Top Drive Drilling in Unconventional Environments

The relentless pursuit of energy resources has driven the drilling industry to constantly innovate and adapt. Traditional drilling methods, while effective in conventional settings, often fall short in the face of harsh and unconventional environments. Top drive drilling (TDD) technology has emerged as a transformative solution, offering superior efficiency, safety, and precision in these challenging landscapes.

History of Top Drive Drilling

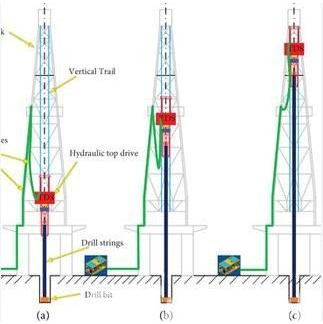

Top drive drilling emerged in the mid-20th century as an alternative to the traditional rotary table method, which rotated the drill string from the bottom. Early prototypes appeared in the 1960s, aiming to enhance drilling speed, safety, and efficiency by rotating and circulating the drill pipe from the top. By the 1980s, significant advancements led to the widespread adoption of more refined and reliable top drive systems.

Hydraulic top drives were among the first significant innovations, providing the power needed for longer and more complex drill strings, especially beneficial in deepwater and offshore drilling. Later, electric top drives introduced greater precision and efficiency, seamlessly integrating with modern automated systems.

Top drive systems transformed drilling operations by allowing continuous drilling without frequent stops to connect new sections of drill pipe, thus reducing downtime and increasing efficiency. They also improved safety by minimizing manual handling of drill pipe, reducing accident risks.

Modern top drives are equipped with advanced control systems for precise drilling management and real-time monitoring. This continuous evolution has made top drive systems essential in both onshore and offshore environments, particularly in complex and challenging drilling scenarios. Today, they remain a cornerstone of efficient, safe, and cost-effective drilling operations.

Importance of Top Drive Drilling in Unconventional Environments

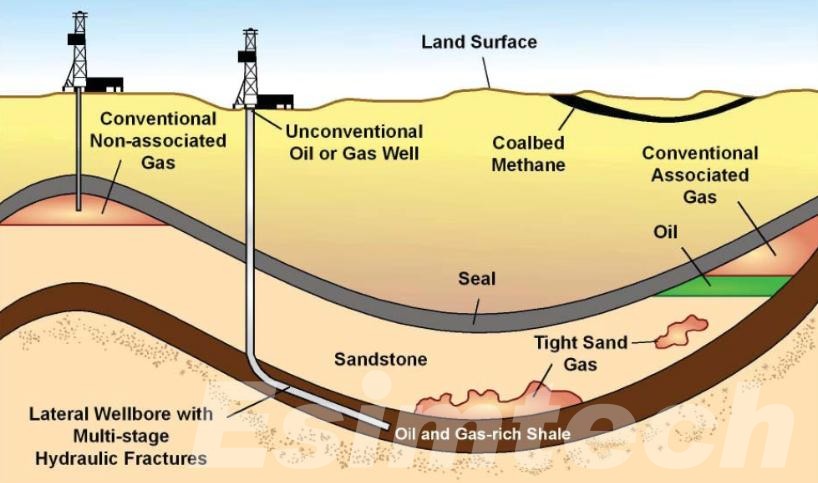

Unconventional drilling environments, encompassing deepwater offshore fields to extreme arctic regions, present a multitude of intricate challenges. Traditional rotary drilling methods, while effective in conventional settings, often struggle to meet the demands of these harsh landscapes. Top drive drilling (TDD) technology has emerged as a transformative solution, offering a comprehensive set of advantages that render it an indispensable tool for unconventional drilling operations.

- Precision Drilling in Complex Geology: Unconventional environments are frequently characterized by highly complex geological formations. TDD’s superior control over drill pipe rotation translates to unmatched accuracy in wellbore trajectory adjustments. This enables operators to navigate intricate formations with exceptional precision, ensuring they reach previously inaccessible resources and optimize wellbore placement for maximum production.

