Thermal Enhanced Oil Recovery in Extracting Heavy Oil from Challenging Reservoirs

Thermal Enhanced Oil Recovery (TEOR) is an advanced method employed to extract heavy crude oil from reservoirs that are challenging to exploit using conventional techniques. It has become a critical technology in maximizing the recovery of hydrocarbons from mature and challenging oil reservoirs. This article delves into the principles, methods, benefits, challenges and future solutions of Thermal Enhanced Oil Recovery as well as how simulation technology used for the optimization of its operations.

Understanding Thermal Enhanced Oil Recovery

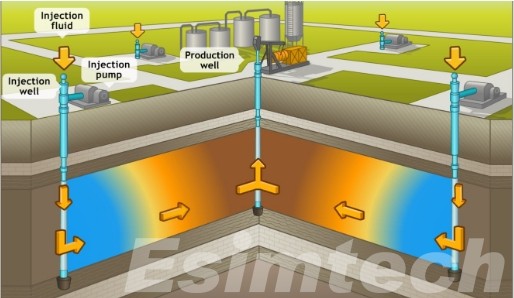

Thermal Enhanced Oil Recovery involves the application of heat to reduce the viscosity of heavy crude oil, making it easier to extract. This enhanced oil recovery method is particularly effective in reservoirs where the oil is too thick or the reservoir too complex for traditional extraction techniques. By heating the oil, TEOR improves its flow characteristics, allowing it to move more freely through the reservoir to the production wells.

Methods of Thermal Enhanced Oil Recovery

1. Steam Injection

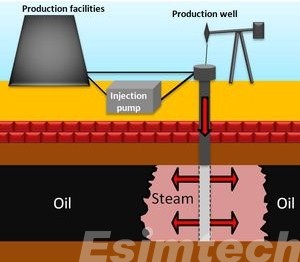

- Steam Flooding: Continuous injection of steam into the reservoir raises the temperature, decreasing oil viscosity and driving the oil toward production wells. This method enhances oil mobility and recovery rates.

- Cyclic Steam Stimulation (CSS): Also known as “huff and puff,” this method involves injecting steam into a well, allowing it to soak, and then producing the heated oil. The cycle can be repeated multiple times to maximize recovery.

2. In-Situ Combustion

This technique involves injecting air or oxygen into the reservoir to ignite a portion of the oil. The combustion generates heat, which further reduces the viscosity of surrounding oil and pushes it toward production wells. This method can significantly enhance oil recovery while utilizing a portion of the reservoir’s hydrocarbons.

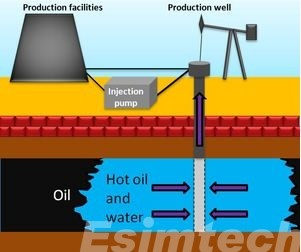

3. Hot Water Flooding

In this method, hot water is injected into the reservoir. While not as effective as steam, hot water can still reduce oil viscosity and help displace oil toward production wells. It is often used in situations where steam injection is not feasible or cost-effective.

4. Electromagnetic Heating

Electromagnetic waves are employed to heat the reservoir rock and the oil. Although still in experimental phases, this method has potential for reservoirs where traditional steam injection is impractical.

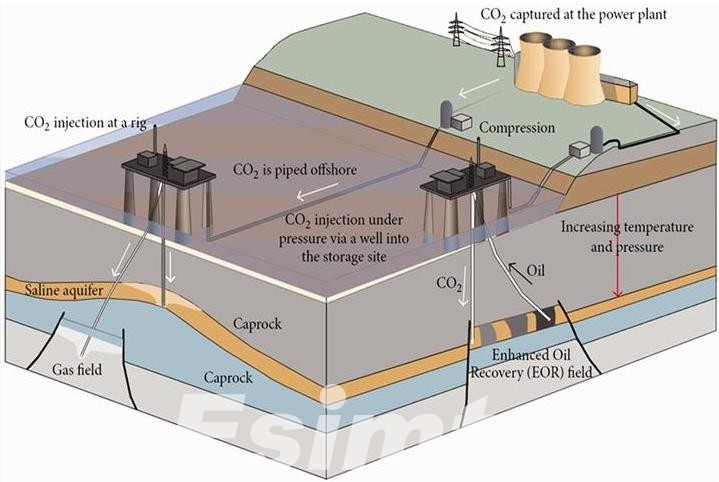

5. Thermal Assisted Gas Injection (TAGI)

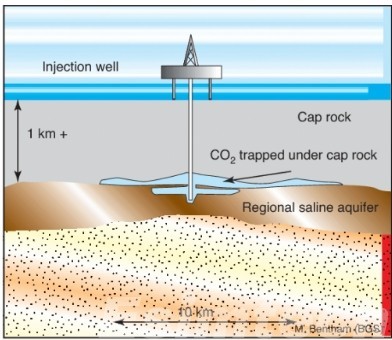

This method combines gas injection with thermal processes. By injecting gases (like CO2 or natural gas) along with heat, it improves oil recovery while also reducing greenhouse gas emissions. The gas helps to maintain reservoir pressure and improve oil flow.

