Understanding LNG Process: How to Enhance Its Efficiency and Safety

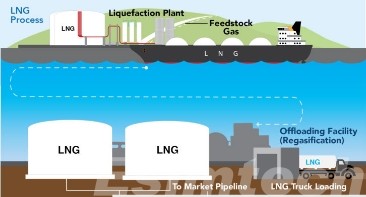

Liquefied Natural Gas has revolutionized the global energy market, providing a cleaner and more efficient means of transporting natural gas over long distances. The LNG process involves several critical stages, each playing a vital role in converting natural gas into its liquefied form and ensuring its safe and efficient transport and usage.

Key Stages of the LNG Process

1. Natural Gas Extraction

The journey of LNG begins with the extraction of natural gas from underground reservoirs. Natural gas is predominantly composed of methane (CH4) and is sourced through drilling wells, either onshore or offshore. Advanced extraction techniques, such as hydraulic fracturing, are often employed to access deeper or more challenging reserves.

2. Pre-Treatment

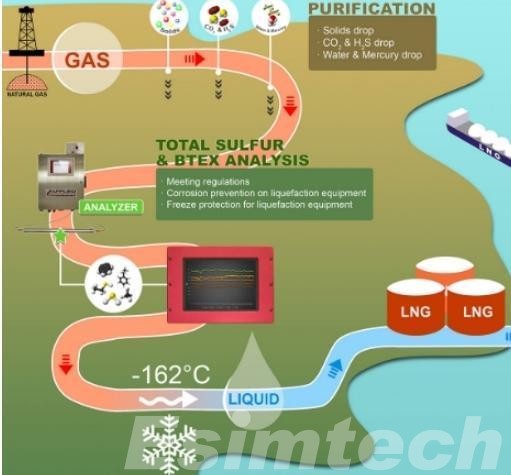

Before natural gas can be liquefied, it must be purified through a series of pre-treatment steps. This process removes impurities that can cause operational issues or affect the quality of the LNG.

Key Pre-Treatment Steps

- Dehydration: Water vapor is removed to prevent the formation of ice or hydrates during cooling.

- Acid Gas Removal: Carbon dioxide (CO2) and hydrogen sulfide (H2S) are eliminated to avoid freezing and corrosion.

- Mercury Removal: Traces of mercury are extracted to protect aluminum equipment from amalgamation and degradation.

- Heavy Hydrocarbon Removal: Heavier hydrocarbons are separated to prevent solidification during liquefaction.

3. Liquefaction

The liquefaction stage is central to the LNG process. Here, natural gas is cooled to approximately -162°C (-260°F), transforming it into a liquid. This phase change reduces the gas volume by about 600 times, making storage and transportation more feasible.

Liquefaction Technologies:

- Cascade Process: Utilizes multiple refrigerants with different boiling points to cool the gas in successive stages.

- Mixed Refrigerant Process: Employs a single refrigerant mixture to achieve the necessary cooling.

- Expander Cycle: Uses turbo-expanders to cool the gas through expansion.

4. Storage

After liquefaction, LNG is stored in specially designed cryogenic tanks. These tanks are highly insulated to maintain the low temperatures required to keep LNG in its liquid state. Storage tanks are typically spherical or cylindrical and are designed to minimize heat ingress.

5. Transportation

Transporting LNG is primarily done via LNG carriers, which are specialized ships equipped with insulated tanks to keep the Liquefied Natural Gas at its required cryogenic temperature. These carriers play a crucial role in the global LNG supply chain, enabling the efficient transport of LNG from production sites to markets around the world.

