Understanding Reservoir Geomechanics for Optimizing Hydrocarbon Recovery

Reservoir geomechanics integrates principles from geology, geophysics, and engineering and provides insights into the mechanical behavior of subsurface formations. It is vital for optimizing hydrocarbon recovery, managing risks, and ensuring the long-term wellbore stability, important in the exploration, development, and production of oil and gas reservoirs.

What is Reservoir Geomechanics

Reservoir geomechanics focuses on the study of how rocks in a reservoir respond to changes in stress, pressure, and temperature. These changes can be induced by natural processes or human activities such as drilling, hydraulic fracturing, and fluid injection. The field encompasses several key areas, including stress analysis, rock mechanics, fault and fracture characterization, and the prediction of subsurface behavior.

Key Concepts in Reservoir Geomechanics

1. In-Situ Stress State

The in-situ stress state refers to the natural stresses present in the Earth’s crust before any human activities such as drilling or production. These stresses are typically categorized into three principal stresses: vertical stress, maximum horizontal stress, and minimum horizontal stress.

Importance: Understanding the in-situ stress state is crucial for predicting rock deformation, fault reactivation, and wellbore stability. It influences decisions regarding well placement, drilling direction, and hydraulic fracturing operations.

2. Rock Mechanics

Rock mechanics deals with the mechanical properties of reservoir rocks, such as their strength, elasticity, porosity, and permeability. It also involves studying how rocks respond to stress, temperature, and pressure changes.

Elasticity and Plasticity: Rocks can behave elastically, returning to their original shape after the stress is removed, or plastically, where they undergo permanent deformation. The study of rock mechanics helps in assessing the potential for reservoir compaction, subsidence, and wellbore collapse.

3. Pore Pressure

Pore pressure is the pressure exerted by fluids within the pores of a rock. It is a critical factor in determining the effective stress on a rock, which in turn influences its mechanical behavior.

Overpressure: In some reservoirs, abnormally high pore pressure, known as overpressure, can pose challenges during drilling and production. Managing pore pressure is essential for preventing well blowouts and ensuring wellbore stability.

4. Effective Stress

Effective stress is the difference between the total stress acting on a rock and the pore pressure within it. It is the stress that actually contributes to rock deformation and failure.

Significance: Understanding effective stress is important for predicting subsurface behavior during activities such as hydraulic fracturing, fluid injection, and production. It helps in assessing the risk of rock failure and optimizing reservoir management strategies.

5. Faults and Fractures

Faults and fractures are natural or induced discontinuities in the rock mass that can significantly impact fluid flow and reservoir integrity.

Fault Reactivation: Changes in stress or pressure due to production activities can reactivate pre-existing faults, leading to seismic events or fluid leakage. Geomechanical models help assess the risk of fault reactivation and guide safe reservoir management practices.

6. Wellbore Stability

Wellbore stability refers to the condition of the borehole as it is drilled and during production. It is influenced by the surrounding rock’s mechanical properties, in-situ stress state, and drilling parameters.

Mud Weight Design: Proper mud weight design is essential for balancing pore pressure and supporting the wellbore walls. Too low a mud weight can lead to wellbore collapse, while too high a mud weight can fracture the formation.

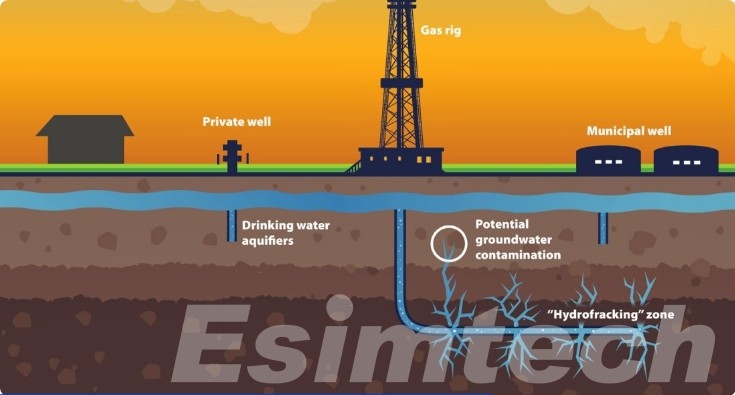

7. Hydraulic Fracturing

Hydraulic fracturing involves injecting fluids at high pressure to create fractures in the rock, enhancing fluid flow and increasing hydrocarbon production.

