Underbalanced vs. Overbalanced Drilling: A Comprehensive Comparison

In the oil and gas industry, underbalanced and overbalanced drilling are two commonly used techniques for drilling wells, each with distinct advantages and applications. The decision between these methods affects well integrity, production potential, and operational safety. This comparison highlights the distinctions, benefits and considerations associated with underbalanced and overbalanced drilling.

Understanding Underbalanced and Overbalanced Drilling

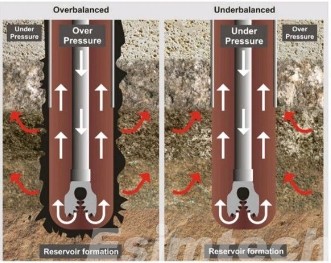

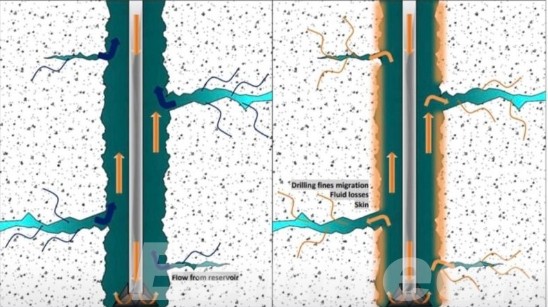

- Underbalanced Drilling (UBD): Underbalanced drilling is a technique in which the pressure of the drilling fluid in the wellbore is intentionally kept lower than the formation pressure. This approach is designed to allow formation fluids (oil, gas, or water) to flow into the wellbore during drilling. It often requires specialized equipment and careful control to maintain pressure below the formation level.

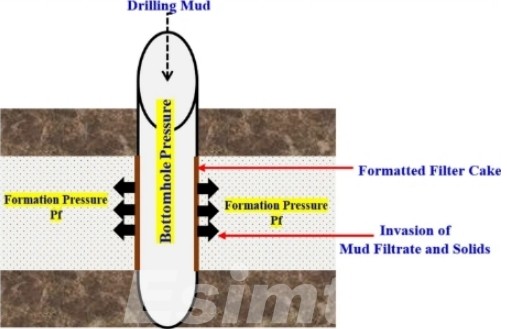

2. Overbalanced Drilling (OBD): In contrast, overbalanced drilling keeps the wellbore pressure higher than the formation pressure. This is achieved by using drilling mud with a weight high enough to prevent formation fluids from entering the wellbore. Overbalanced drilling is the most commonly used method and is typically preferred when formation stability and well control are prioritized.

Advantages and Disadvantages of Underbalanced Drilling

Advantages

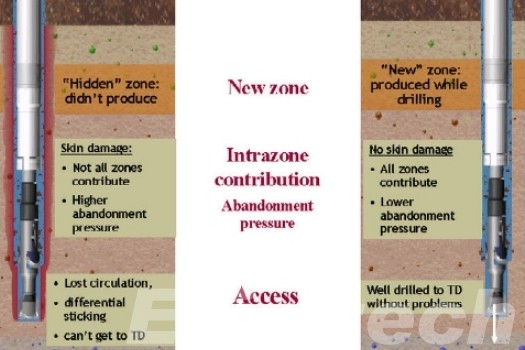

- Reduced Formation Damage: UBD drilling minimizes damage to the reservoir as fluids from the formation flow into the wellbore, preventing mud from penetrating and potentially clogging the formation.

- Enhanced Production Rates: Since underbalanced conditions allow for continuous fluid entry, the well can produce hydrocarbons during drilling, providing a more accurate assessment of production potential and potentially enhancing early production.

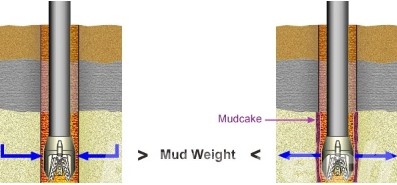

- Reduced Differential Sticking: Lower wellbore pressure reduces the risk of differential sticking, which can occur when the drill string becomes lodged in the wellbore due to pressure differentials.

- Drilling in Depleted Reservoirs: UBD drilling is often chosen for reservoirs with low pressures or depleted zones, where traditional overbalanced methods would require significant mud weight increases, raising costs and operational complexity.

Disadvantages

- Safety Risks: Underbalanced drilling is associated with higher risks, such as blowouts and gas kicks, as formation fluids are intentionally allowed to enter the wellbore. Specialized well-control equipment and trained personnel are essential to handle these risks.

- Increased Equipment and Operational Costs: The need for additional pressure management and containment equipment, such as rotating control devices (RCDs) and multiphase separators, can increase the initial setup costs.

- Environmental Concerns: Unintended releases of formation fluids, including gases, can pose environmental risks. Careful handling and disposal methods are essential to prevent contamination.

Advantages and Disadvantages of Overbalanced Drilling

Advantages

- Enhanced Safety and Control: Overbalanced drilling provides a more predictable and controlled environment by preventing formation fluids from entering the wellbore, reducing the risk of blowouts and gas kicks.