- Enhanced Drilling Efficiency: Time is a critical factor in any drilling operation, but it becomes especially paramount in unconventional environments where logistical complexities and harsh conditions can significantly escalate costs. TDD eliminates the need for time-consuming trips to add or remove drill pipe sections (tripping) that are common in conventional drilling. By enabling continuous drill pipe rotation, TDD significantly accelerates drilling times, leading to substantial cost savings and improved operational efficiency – a game-changer in remote or challenging environments.

- Prioritizing Worker Safety: Drilling operations inherently carry a degree of risk. Conventional drilling methods often involve manual handling of heavy drill pipe sections, posing a significant threat of worker injuries. TDD minimizes the need for manual handling by rotating the drill pipe from the surface. This drastically improves safety for drilling crews, a paramount concern in unconventional environments where medical evacuation can be complex and time-consuming.

- Environmental Responsibility: The environmental impact of drilling operations is a growing concern, particularly in sensitive ecosystems or fragile polar regions. The faster drilling times enabled by TDD contribute to a smaller environmental footprint. Less rig time translates to lower emissions and a reduced overall footprint on the environment. This responsible approach is crucial for ensuring the sustainability of drilling operations in unconventional environments.

In essence, TDD acts as a multifaceted solution for unconventional drilling. It conquers geological complexities with precision, accelerates operations for improved efficiency, prioritizes worker safety, and minimizes environmental impact. These combined benefits solidify TDD’s position as an indispensable tool for pushing the boundaries of energy exploration in unconventional environments, facilitating the secure and responsible extraction of resources in challenging landscapes.

Technological Advancements in Top Drive Drilling

Top drive drilling (TDD) technology, with continuous advancements propelling its capabilities forward at an impressive rate. Here’s a deeper exploration of some key developments that are transforming the industry:

- Integration of Automation and Advanced Control Systems: Modern TDD systems seamlessly integrate with sophisticated automation and control systems that transcend mere data monitoring. These systems leverage advanced algorithms to conduct real-time analyses of critical drilling parameters such as torque, weight on bit, and downhole pressure. This analytical prowess translates into:

- Automated Response Systems: The control systems can autonomously adjust drilling parameters based on pre-defined thresholds and wellbore conditions. This proactive approach optimizes drilling efficiency while mitigating risks associated with human error.

- Real-Time Optimization: Drilling engineers can leverage the continuous stream of data from these systems to continuously refine drilling strategies throughout the operation. This ensures that drilling parameters remain within optimal ranges, leading to expedited drilling times and reduced wear and tear on drill pipe and equipment.

- Advanced Material Integration for Enhanced Performance: The development of high-strength, lightweight materials has significantly impacted TDD design, fostering advancements in two key areas:

- Increased Power and Torque Capacity: The utilization of materials like high-strength alloys enables the construction of top drives with superior power and torque output. This translates to the ability to penetrate tougher formations and effectively utilize larger diameter drill pipe, both of which are crucial for deep and challenging wells.

- Compact and Efficient Designs: Lighter materials pave the way for the development of more compact top drives. This proves particularly advantageous for space-constrained environments on drilling rigs, such as offshore platforms where every square foot of space is a valuable commodity.

- Sensor Integration and Real-Time Data Acquisition: The strategic integration of downhole sensors within the drill string provides a treasure trove of valuable data on wellbore conditions, including:

- Formation Characteristics: Sensors can detect subtle changes in rock density, porosity, and fluid content. This allows for a more comprehensive understanding of the geological formations being traversed, enabling proactive adjustments to drilling parameters.

- Vibration Monitoring: Downhole vibration can inflict significant damage on drill pipe and compromise wellbore integrity. Sensors can detect and transmit real-time vibration data, allowing drilling crews to adjust drilling parameters and mitigate vibration risks before they escalate into costly problems.