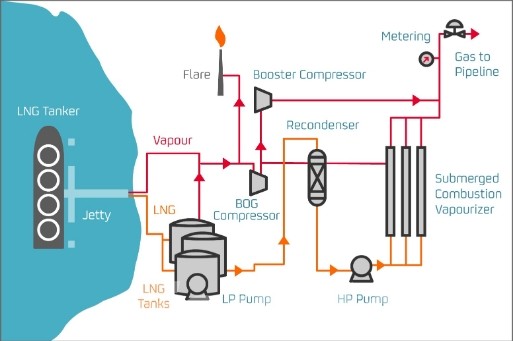

6. Regasification

Once LNG reaches its destination, it undergoes regasification. This process involves heating the Liquefied Natural Gas to convert it back into its gaseous form. The regasified natural gas is then fed into the local distribution networks for use in residential, commercial, and industrial applications.

7. Distribution and Utilization

The final stage of the LNG process is the distribution and utilization of the natural gas. This gas is distributed through pipelines to end-users, where it is used for heating, electricity generation, industrial processes, and as a cleaner fuel alternative for vehicles.

Technological Advancements in the LNG Process

Here’s a chart summarizing key technological advancements in the LNG process, highlighting their benefits and applications across various stages of LNG production, storage, transportation, and utilization.

| Category | Technological Advancements | Key Benefits | Applications |

| Floating LNG (FLNG) | Floating LNG Units | Exploitation of remote offshore gas fields Reduced infrastructure costs Mobility and reduced environmental footprint | Offshore gas extraction and processing Direct liquefaction at sea |

| Small-Scale LNG Plants | Modular LNG Plants | Flexibility and scalability Lower capital expenditure | Remote and niche markets Industrial sites, islands |

| Liquefaction Technologies | Dual Mixed Refrigerant (DMR) Process Nitrogen Expansion Cycle Improved Compressor Design | Increased cooling efficiency Enhanced safety and simplified process Reduced energy usage, increased reliability | Liquefaction plants Cooling cycles Compressors and heat exchangers |

| Storage Solutions | Membrane Tanks Composite Materials Integrated Monitoring Systems | Reduced weight and cost Enhanced durability and thermal performance Improved safety and operational efficiency | Cryogenic storage tanks LNG storage Real-time storage condition monitoring |

| LNG Bunkering and Fueling | Bunkering Vessels Dual-Fuel Engines Automated Bunkering Systems | Efficient LNG transfer to ships Flexibility in fuel usage Increased efficiency and safety | Marine fuel transfer Marine engines LNG fueling process |

| Digitalization & Automation | Advanced Process Control (APC) Predictive Maintenance Digital Twins | Real-time optimization, reduced energy consumption Reduced downtime, lower maintenance costs Real-time monitoring, diagnostics, and optimization | LNG plant operations Equipment maintenance Virtual replicas of physical assets |

| Environmental & Safety | Methane Leak Detection Carbon Capture and Storage (CCS) Enhanced Safety Systems | Early detection and mitigation of methane leaks Reduced CO2 emissions Improved safety and emergency response | Emissions monitoring LNG facilities LNG operations |

How Simulation Technology is Used in the LNG Process

Simulation technology has become an integral part of the Liquefied Natural Gas industry, offering significant benefits across various stages of the LNG process.

1. Process Design and Optimization

Simulation technology is extensively used during the design phase of LNG facilities to create accurate models of the entire LNG process. These models help engineers optimize process parameters, evaluate different design options, and predict the performance of the system under various conditions.

Key Applications

- Thermodynamic Modeling: Simulate the behavior of natural gas and refrigerants during the liquefaction process to optimize cooling cycles and improve energy efficiency.

- Flow Simulation: Analyze fluid dynamics within pipelines, compressors, and heat exchangers to ensure optimal flow rates and minimize pressure drops.

- Heat Transfer Analysis: Model heat exchange processes to design more efficient heat exchangers and insulation systems.

2. Safety and Risk Management

Safety is paramount in the LNG industry, and simulation technology plays a crucial role in enhancing safety and managing risks. Advanced simulation tools allow for the prediction and analysis of potential hazards, enabling proactive measures to mitigate risks.

Safety Applications

Hazard and Operability Studies (HAZOP): Simulate various operational scenarios to identify potential hazards and assess their impact on the system.

