Logistical and Operational Complexities: Deepwater operations are often located far from shore, making it difficult to deliver materials and equipment in a timely manner. The remoteness of these locations also complicates the cementing process, as any issues that arise can be challenging to address quickly.

4. Fracture-Induced Stress

- Hydraulic Fracturing: In shale formations, hydraulic fracturing is commonly used to stimulate production. However, the process introduces significant stress on the wellbore and cement, which can lead to the formation of microannuli or cracks in the cement sheath. These issues can compromise the seal, leading to potential well integrity problems.

- Cement Durability: The repeated cycles of pressure and stress from hydraulic fracturing require cement that can withstand these conditions without degrading. The cement must be durable and resilient, maintaining its seal under the harsh mechanical conditions of fracturing operations.

5. Material Selection and Compatibility

- Additive Compatibility: The selection of additives in the cement slurry is crucial in unconventional environments. Additives must be carefully chosen to enhance properties such as temperature resistance, flexibility, and strength. However, incompatibility between different additives can lead to issues like delayed setting times or reduced cement strength.

- Cement-Slurry Design: Designing the right cement slurry for unconventional environments is a complex task. The slurry must be tailored to the specific conditions of the well, taking into account factors like pressure, temperature, fluid type, and formation characteristics. Errors in slurry design can lead to poor cementing outcomes and compromised well integrity.

6. Environmental and Regulatory Compliance

- Stricter Regulations: Unconventional environments, particularly those in sensitive or remote areas, are often subject to stringent environmental regulations. Ensuring that cementing operations meet these regulatory requirements while maintaining well integrity is a significant challenge.

- Risk of Contamination: The potential for environmental contamination is higher in unconventional wells, particularly in deepwater or shale gas operations. Cementing must be done with extreme care to prevent any leakage of hydrocarbons into surrounding environments.

Innovative Solutions for Well Cementing in Unconventional Environments

To address these challenges, the oil and gas industry has developed a range of innovative solutions that enhance the effectiveness of well-cementing in these demanding settings.

1. Advanced Cement Slurries

- High-Temperature Resistant Cement: In HTHP environments, standard cement can degrade due to extreme heat and pressure. To combat this, high-temperature-resistant cements have been developed. These cements often include additives such as silica flour, which helps maintain strength and prevent strength retrogression at elevated temperatures. Additionally, retarders are used to control the setting time, ensuring that the cement can be properly placed before it hardens.

- Flexible and Elastic Cements: Unconventional wells, particularly in shale formations where hydraulic fracturing is used, require cement that can withstand mechanical stress without cracking. Flexible and elastic cement are formulated to accommodate the expansion and contraction of the wellbore during production and fracturing operations. These cement reduce the risk of micro annuli formation, which can lead to gas migration and loss of well integrity.

- Lightweight Cement for Deepwater: In deepwater environments, high hydrostatic pressures can cause issues like lost circulation if the cement is too dense. Lightweight cements, often enhanced with microspheres or other low-density materials, provide a solution. These cements reduce the overall density of the slurry, helping to balance the pressure and prevent loss of circulation while still providing a robust seal.

2. Expandable Casing Systems

Expandable casing systems are an innovative approach to enhancing well integrity in unconventional environments, especially in shale formations and deepwater wells. These systems involve a casing or liner that is expanded after being run into the wellbore, creating a tight seal against the formation.

- Improved Zonal Isolation: The expansion process ensures a close fit between the casing and the wellbore, reducing the risk of fluid migration and ensuring effective zonal isolation. This is particularly important in shale formations, where maintaining a gas-tight seal is critical.

- Reduced Casing Diameter: Expandable casing systems can also reduce the overall diameter of the well, which is beneficial in deepwater drilling where space and weight are limited. This allows for more efficient well designs and can reduce drilling costs.

3. Self-Healing Cements

Self-healing cement represents a major advancement in ensuring long-term well integrity, particularly in environments prone to stress and mechanical failures.

- Autonomous Healing Mechanism: These cement contain materials that can react with water or other well fluids to form a solid plug in the event of a crack or micro annulus formation. This autonomous healing process prevents the formation of pathways that could allow gas or fluid migration, maintaining the integrity of the cement sheath over the life of the well.

- Enhanced Longevity: By automatically sealing any small cracks that may develop over time, self-healing cements extend the life of the well and reduce the need for costly remedial operations.

4. Real-Time Monitoring and Diagnostics

The use of real-time monitoring and diagnostic tools has revolutionized the well cementing process, particularly in unconventional environments where conditions can change rapidly.

- Acoustic and Ultrasonic Tools: These tools allow operators to monitor the cementing process in real time, providing valuable data on the placement and quality of the cement. Acoustic tools can detect the presence of gas in the cement slurry, while ultrasonic tools can measure the bond strength between the cement and the casing or formation.

- Real-Time Adjustments: With real-time data, operators can make adjustments on the fly, such as altering the pump rate or adjusting the slurry composition, to ensure a successful cement job. This is particularly important in deepwater or HTHP environments, where conditions can be unpredictable.

5. Nanotechnology-Enhanced Cements

Nanotechnology is being increasingly applied to enhance the properties of cement used in unconventional environments.

- Improved Strength and Durability: Nanoparticles, such as nano silica, can be added to cement to improve its mechanical properties, including compressive strength and durability. These enhancements are particularly beneficial in HTHP environments where cement needs to withstand extreme conditions.

- Enhanced Flow Properties: Nanoparticles can also improve the flow properties of cement slurry, allowing for better placement in complex well geometries or in formations with low permeability. This ensures a more uniform and effective seal around the wellbore.

6. Customizable Cementing Solutions

Given the variability of conditions in unconventional environments, customizable cementing solutions have become essential.

- Tailored Cement Slurries: Customizable cement slurries are designed based on the specific conditions of each well, taking into account factors such as temperature, pressure, formation properties, and the presence of corrosive fluids. This level of customization ensures that the cement will perform optimally in its intended environment.

- Integrated Design Software: Advanced software tools are used to model the well conditions and design the cement slurry accordingly. These simulation tools are used for modeling the downhole environment and predicting how the cement will behave, allowing for more precise and effective cementing operations.

In summary, well cementing in unconventional environments is a complex and challenging task that requires specialized solutions to ensure the integrity and safety of oil and gas wells. The development and application of advanced cementing technologies will be crucial in overcoming the unique challenges presented by these environments.