Understanding Oil Rig Injuries: Causes, Consequences, and Preventive Measures

Oil rigs are essential components of the global energy industry, enabling the extraction of valuable fossil fuels that power our modern world. However, working on an oil rig is not without its risks. Oil rig injuries can have devastating consequences for workers and the environment. In this article, we will explore the common causes of oil rig injuries, their consequences, and preventive measures to ensure safer working conditions.

Common Causes of Oil Rig Injuries

Oil rig workers face a multitude of hazards on a daily basis. Understanding these risks is the first step towards preventing accidents and ensuring the safety of those who work in this demanding environment. Here are some of the common causes of oil rig injuries:

1. Slips, Trips, and Falls

Slippery surfaces, uneven walkways, and unpredictable weather conditions on oil rigs create an environment ripe for slips, trips, and falls. These seemingly mundane accidents can result in a wide range of injuries, from minor bruises and sprains to more severe head injuries and spinal cord damage. The proximity of the rig to the ocean exacerbates the danger, as a fall into the water can be life-threatening.

2. Machinery Accidents

Oil rigs are equipped with an array of heavy machinery and equipment crucial for drilling and extraction operations. While these machines are essential, they can also be dangerous if not operated and maintained properly. Accidents involving drilling equipment, cranes, and winches can lead to crush injuries, amputations, or, in the worst-case scenario, fatalities.

3. Fires and Explosions

The oil and gas industry deals with flammable materials and chemicals on a daily basis, making oil rigs susceptible to fires and explosions. These incidents can have catastrophic consequences, causing severe burns, smoke inhalation injuries, and, tragically, fatalities. The confined nature of an oil rig can make it extremely challenging to control and contain such emergencies.

4. Chemical Exposure

Oil rig workers are regularly exposed to a variety of chemicals used in drilling, maintenance, and production operations. Prolonged exposure or accidental spills can lead to chemical burns, respiratory problems, and long-term health issues. Chemical exposure not only affects the injured worker but can also contaminate the surrounding environment.

5. Falling Objects

Oil rig operations often involve work at considerable heights, whether on drilling platforms or while working on derricks and scaffolds. This height increases the risk of falling objects. Even seemingly small objects dropped from a significant height can cause serious injuries, including head trauma, fractures, and lacerations.

6. Weather-Related Incidents

Oil rigs are stationed in offshore environments, which are notorious for their unpredictable and often harsh weather conditions. Storms, high winds, and rough seas can lead to accidents, including vessel collisions and equipment damage. The inherent instability of working on the open water only magnifies the dangers associated with these weather-related incidents.

Consequences of Oil Rig Injuries

The consequences of oil rig injuries are far-reaching and affect not only the injured workers but also their families, colleagues, and the environment. Let’s explore these consequences in detail:

1. Physical Injuries

Oil rig injuries can result in a wide range of physical injuries, from minor cuts and bruises to life-altering conditions. Some of the most common physical injuries include:

- Fractures and Sprains: Falls and machinery accidents often lead to fractures, sprains, and strains, causing immense pain and discomfort to the injured worker.

- Head Injuries: Head injuries, such as concussions and traumatic brain injuries (TBIs), can occur due to falls, falling objects, or explosions. These injuries can have long-term cognitive and neurological effects.

- Burns: Fires and explosions can cause severe burns, which require extensive medical treatment and often result in disfigurement and scarring.

- Amputations: Machinery accidents can lead to traumatic amputations, forever altering a worker’s life and ability to perform their job.

- Spinal Cord Injuries: Falls from heights can result in spinal cord injuries, which may lead to paralysis and a lifetime of medical and rehabilitative care.

2. Emotional and Psychological Impact

Oil rig injuries can be traumatic events that have a profound emotional and psychological impact on affected workers. The isolation of working offshore, combined with the severity of the accidents, can lead to:

- Anxiety: Workers may experience heightened anxiety and fear, both during and after the accident, often stemming from concerns about their recovery and the ability to return to work.

- Depression: The physical pain, loss of livelihood, and isolation can contribute to feelings of hopelessness and depression among injured workers.

- Post-Traumatic Stress Disorder (PTSD): Experiencing a traumatic incident, such as an explosion or a near-death fall, can lead to PTSD, with flashbacks, nightmares, and severe anxiety.

- Substance Abuse: Some workers may turn to substance abuse as a coping mechanism, further exacerbating their emotional and psychological issues.

3. Financial Consequences

Oil rig injuries can have severe financial repercussions, both for the injured workers and their families. The financial strain can manifest in several ways:

- Medical Bills: Injured workers often face substantial medical bills, including hospitalization, surgeries, and ongoing rehabilitation.

