Training and Skill Development for Sidetrack Drilling

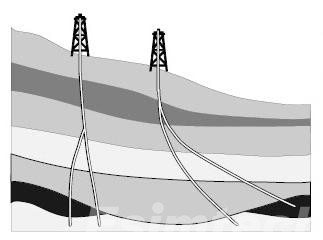

Sidetracking drilling is a key technology in the oil and gas industry that allows operators to re-enter and deviate from existing wellbores to reach undeveloped reservoirs, bypass obstacles, or optimize production. This process requires professional skills and rigorous training to ensure safety, efficiency, and cost-effectiveness. This article delves into the importance of sidetracking, the key skills required, and the training methods used to develop these skills.

Importance of Sidetrack Drilling

Sidetrack drilling holds a pivotal role in the oil and gas industry for several compelling reasons:

- Enhanced Resource Recovery: It allows operators to access additional hydrocarbons in mature fields, thereby extending the productive life of existing wells and maximizing resource extraction from established assets.

- Cost Efficiency: By utilizing existing wellbores and infrastructure, sidetrack drilling significantly reduces the expenses associated with drilling new wells, making it a more economical option for oil and gas extraction.

- Operational Adaptability: This technique provides a practical solution for navigating around obstructions or damaged sections within a wellbore, ensuring continuous and efficient production operations.

- Environmental Conservation: Sidetrack drilling minimizes the need for new wells, thus reducing the environmental impact associated with drilling activities and supporting sustainable resource management.

Through these advantages, sidetrack drilling not only enhances the economic viability of oil and gas operations but also promotes environmental stewardship and operational resilience.

Key Skills Required for Sidetrack Drilling

Sidetrack drilling demands a specialized skill set that goes beyond conventional drilling practices. To successfully execute a sidetrack operation, personnel must possess a comprehensive understanding of various technical and operational aspects.

Technical Skills

- Wellbore Trajectory Planning: This involves a deep understanding of geological formations, wellbore conditions, and drilling objectives. Engineers must be proficient in using advanced software to design optimal sidetrack trajectories, considering factors such as doglegs, build rates, and azimuth changes.

- Drilling Engineering: A strong foundation in drilling fluid chemistry, rheology, and hydraulics is essential for maintaining wellbore stability and optimizing drilling efficiency. Engineers must be able to select appropriate drilling fluids, manage fluid properties, and prevent complications such as stuck pipe or lost circulation.

- Directional Drilling: In-depth knowledge of directional drilling techniques, including motor and steerable assemblies, is crucial for achieving accurate wellbore placement. Personnel must be adept at real-time adjustments to maintain the desired trajectory and compensate for unexpected deviations.

- MWD/LWD Technology: Proficiency in utilizing measurement while drilling (MWD) and logging while drilling (LWD) tools is vital for monitoring wellbore conditions, gathering real-time data, and making informed decisions. This includes understanding the capabilities and limitations of different MWD/LWD sensors and interpreting the acquired data.

- Formation Evaluation: The ability to interpret well logs and other geological data to assess formation properties and identify potential drilling hazards is essential for effective sidetrack planning and execution.

Operational Skills

- Risk Assessment and Management: A systematic approach to identifying, evaluating, and mitigating risks associated with sidetrack drilling is crucial. This includes developing contingency plans and emergency procedures to address potential challenges.

- Problem-Solving: The capacity to analyze complex drilling problems, develop creative solutions, and make timely decisions under pressure is essential for overcoming obstacles and ensuring operational success.

- Teamwork and Communication: Effective collaboration with cross-functional teams, including geologists, engineers, and drilling crews, is vital for successful sidetrack operations. Clear and concise communication is essential for coordinating activities, sharing information, and resolving issues.

- Safety Management: Adherence to safety protocols and procedures is paramount in the drilling industry. Personnel involved in sidetrack drilling must have a strong safety mindset and be committed to preventing accidents and injuries.

By cultivating a workforce with a strong foundation in these key skills, companies can enhance their ability to execute sidetrack projects safely, efficiently, and profitably.

Training Methods for Sidetrack Drilling

Effective training for sidetrack drilling is multifaceted and requires a blend of theoretical knowledge and practical application. To develop well-rounded professionals, a comprehensive training program should incorporate the following methods:

Classroom Instruction

Theoretical underpinnings are essential for understanding the complexities of sidetrack drilling. Classroom training provides a structured environment to learn about:

- Wellbore Trajectory Planning: In-depth knowledge of geological formations, wellbore conditions, and drilling objectives to design optimal sidetrack trajectories.

- Drilling Engineering: Comprehensive understanding of drilling fluid selection, hydraulics, well control, and mud engineering principles.

- Directional Drilling: Theoretical basis of steering techniques, measurement while drilling (MWD), and logging while drilling (LWD) tools.

- Formation Evaluation: Interpretation of well logs and other geological data to assess reservoir potential and optimize well placement.

- Risk Management: Identifying potential hazards, evaluating risks, and developing mitigation strategies.

On-the-Job Training

Practical experience is indispensable for developing the skills required for sidetrack drilling. On-the-job training under the mentorship of experienced professionals allows trainees to:

- Gain Hands-on Experience: Participate in various stages of sidetrack drilling operations, including planning, execution, and evaluation.

- Develop Problem-Solving Skills: Learn to address challenges and make decisions in real-time scenarios.

- Build Teamwork and Communication Skills: Collaborate with different teams and effectively communicate during operations.

Simulation Training

Simulation-based training offers a safe and controlled environment to practice complex drilling scenarios. Advanced drilling simulators can replicate real-world conditions, allowing trainees to:

- Master Equipment Operation: Gain proficiency in operating drilling equipment and systems.

- Develop Decision-Making Skills: Practice responding to various drilling challenges and emergencies.

- Enhance Wellbore Trajectory Control: Improve skills in steering the wellbore accurately and efficiently.

- Reduce On-the-Job Risks: Minimize the potential for accidents and equipment damage by providing a controlled training environment.

Continuous Learning

The oil and gas industry is constantly evolving, necessitating ongoing professional development. To stay updated with the latest technologies and best practices, companies should encourage employees to participate in:

- Conferences and Workshops: Attend industry events to learn about new developments and network with peers.

- Online Courses and Webinars: Access a wide range of training resources through online platforms.

- Mentorship Programs: Foster knowledge sharing and skill development through mentorship relationships.

By combining classroom instruction, on-the-job training, simulation, and continuous learning, companies can develop highly skilled sidetrack drilling personnel capable of executing complex projects safely and efficiently.

Conclusion

Sidetrack drilling is a complex and demanding operation that necessitates highly skilled personnel. Investing in comprehensive training and skill development programs is crucial for ensuring operational success, safety, and cost-efficiency. By providing drilling teams with the essential knowledge and expertise, companies can improve their execution of sidetrack projects and maximize returns.