Fracture Propagation: Understanding how fractures propagate, interact with existing faults, and affect reservoir behavior is key to optimizing hydraulic fracturing operations and improving recovery rates.

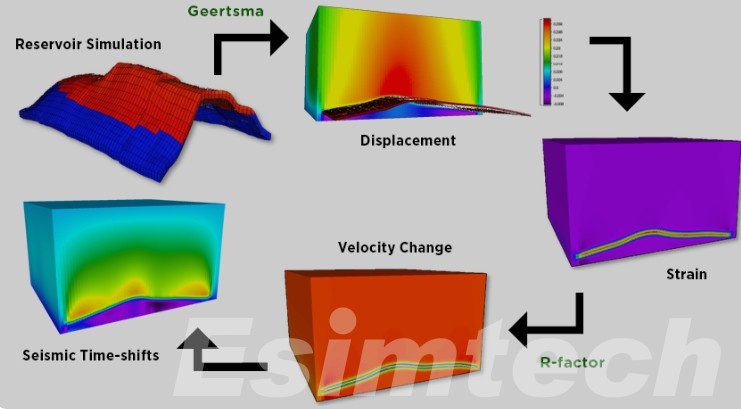

8. Reservoir Compaction and Subsidence

Reservoir compaction occurs when pore pressure decreases, leading to the collapse of pore spaces and a reduction in rock volume. This can cause surface subsidence, which may impact infrastructure.

Monitoring: Geomechanical models are used to predict and monitor compaction and subsidence, enabling proactive management to minimize environmental and operational risks.

9. Seismicity

Seismicity refers to the occurrence of earthquakes or tremors caused by the reactivation of faults due to changes in stress or pressure within the reservoir.

Induced Seismicity: Activities like fluid injection, gas storage, or geothermal energy production can induce seismic events. Geomechanics helps in assessing and mitigating these risks to ensure safe operations.

Applications of Reservoir Geomechanics

Here’s a chart outlining the diverse applications of reservoir geomechanics across various industries, emphasizing its critical role in optimizing resource extraction, ensuring safety, and minimizing environmental impact in the oil and gas drilling operations.

| Application | Description | Key Benefits | Relevant Industries |

| Wellbore Stability Analysis | Assessing and managing the stability of the wellbore during drilling and production | Prevents wellbore collapse, reduces non-productive time | Oil & Gas, Geothermal Energy |

| Hydraulic Fracturing Design | Optimizing fracture initiation, propagation, and network development | Enhances hydrocarbon recovery, reduces environmental risks | Unconventional Reservoirs, Shale Gas |

| Reservoir Compaction and Subsidence | Monitoring and predicting reservoir compaction and surface subsidence due to fluid extraction | Protects surface infrastructure, ensures long-term reservoir stability | Oil & Gas, CO2 Sequestration |

| Pore Pressure Prediction and Management | Estimating and controlling pore pressure during drilling, production, and injection operations | Prevents blowouts, enhances well control | Oil & Gas, Geothermal Energy |

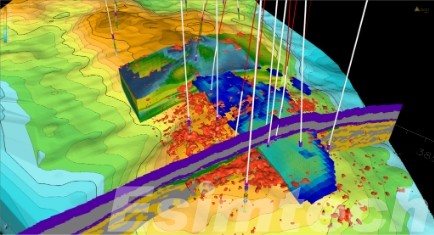

| Fault and Fracture Characterization | Identifying and assessing faults and fractures that may impact fluid flow and reservoir integrity | Improves reservoir management, reduces risk of seismicity | Oil & Gas, Geothermal Energy |

| Induced Seismicity Risk Assessment | Evaluating the potential for human activities to induce seismic events | Ensures safe operations, minimizes environmental impact | Oil & Gas, Geothermal Energy, CO2 Sequestration |

| Enhanced Oil Recovery (EOR) | Using geomechanical insights to optimize EOR techniques such as waterflooding and CO2 injection | Maximizes hydrocarbon recovery, optimizes injection strategies | Oil & Gas, CO2 Sequestration |