- Lost Wages: Time off work due to injury means lost wages, which can lead to financial instability and hardships for the worker and their family.

- Reduced Earning Potential: Depending on the severity of the injury, workers may have to switch to less physically demanding roles or even find new career paths, resulting in a reduced earning potential.

- Family Impact: The financial burden can affect not only the injured worker but also their family, who may have to provide additional financial support during the recovery process.

4. Environmental Impact

In addition to human consequences, oil rig accidents can have severe environmental repercussions. Oil spills, chemical leaks, and other incidents can harm marine ecosystems and lead to long-term ecological damage. The fragile balance of marine life can be disrupted, affecting not only local wildlife but also the livelihoods of coastal communities dependent on fishing and tourism.

Preventive Measures of Oil Rig Injuries

Given the high stakes and potential for catastrophic consequences, the oil and gas industry has implemented a range of preventive measures to mitigate the risks associated with oil rig injuries. These measures are designed to ensure the safety of workers, protect the environment, and prevent accidents from occurring. Here are some of the key preventive measures:

1. Training and Education

Emergency Response Training

Simulators are instrumental in training workers to respond swiftly and effectively to emergencies, such as fires, explosions, or equipment failures. These simulations provide workers with the opportunity to practice their response without exposing them to real-world dangers, ensuring they are better prepared when a genuine emergency arises.

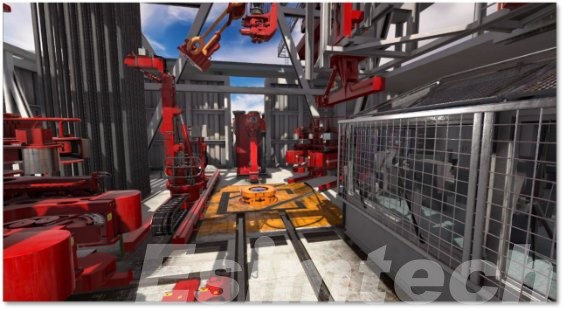

Drilling Operations

Drilling on an oil rig is a complex and potentially hazardous process. Drilling simulators are used to train workers in the operation of drilling equipment, allowing them to practice various scenarios and develop the requisite skills to prevent accidents.

Equipment Operation

Whether it’s a crane, winch, or forklift, the operation of heavy machinery is a fundamental part of oil rig work. Simulators are indispensable for training equipment operators, enabling them to gain practical experience without the inherent risks associated with on-the-job training.

Navigation and Safety Protocols

Simulated environments can accurately replicate the layout of an oil rig, enabling workers to familiarize themselves with the rig’s layout, safety protocols, and navigation. This familiarity significantly reduces the risk of falls and other accidents caused by a lack of familiarity with the rig’s layout and safety measures.

2. Personal Protective Equipment (PPE)

Personal Protective Equipment (PPE) is a fundamental component of worker safety on oil rigs. Workers are required to wear appropriate PPE, including helmets, safety glasses, gloves, and steel-toed boots, to reduce the risk of injuries. The selection and use of PPE can be reinforced through simulation exercises, allowing workers to understand the importance of proper equipment and its effectiveness in different scenarios.

Regular safety inspections of equipment and machinery are critical for identifying and addressing potential issues before they lead to accidents. Rig operators often have dedicated safety teams responsible for inspecting and maintaining all equipment, ensuring that it is in proper working condition.

4. Emergency Response Plans

Oil rig operators have comprehensive emergency response plans in place to deal with fires, explosions, and other critical incidents. These plans include evacuation procedures, assembly points, and the location of first-aid stations. Drills are regularly conducted to ensure that all workers are familiar with these procedures and can respond swiftly in the event of an emergency.

5. Environmental Safeguards

Protecting the environment is a top priority for the oil and gas industry. Rig operators implement environmental protection measures to prevent and mitigate the impact of spills and leaks. These measures may include the use of containment booms to contain spills, rapid response teams trained in environmental cleanup, and the deployment of equipment designed to minimize the environmental impact of drilling operations.

6. Improved Technology

Advancements in technology have played a significant role in enhancing safety on oil rigs. Improved drilling techniques, automation, and remote monitoring systems have made drilling and extraction processes safer and more efficient. These technologies help reduce the likelihood of accidents and enable rapid response in the event of an emergency.

Conclusion

Oil rig injuries are a serious problem in the oil and gas industry. But the industry is working hard to make things safer. They’re doing this by using strict safety rules, giving workers lots of training, and using new technology to prevent accidents. As the world still needs a lot of oil, it’s crucial to keep oil rig workers safe and protect the environment. We’re learning from past accidents and making safety better so that oil drilling can be safer and more sustainable in the future.