Understanding Oil and Gas Management: Key Aspects and the Pivotal Role of Simulation Technology

The management of oil and gas involves a vast range of activities, from exploration and extraction to transportation and distribution. We will delve into the complexity of oil and gas management in this article, analyzing its essential components, problems, the developing landscape of this vital sector, and how simulation is revolutionizing oil and gas management.

What are Key Aspects of Oil and Gas Management

Exploration and Production

The first phase of oil and gas management is exploration and production (E&P). These procedures entail locating possible hydrocarbon reserves, drilling wells, and extracting crude oil and natural gas. Geologists, engineers, and other professionals are critical in determining viable drilling locations. Advanced technologies, such as seismic surveys and drilling techniques, have revolutionized E&P, enabling more precise identification of hydrocarbon reservoirs.

Challenges in Exploration and Production

Environmental Concerns: Balancing the need for energy resources with environmental conservation is a significant challenge. The industry must minimize the environmental impact of drilling and extraction processes.

Technological Advancements: Keeping up with rapidly evolving drilling and exploration technologies is crucial for the industry’s competitiveness.

Geopolitical Issues: Oil and gas reserves are often located in politically sensitive regions, which can lead to geopolitical challenges and supply disruptions.

Refining and Processing

After crude oil and natural gas are recovered, they must be refined and processed in order to be used in a variety of applications. Refineries are critical in this phase because they convert crude oil into lucrative products like gasoline, diesel, and petrochemicals. To maintain efficiency and product quality, the refining process necessitates innovative equipment and competent workers.

Challenges in Refining and Processing

Environmental Regulations: Cleaner and more efficient refining procedures are required as environmental restrictions become increasingly stringent.

Energy Efficiency: To minimize carbon emissions and operational expenses, refineries must enhance their energy efficiency.

Supply Chain Management: It is vital to manage the supply chain to ensure a steady flow of crude oil and products to meet market demand.

Transportation and Distribution

Transportation and distribution of oil and gas products entails transporting them from refineries to end users. This is typically achieved through pipelines, ships, trucks, and railroads. Effective logistics and infrastructure are essential for ensuring a steady and secure supply of energy resources.

Challenges in Transportation and Distribution

Infrastructure Investment: Maintaining and expanding transportation infrastructure is a constant challenge, requiring significant investment.

Safety and Security: Ensuring the safe transport of hazardous materials is a top priority for the industry.

Market Fluctuations: Oil and gas prices can fluctuate significantly, affecting transportation and distribution decisions.

Environmental and Regulatory Compliance

Compliance with environmental and regulatory requirements is a critical part of oil and gas management. The sector is under increasing scrutiny and pressure to lessen its environmental impact. Compliance with environmental rules and regulations is critical for retaining a social license to operate and avoiding potential legal and reputational risks.

Challenges in Environmental and Regulatory Compliance

Shifting Regulations: Regulatory requirements are constantly evolving, necessitating adaptability and proactive compliance strategies.

Public Perception: Maintaining a positive public image is challenging in an industry often viewed with skepticism due to environmental concerns.

Health and Safety: Ensuring the health and safety of workers and communities is a top priority and a constant challenge in the oil and gas sector.

Technology and Innovation

In the oil and gas industry, technology and innovation are driving forces. Drilling techniques, automation, data analytics, and renewable energy are all transforming the industry. To be competitive and sustainable, oil and gas management must accept and adapt to technological advances.

Challenges in Technology and Innovation:

Talent Acquisition: Attracting and retaining skilled personnel to drive innovation is a continuous challenge.

Energy Transition: As the world shifts towards cleaner energy sources, oil and gas management faces the challenge of diversifying and adapting to meet changing energy demands.

How Simulation Technology is Revolutionizing the Oil and Gas Management

Simulation technology is helping the oil and gas industry simulate and analyze different elements of their operations, from exploration and production to refining and distribution.

Exploration and Reservoir Simulation

Reservoir modeling is a critical application of simulation technology in the oil and gas sector. This technology is used by geologists and engineers to generate computer models of subsurface reservoirs, which provide a detailed understanding of the reservoir’s features. Experts can use simulations to forecast how reservoirs would perform under various situations, allowing them to optimize drilling and production plans.

Benefits of Reservoir Simulation

Improved Reservoir Management: Simulations improve reservoir characterization, resulting in better production techniques and higher recovery rates.

Risk Mitigation: Companies can anticipate possible issues and manage risks by modeling numerous manufacturing scenarios.

Cost Reduction: By giving insights that lead to more effective well location and operation, simulation technology helps minimize drilling and exploration expenses.

Drilling and Well Control Simulation

Drilling and well control also benefit from simulation technology. Drilling and well control simulators provide drilling operators with a realistic training environment in which they may practice various drilling situations and well control procedures in a safe and regulated environment. These simulations aid in the development of drilling personnel’s abilities and preparedness.

Benefits of Drilling Simulation

Enhanced Training: Drilling training simulation system provides a safe and cost-effective way to teach drilling operators and increase their ability to manage drilling operations.

Error Prevention: Simulations enable well control responses to be practiced, lowering the chance of human mistake during actual drilling operations.

Realistic Scenarios: In a controlled setting, operators can face a wide range of drilling obstacles, from equipment faults to unanticipated wellbore conditions.

Refinery and Process Optimization

Refineries and processing plants leverage simulation technology for process optimization. By creating digital replicas of refinery operations, companies can identify inefficiencies, reduce energy consumption, and enhance product quality. These simulations enable engineers to experiment with different process variables and make informed decisions to improve plant operations.

Benefits of Refinery Simulation

Efficiency Gains: Simulations help identify opportunities to streamline operations, reduce energy consumption, and increase overall process efficiency.

Product Quality: By fine-tuning refining processes, companies can produce higher-quality products while reducing waste and emissions.

Cost Savings: Optimizing processes through simulation can lead to significant cost savings in terms of energy, maintenance, and raw materials.

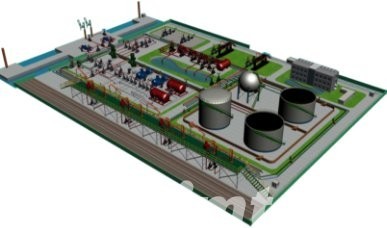

Pipeline and Distribution Management

In pipeline and distribution management, Oil and gas gathering and transportation simulation systems are used. Pipeline simulation software enables businesses to examine variables such as flow rates, pressure, and temperature to ensure the safe and efficient transport of hydrocarbons from refineries to end users.

Benefits of Pipeline Simulation

Safety Assurance: Pipeline simulations help identify potential issues and ensure safe and reliable transportation of hazardous materials.

Resource Optimization: By optimizing pipeline operations, companies can minimize energy consumption and maintenance costs.

Compliance Support: Simulation technology assists in meeting regulatory requirements for pipeline operations and environmental protection.

Conclusion

Oil and gas management is a complicated and multifaceted field that is vital to our daily lives and the global economy. Effective management in this industry necessitates addressing a wide range of issues, from environmental concerns to geopolitical concerns. Oil and gas management must adapt and innovate to ensure a sustainable and reliable energy future as the world continues to evolve. Simulation technology is a critical tool for ensuring the industry’s long-term viability and dependability. Oil and gas simulation enables companies to navigate the complex landscape of this vital sector with confidence and precision.