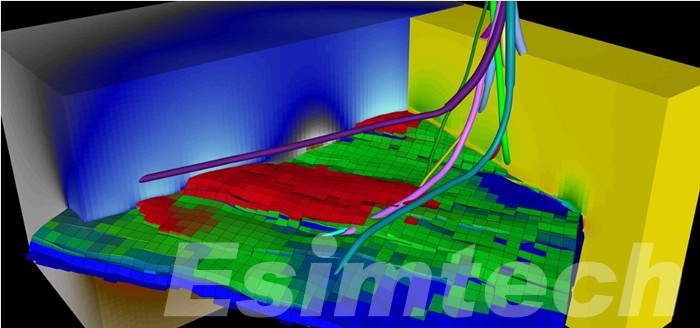

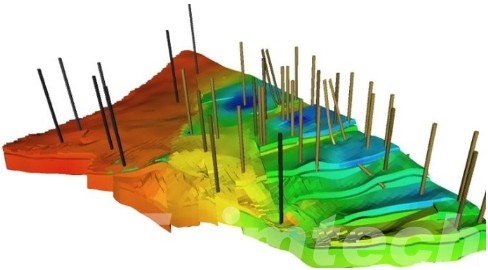

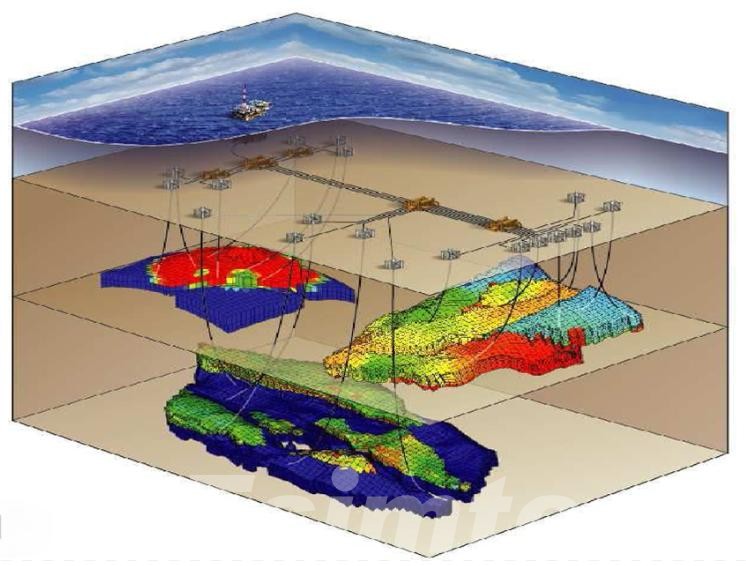

| Reservoir Management and Simulation | Integrating geomechanical models with reservoir simulations to predict long-term reservoir behavior | Optimizes production strategies, extends reservoir life | Oil & Gas |

| Geothermal Energy Development | Assessing geomechanical conditions for safe and efficient geothermal energy extraction | Increases energy recovery, ensures reservoir sustainability | Geothermal Energy |

| CO2 Sequestration and Storage | Evaluating and managing the geomechanical integrity of reservoirs used for long-term CO2 storage | Reduces risk of leakage, ensures environmental compliance | CO2 Sequestration |

Challenges and Future Directions in Reservoir Geomechanics

Reservoir geomechanics is vital in managing subsurface resources, particularly in the oil and gas industry. However, the field faces numerous challenges that require innovative solutions to ensure the safe and efficient extraction of hydrocarbons.

Challenges

1. Data Acquisition and Quality

- Challenge: Acquiring accurate, high-resolution geomechanical data from deep or complex reservoirs is difficult. Traditional methods like well logs and core samples provide limited information, leading to uncertainties in geomechanical models.

- Impact: Poor data quality can lead to inaccurate predictions of reservoir behavior, potentially causing issues such as wellbore instability, ineffective hydraulic fracturing, and unforeseen reservoir compaction.

2. Complex and Heterogeneous Reservoirs

- Challenge: Reservoirs often have complex geological features, including varying lithologies, fault networks, and anisotropic stress fields. Modeling these complex subsurface conditions accurately is challenging.

- Impact: Misinterpretation of the reservoir’s complexity can result in suboptimal drilling plans, inefficient hydrocarbon recovery, and unexpected geomechanical failures.

3. Induced Seismicity

- Challenge: Human activities such as fluid injection, hydraulic fracturing, and geothermal energy production can induce seismic events by altering subsurface stress conditions. Predicting and managing these events is complex due to the dynamic nature of subsurface environments.

