The Vital Role of Thermal Reservoir Simulation in Optimizing EOR Techniques

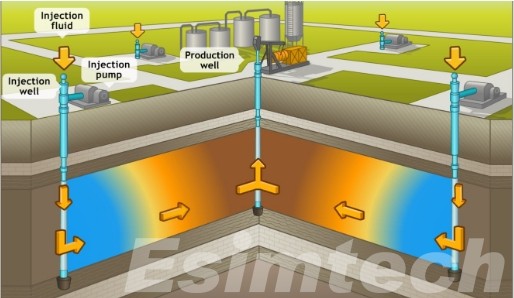

Thermal reservoir simulation is a specialized field within petroleum engineering, focusing on the modeling of oil reservoirs subjected to thermal methods like steam injection, hot water flooding, and in-situ combustion, crucial for optimizing enhanced oil recovery techniques. By predicting how heat will interact with the reservoir’s fluids and rock, thermal reservoir simulation allows engineers to design more effective recovery strategies. This article explores the significance of thermal reservoir simulation, the methods used, and the challenges and innovations in this reservoir simulation.

Understanding Thermal Reservoir Simulation

What is Thermal Reservoir Simulation

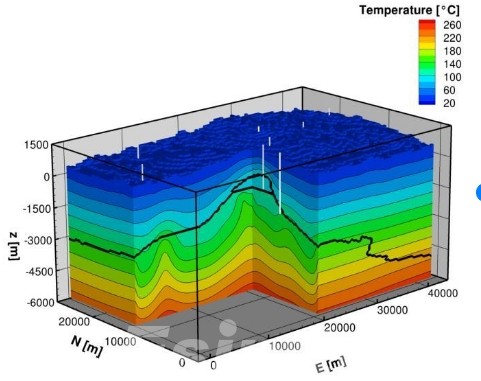

Thermal reservoir simulation involves creating a detailed mathematical model of an oil reservoir that accounts for the effects of temperature on fluid properties, rock-fluid interactions, and flow dynamics. The primary objective is to simulate how the introduction of heat impacts oil viscosity, reservoir pressure, and ultimately, oil recovery rates.

Role in Enhanced Oil Recovery

In mature fields where conventional oil extraction methods are no longer effective, thermal enhanced oil recovery techniques are often employed. By reducing the viscosity of heavy oils, these methods facilitate easier flow towards production wells. Thermal reservoir simulation helps in designing these processes, optimizing heat distribution, and predicting the economic viability of the recovery methods.

Key Components of Thermal Reservoir Simulation

| Key Component | Description | Impact |

| Heat Transfer and Distribution | Models how heat moves through reservoir rock and fluids, including conduction, convection, and radiation. | Ensures proper heat distribution, reducing oil viscosity for improved flow and recovery. |

| Fluid Flow and Phase Behavior | Accounts for changes in fluid properties like viscosity and phase transitions (e.g., steam to water) under varying temperatures and pressures. | Predicts fluid movement, optimizing the efficiency of recovery processes. |

| Reservoir Geology and Structure | Incorporates spatial distribution of rock properties, including porosity, permeability, and geological features like faults or fractures. | Enhances the accuracy of predictions regarding heat and fluid movement. |

| Chemical Reactions and Combustion | Simulates chemical reactions and phase changes, such as in-situ combustion, which affect fluid flow and recovery processes. | Ensures controlled and efficient processes, maximizing oil recovery. |

Challenges in Thermal Reservoir Simulation

Challenges in thermal reservoir simulation are multifaceted, reflecting the complexity of accurately modeling the behavior of reservoirs under thermal conditions.

- Complexity of Multi-Phase Flow

Simulating multi-phase flow in a thermal reservoir is inherently complex, as it involves the interaction of different phases (oil, water, gas) under varying temperature and pressure conditions. Accurate modeling of these interactions is challenging but essential for reliable predictions.

2. Computational Demands

Thermal reservoir simulations are computationally intensive, requiring significant processing power and time, especially for large or highly detailed models. Advances in computing technology and algorithms are continually improving the efficiency and accuracy of these simulations, but the demand for more detailed and accurate models continues to grow.

3. Uncertainty in Reservoir Properties

Accurate simulation depends on the quality of the input data, including reservoir properties such as porosity, permeability, and fluid composition. However, these properties can vary widely within a reservoir and are often uncertain or poorly characterized, leading to potential inaccuracies in simulation results.

4. Integration with Field Data

A key challenge is integrating simulation results with real-time field data. Continuous monitoring of the reservoir and updating the simulation model based on actual production data is essential for refining predictions and optimizing EOR processes. This requires advanced data management and analysis tools.

5. Modeling of Chemical Reactions and Phase Changes

In certain thermal EOR methods, such as in-situ combustion, chemical reactions and phase changes play a significant role. Accurately modeling these reactions, including the generation of gases and changes in fluid composition, is challenging but essential for a realistic simulation. Failure to accurately model these reactions can lead to incorrect predictions of reservoir behavior, potentially resulting in ineffective oil recovery methods and increased operational risks.