These advancements, coupled with ongoing research and development efforts, are constantly pushing the boundaries of TDD capabilities. At the same time, top drive drilling simulation technology is also under continuous development and innovation, providing new ideas for sustainable oil and gas drilling operations.

As a result, we can expect even more groundbreaking applications of this technology to emerge in the years to come, further revolutionizing the way we approach drilling operations in unconventional environments.

Applications in Unconventional Environments

Top drive drilling (TDD) has become an indispensable tool for unlocking resources in challenging and unconventional environments. Here’s a deeper dive into how TDD tackles these situations:

The vast potential of deepwater oil and gas reserves is countered by the immense pressure and complex geology found at these depths. Traditional drilling methods struggle to maintain wellbore stability and achieve the precise directional control needed to reach target formations. TDD’s superior control over drill pipe rotation allows for the use of advanced drilling techniques like managed pressure drilling (MPD) This enables real-time pressure adjustments in the wellbore, mitigating the risk of blowouts and ensuring wellbore integrity in these extreme environments. Furthermore, the ability to make rapid adjustments to drilling parameters with TDD is crucial for navigating the often-unpredictable formations encountered in deepwater fields.

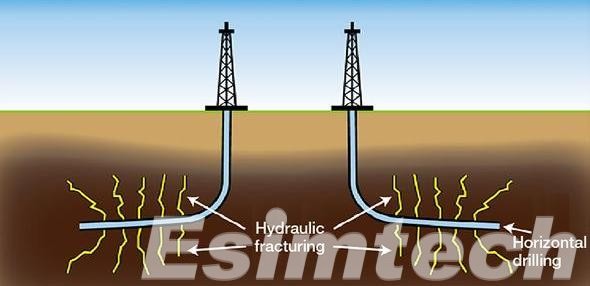

- Shale Oil and Gas Extraction:

The unconventional nature of shale oil and gas resources lies in their low permeability, meaning they are trapped in tightly packed rock formations. Traditional drilling methods are often ineffective in reaching these resources. TDD’s ability to facilitate directional drilling is instrumental here. By precisely controlling the trajectory of the drill pipe, operators can create long, horizontal wellbores within the shale formation, maximizing the well’s contact area with the trapped hydrocarbons. This significantly increases production rates and unlocks the vast potential of shale reserves. Additionally, the real-time data acquisition capabilities of modern TDD systems allow for continuous monitoring of formation characteristics, enabling the use of specialized drilling tools and techniques optimized for shale formations.

- Arctic Exploration:

The harsh climate and logistical challenges of the Arctic pose significant obstacles to conventional drilling operations. TDD’s compact design and ability to function reliably in sub-zero temperatures make it a game-changer. The reduced rig footprint associated with TDD minimizes environmental impact in these sensitive ecosystems. Additionally, the automation capabilities of modern TDD systems can help reduce the need for on-site personnel, ensuring worker safety in these remote and hazardous environments.

- Beyond Oil and Gas:

The versatility of TDD extends beyond fossil fuel exploration. Its ability to precisely navigate complex geological formations and drill deep boreholes makes it valuable for geothermal energy exploration, where accessing hot underground reservoirs is crucial. Furthermore, TDD’s potential applications are being explored in scientific drilling projects, enabling researchers to collect valuable data from previously inaccessible depths within the Earth’s crust.

In conclusion, TDD’s adaptability and efficiency make it a key technology for unlocking resources in unconventional environments. As we continue to push the boundaries of energy exploration, TDD will undoubtedly play a critical role in securing a sustainable and resource-rich future.

Conclusion

Top drive drilling has changed the way we approach drilling in unconventional environments. By prioritizing efficiency, safety, and environmental responsibility, TDD has established itself as a vital tool for the future of oil and gas exploration. As technology continues to evolve, we can expect even more innovative applications of TDD, pushing the boundaries of what’s achievable in the ever-demanding world of energy exploration.