- Impact: Induced seismicity can pose significant safety risks, leading to regulatory restrictions and public concern. It can also damage infrastructure and compromise reservoir integrity.

4. Wellbore Stability

- Challenge: Ensuring wellbore stability in challenging environments like deepwater, high-temperature/high-pressure (HPHT), and unconventional reservoirs is difficult due to the extreme conditions and complex stress states.

- Impact: Instability can lead to wellbore collapse, stuck pipes, and costly drilling delays, increasing non-productive time and operational risks.

5. Environmental and Regulatory Pressures

- Challenge: Increasing environmental regulations and public scrutiny require geomechanical solutions that minimize risks such as groundwater contamination, surface subsidence, and induced seismicity.

- Impact: Non-compliance with environmental standards can lead to project delays, increased costs, or even project shutdowns, impacting the overall feasibility of resource extraction.

6. Pore Pressure Prediction

- Challenge: Accurate prediction and management of pore pressure, especially in overpressured reservoirs, remain challenging due to the complexity of subsurface conditions.

- Impact: Incorrect pore pressure estimation can lead to well control problems, including blowouts, or inefficient production strategies.

Future Solutions

1. Advanced Data Acquisition Technologies

- Solution: The development of new sensors, real-time monitoring tools, and remote sensing technologies will improve the acquisition of high-resolution geomechanical data. Enhanced methods like fiber-optic sensing, microseismic monitoring, and satellite-based surface deformation tracking will provide more accurate and continuous data.

- Benefit: Improved data acquisition will lead to more accurate geomechanical models, reducing uncertainties and enhancing the predictability of reservoir behavior.

2. Machine Learning and AI-Driven Models

- Solution: Integrating machine learning and AI with geomechanics will enhance data processing, pattern recognition, and predictive modeling. These technologies can analyze large datasets, identify trends, and optimize reservoir management strategies in real time.

- Benefit: AI-driven models will improve the accuracy and efficiency of geomechanical predictions, enabling more informed decision-making and reducing the risk of operational failures.

3. Fully Coupled Multi-Physics Simulations

- Solution: Developing fully coupled simulation tools that integrate geomechanics with fluid flow, thermal, and chemical processes will provide a more holistic understanding of reservoir behavior. These simulations will account for the interplay between different physical processes in the reservoir.

- Benefit: Enhanced simulation tools will enable better predictions of reservoir performance, optimizing production strategies and minimizing risks associated with complex subsurface conditions.

Esimtech offers cutting-edge simulation tools covering a wide range of processes, including drilling, well control, and production operations. These tools provide a safe and controlled environment for users to gain hands-on experience, improving operational efficiency, and ensuring compliance with industry standards. Whether for educational institutions or industry training programs, Simulation tools provided by Esimtech are invaluable for developing the skills needed in today’s energy sector.

4. Real-Time Monitoring and Adaptive Operations

- Solution: Implementing real-time monitoring systems combined with adaptive operational strategies will allow for immediate adjustments based on subsurface conditions. Techniques such as real-time borehole stability monitoring and seismic event tracking will be critical.

- Benefit: Real-time monitoring will enhance operational safety, reduce the risk of induced seismicity, and ensure wellbore stability, particularly in challenging environments.

5. Sustainable and Environmentally Friendly Practices

- Solution: Future geomechanical practices will focus on sustainability, including minimizing the environmental footprint of subsurface activities. Innovations in carbon capture and storage (CCS), reduced subsurface disturbance techniques, and environmentally friendly drilling fluids will be essential.

- Benefit: Adopting sustainable practices will help meet regulatory requirements, reduce environmental impacts, and maintain social license to operate, ensuring the long-term viability of resource extraction projects.

6. Improved Pore Pressure Management

- Solution: Advancements in pore pressure prediction models, coupled with real-time monitoring technologies, will provide better control over subsurface pressures. The use of advanced drilling techniques and managed pressure drilling (MPD) systems will also help manage pore pressure more effectively.

- Benefit: Improved pore pressure management will prevent well control issues, enhance drilling efficiency, and optimize reservoir recovery.

Addressing the challenges in reservoir geomechanics requires a combination of advanced technologies, interdisciplinary collaboration, and a focus on sustainability.