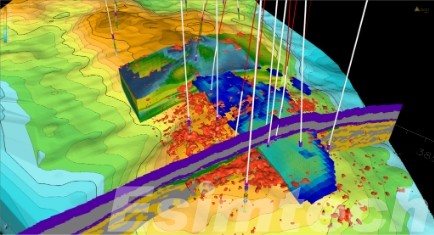

6. Variability in Geological Features

The presence of geological features like faults, fractures, and varying rock properties can significantly impact the effectiveness of thermal EOR methods. Accurately representing these features in the simulation is challenging due to their complexity and variability. Inaccurate representation of geological features can lead to misjudgments about how heat and fluids will move through the reservoir, reducing the effectiveness of the oil recovery process.

Innovations in Thermal Reservoir Simulation

Innovations in thermal reservoir simulation are driving significant improvements in the accuracy, efficiency, and effectiveness of enhanced oil recovery (EOR) methods. These advancements are helping engineers to better predict reservoir behavior, optimize recovery processes, and manage resources more effectively.

1. Machine Learning and Artificial Intelligence (AI) Integration

- Description: Machine learning and AI are increasingly being integrated into thermal reservoir simulation. These technologies analyze large datasets, recognize patterns, and make predictive models more accurate. AI can also automate parts of the simulation process, reducing the time required for model setup and calibration.

- Impact: The integration of AI enhances predictive capabilities, leading to more efficient and optimized recovery processes. It allows for faster adjustments to the simulation model as new data becomes available, improving the overall decision-making process.

2. High-Performance Computing (HPC)

- Description: The use of high-performance computing enables the simulation of more complex and detailed models, allowing engineers to consider larger reservoirs and more intricate geological features with greater precision. HPC supports real-time simulation updates, providing the ability to respond quickly to changes in reservoir conditions.

- Impact: HPC allows for faster, more accurate simulations, reducing the time required to analyze scenarios and make decisions. This results in more efficient resource management and better economic outcomes for EOR projects.

3. Improved Geological and Fluid Models

- Description: Advances in seismic imaging, core sampling, and fluid analysis have led to more accurate geological and fluid models. These improvements provide better input data for simulations, enhancing the ability to model the complex interactions between rock properties, fluid flow, and heat transfer.

- Impact: More accurate geological and fluid models result in more reliable simulations, improving the effectiveness of thermal EOR methods. These models help to identify the best strategies for heat distribution and fluid movement within the reservoir.

4. Hybrid Simulation Techniques

- Description: Combining thermal reservoir simulation with other EOR modeling techniques, such as chemical flooding or gas injection, is an emerging trend. Hybrid simulation approaches provide a more comprehensive understanding of the reservoir’s behavior by modeling the complex interactions between different recovery techniques.

- Impact: Hybrid simulations offer a more holistic view of the reservoir, leading to more effective recovery strategies. By considering multiple EOR methods in tandem, engineers can optimize the overall recovery process, potentially increasing the amount of recoverable oil.

5. Advanced Data Integration and Management

- Description: Innovations in data management are improving the ability to integrate real-time field data into thermal reservoir simulations. This includes advancements in data acquisition, storage, and processing technologies, which allow for more seamless and efficient updating of simulation models as new information becomes available.

- Impact: Enhanced data integration leads to more accurate and real-time oil and gas simulations, allowing for better optimization of the recovery process. It enables continuous monitoring and adjustment of the simulation model, improving the responsiveness to changing reservoir conditions.

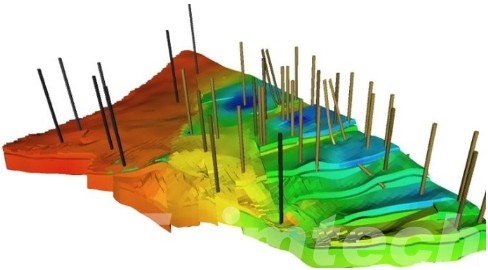

6. Enhanced Visualization and Simulation Tools

- Description: New visualization tools and simulation platforms are providing engineers with more intuitive and detailed views of reservoir behavior. These tools offer better 3D modeling capabilities, allowing for more precise analysis of how heat and fluids move through the reservoir.

- Impact: Improved visualization aids in the interpretation of complex simulation results, making it easier to identify potential issues and optimize recovery strategies. It enhances collaboration among teams by providing clearer and more accessible representations of the simulation data.

7. Reduced Order Modeling (ROM) Techniques

- Description: Reduced Order Modeling (ROM) techniques simplify complex simulations by focusing on the most critical aspects of the reservoir model. ROM allows for faster simulations without sacrificing significant accuracy, making it possible to run more scenarios in less time.

- Impact: ROM techniques increase the efficiency of the simulation process, enabling quicker decision-making and more rapid iteration of different recovery strategies. This can be particularly valuable in time-sensitive projects or when computational resources are limited.

8. Development of Smart Reservoir Management Systems

- Description: Smart reservoir management systems integrate simulation models with real-time monitoring and control technologies. These systems use advanced sensors and data analytics to continuously update the simulation model and adjust operational parameters in real-time.

- Impact: Smart reservoir management systems enhance the ability to optimize recovery processes dynamically, leading to more efficient operations and better resource management. They provide a higher level of control and precision, reducing waste and improving economic returns.

In summary, thermal reservoir simulation is an indispensable tool of modern oil recovery, enabling engineers to design, optimize, and manage EOR processes with greater precision. Despite the challenges, ongoing innovations in computing, modeling, and data integration are continuously improving the accuracy and efficiency of these reservoir simulations.