- Explosion and Fire Modeling: Predict the behavior of gas leaks, explosions, and fires to design effective safety measures and emergency response plans.

- Structural Integrity Analysis: Simulate the impact of extreme conditions (e.g., earthquakes, storms) on LNG storage tanks and infrastructure to ensure structural integrity.

3. Training and Skill Development

Simulation technology provides a safe and controlled environment for training personnel in LNG operations. Virtual simulators replicate real-world conditions, allowing operators to gain hands-on experience without the risks associated with live operations.

Training Benefits

- Operator Emergency Training Simulators: Provide realistic training scenarios for operators to practice routine tasks, emergency response, and troubleshooting.

- Virtual Reality (VR) Training: Use immersive VR environments to train personnel on equipment handling, maintenance procedures, and safety protocols.

- Scenario-Based Training: Simulate specific scenarios, such as equipment failures or process upsets, to enhance problem-solving skills and decision-making capabilities.

4. Real-Time Monitoring and Control

Advanced simulation tools are integrated with real-time monitoring and control systems to enhance the operational efficiency of LNG facilities. These tools enable continuous monitoring of process parameters and provide predictive insights for better decision-making.

Operational Applications

- Advanced Process Control: Use real-time data and predictive models to optimize process control, improve yield, and reduce energy consumption.

- Digital Twins: Create virtual replicas of physical assets that mirror real-time operations, allowing for continuous monitoring, diagnostics, and optimization.

- Predictive Maintenance: Utilize simulation models and machine learning algorithms to predict equipment failures and schedule maintenance activities proactively.

5. Environmental Impact Assessment

Simulation technology aids in assessing and mitigating the environmental impact of LNG operations. By modeling emissions, pollutant dispersion, and other environmental factors, companies can develop strategies to minimize their ecological footprint.

Environmental Applications

- Emission Modeling: Simulate the emission of greenhouse gases and other pollutants to assess their impact and develop mitigation strategies.

- Dispersion Modeling: Predict the spread of pollutants in the air or water to design effective containment and remediation measures.

- Life Cycle Analysis (LCA): Evaluate the environmental impact of the entire LNG process, from extraction to end-use, to identify opportunities for improvement.

6. Supply Chain and Logistics Optimization

Simulation tools are used to optimize the supply chain and logistics of LNG, ensuring efficient transportation and distribution from production sites to end-users.

Logistics Applications

- Supply Chain Simulation: Model the entire LNG supply chain to optimize logistics, reduce costs, and improve delivery reliability.

- Fleet Management: Simulate the operation of LNG carriers to optimize routes, scheduling, and fleet utilization.

- Inventory Management: Use simulations to forecast demand and optimize storage and inventory levels across the supply chain.

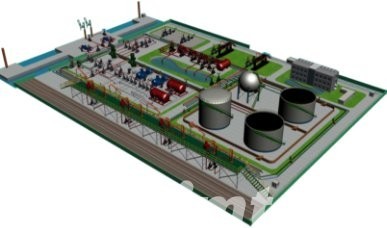

Why Choose Esimtech Oil and Gas Simulators for LNG Process

Esimtech oil and gas simulators offer a comprehensive and realistic training solution for LNG processes. By combining advanced technology with industry expertise, these simulators provide a safe and cost-effective environment to learn and master complex operations. With features like detailed process modeling, interactive simulations, and real-world scenarios, Esimtech empowers operators to enhance their skills, optimize performance, and mitigate risks in LNG production.

Key benefits include:

- Enhanced operator proficiency: Hands-on experience in a safe, controlled environment.

- Optimized process efficiency: Identify bottlenecks and improve overall plant performance.

- Reduced operational risks: Prevent costly errors and accidents through realistic simulations.

- Accelerated training: Efficient knowledge transfer and skill development.

- Cost-effective: Significant savings compared to on-site training or real-world errors.