- Simplified Operations: Overbalanced drilling typically requires standard equipment, making it more cost-effective and straightforward. Less specialized equipment is needed, which simplifies logistics and reduces costs.

- Suitable for Most Formations: OBD drilling is versatile and applicable to various formation types, especially where stability and well control are priorities.

Disadvantages

- Potential for Formation Damage: Higher wellbore pressure can force drilling fluids into the formation, causing blockages and reducing the reservoir’s permeability, which can impede productivity.

- Risk of Differential Sticking: The pressure differential in OBD drilling can lead to sticking, which can halt drilling operations and require expensive interventions.

- Limited Productivity Assessment: Since formation fluids are prevented from entering the wellbore, OBD drilling does not offer real-time insights into the reservoir’s productive capacity during drilling.

Key Differences Between Underbalanced and Overbalanced Drilling

| Aspect | Underbalanced Drilling (UBD) | Overbalanced Drilling (OBD) |

| Pressure Relationship | Wellbore pressure is kept lower than formation pressure, allowing reservoir fluids to enter the wellbore. | Wellbore pressure is maintained higher than formation pressure, preventing fluid influx from the formation. |

| Fluid Flow | Allows formation fluids to flow into the wellbore, enabling real-time assessment of reservoir productivity. | Prevents formation fluids from entering the wellbore, which aids in stability and well control. |

| Primary Goal | Minimize formation damage and improve production rates by avoiding overpressure in the formation. | Maintain control of the wellbore and ensure operational safety by preventing uncontrolled influx of formation fluids. |

| Equipment Complexity | Requires specialized equipment such as rotating control devices, multiphase separators, and well control equipment to handle influxes safely. | Uses standard equipment for drilling, making it more straightforward and cost-effective to implement in many applications. |

| Safety and Risks | Higher risk of blowouts, kicks, and complications due to the formation of fluids entering the wellbore. Advanced well control systems are necessary. | Lower risk due to controlled wellbore pressure. Better suited for stable, predictable drilling conditions. |

| Formation Impact | Minimizes damage to the formation by reducing fluid invasion into the rock matrix, preserving permeability and porosity. | Higher mud pressure can damage the formation by clogging pores, which may reduce future production rates. |

| Use of Simulations | Simulations are critical for modeling potential fluid influxes, pressure management, and equipment needs in real-time scenarios, enabling safer and more efficient operations. | Drilling simulations are used primarily to ensure mud weight and well control settings are sufficient to maintain a stable wellbore. |

Key Considerations in Selecting the Right Approach Between Underbalanced and Overbalanced Drilling

| Consideration | Underbalanced Drilling (UBD) | Overbalanced Drilling (OBD) |

| Reservoir Conditions | Suitable for depleted, low-pressure, or sensitive formations where minimizing formation damage is critical. | Best for stable, high-pressure formations where maintaining control is a priority. |

| Formation Damage | Reduces formation damage by allowing natural fluid flow into the wellbore, preserving permeability and enhancing production. | Higher risk of damage due to drilling fluid invasion, which may reduce formation permeability and future productivity. |

| Well Control and Safety | Higher risk due to influx of formation fluids; requires advanced well control systems and operator expertise to manage potential blowouts and kicks. | Greater safety and control as formation fluids are prevented from entering the wellbore, reducing the likelihood of kicks and blowouts. |

| Production Goals | Ideal for maximizing initial production and enabling real-time reservoir evaluation, as fluid inflow offers insights into formation characteristics. | Effective for long-term stability where well control is essential, and immediate production assessment is less critical. |

| Cost Factors | Higher initial costs due to specialized equipment but may lower long-term costs by preserving formation productivity and reducing remedial work. | Lower initial costs with standard equipment but may incur higher long-term expenses if formation damage limits productivity. |

| Environmental Impact | Requires stringent environmental controls due to potential for fluid release, especially gases, into the environment during drilling. | Lower environmental risk as wellbore pressure prevents fluid influx, minimizing potential for uncontrolled fluid release. |

| Operational Complexity | High complexity, needing skilled personnel, specialized drilling equipment, and continuous monitoring to handle real-time fluid influx and maintain safety. | Lower complexity and more predictable operation, with standard procedures and equipment making it easier to implement. |

| Regulatory Requirements | Tighter regulatory scrutiny due to the inherent risks associated with managing uncontrolled formation fluids, requiring permits and compliance measures. | Standard regulatory oversight generally applies, with fewer complex permit requirements compared to UBD. |

Overall, both underbalanced and overbalanced drilling methods have unique benefits and are chosen based on specific project requirements, reservoir conditions, and production objectives. Underbalanced drilling, with its advantages in formation preservation and productivity enhancement, is gaining attention, particularly in complex or low-pressure reservoirs. However, the increased risks and costs may make overbalanced drilling a more feasible option for conventional, stable reservoirs.