Benefits of Thermal Enhanced Oil Recovery

This chart highlights the key benefits of Thermal EOR, emphasizing its importance in modern oil recovery strategies.

| Benefit | Description |

| Increased Recovery Rates | Significantly enhances oil recovery from mature and heavy oil fields. |

| Improved Efficiency | Reduces oil viscosity, leading to higher production rates and economic returns. |

| Utilization of Existing Infrastructure | Often leverages existing wells and infrastructure, reducing development costs. |

| Environmental Benefits | Minimizes the need for new drilling, reducing the overall environmental footprint. |

| Extended Productive Life | Prolongs the life of oil fields, maximizing resource utilization over time. |

| Cost-Effectiveness | Can be more cost-effective than drilling new wells, especially in mature fields. |

| Enhanced Oil Mobility | Improves flow characteristics of oil, facilitating easier extraction. |

| Potential for CO2 Management | Some methods allow for carbon capture and storage, reducing greenhouse gas emissions. |

| Adaptability | Can be tailored to specific reservoir conditions and oil characteristics. |

Challenges and Future Solutions in Thermal Enhanced Oil Recovery

Challenges

| Challenge | Description |

| High Energy Consumption | TEOR methods, particularly steam injection, require significant energy inputs, leading to high operational costs. |

| Water Usage | Techniques like steam flooding consume large volumes of water, raising concerns in water-scarce regions. |

| Reservoir Management | Effective heat distribution and oil mobilization require advanced monitoring and control systems. |

| Environmental Impact | Potential issues such as subsidence, groundwater contamination, and greenhouse gas emissions need careful management. |

| Economic Viability | Fluctuating oil prices can affect the economic feasibility of TEOR projects. |

| Operational Complexity | Thermal Enhanced Oil Recovery operations can be technically complex, requiring specialized knowledge and equipment. |

| Regulatory Compliance | Meeting environmental regulations and standards can be challenging and resource-intensive. |

Future Solutions

| Solution | Description |

| Energy Efficiency Improvements | Developing more energy-efficient technologies and methods to reduce operational costs. |

| Water Management Strategies | Implementing water recycling and alternative sourcing methods to minimize freshwater usage. |

| Advanced Monitoring Technologies | Utilizing IoT and AI for real-time monitoring and optimization of Thermal Enhanced Oil Recovery processes. |

| Sustainable Practices | Adopting practices that minimize environmental impacts, such as carbon capture and storage (CCS). |

| Economic Models | Creating robust economic models to assess the viability of Thermal EOR under fluctuating market conditions. |

| Training and Development | Providing ongoing education and training for personnel to enhance operational efficiency and safety. |

| Regulatory Engagement | Actively engaging with regulatory bodies to ensure compliance and streamline approval processes. |

How Simulation Technology is Used in Thermal Enhanced Oil Recovery

Simulation technology plays a crucial role in Thermal Enhanced Oil Recovery by providing detailed models and predictions for the behavior of reservoirs under thermal recovery processes.

- Reservoir Modeling: Simulations create detailed geological and fluid models of the reservoir, accounting for rock properties, fluid behavior, and temperature variations. This helps in understanding how heat will propagate through the formation.

- Thermal Process Optimization: Various thermal methods, like steam injection or in-situ combustion, can be simulated to determine the most effective approach for a specific reservoir. This includes optimizing steam quality, injection rates, and timing.

- Predicting Production Performance: Simulations help forecast oil production rates and the expected recovery factor over time, allowing operators to make informed decisions about project viability and resource allocation.

- Identifying Challenges: By simulating different scenarios, operators can identify potential challenges such as heat loss, reservoir heterogeneity, and fluid mobility issues, enabling them to develop strategies to mitigate these risks.

- Enhanced Decision-Making: Simulation results provide valuable insights that guide field development strategies, including well placement, completion techniques, and operational adjustments.

- Economic Analysis: By simulating various operational scenarios, companies can conduct cost-benefit analyses and evaluate the economic feasibility of implementing thermal EOR in a specific field.

- Real-Time Monitoring and Adjustment: Advanced oil and gas simulation tools can integrate real-time data, allowing for dynamic updates to models and operational strategies based on current performance and reservoir conditions.

- Training and Education: Simulation technologies serve as educational tools for training personnel in EOR techniques, helping them understand complex processes and improve operational decision-making.

Conclusion

Thermal Enhanced Oil Recovery is an essential technology for extracting heavy oil from challenging reservoirs. Through applying heat to reduce oil viscosity, Thermal EOR maximizes recovery rates, improves efficiency, and extends the productive life of oil fields. Despite its challenges, ongoing advancements promise to make TEOR an even more effective and sustainable solution for meeting global energy needs.