The Role of Multistage Fracturing in Enhancing Unconventional Resource Extraction

The extraction of unconventional resources, such as shale gas and tight oil, has transformed the global energy landscape. This evolution has largely been driven by advancements in drilling techniques, particularly multistage fracturing. This article explores traditional drilling methods and their limitations, the principles behind hydraulic fracturing, the concept of multistage fracturing, its benefits, and the technological advances that have propelled this technique to the forefront of resource extraction.

Traditional Drilling Methods and Their Limitations

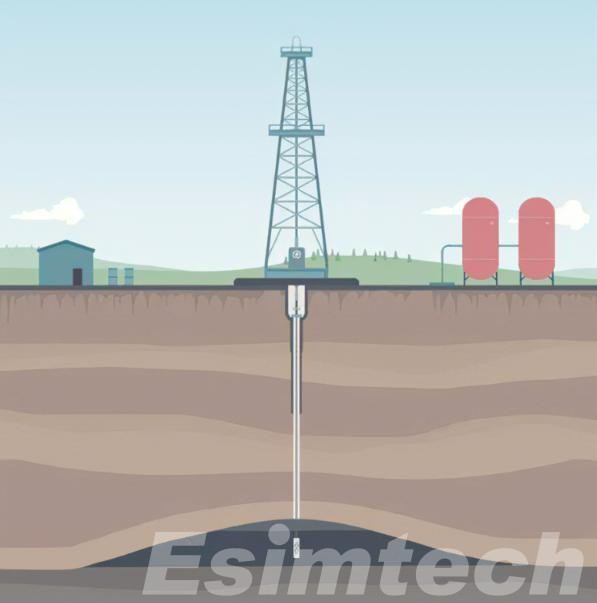

Conventional drilling methods, primarily vertical drilling, were once the standard for oil and gas extraction. These methods are effective in reservoirs with high permeability, where hydrocarbons flow easily through porous rock formations toward the wellbore. However, they fall short when applied to unconventional resources like shale gas or tight oil, which are trapped in low-permeability rocks. Vertical wells are often unable to access large sections of these formations, limiting the amount of recoverable oil or gas.

Another limitation of traditional drilling is that it typically involves a single wellbore targeting a relatively small area of the reservoir. This approach leaves significant portions of the resource untapped, reducing overall recovery efficiency. Additionally, drilling multiple vertical wells to increase production raises costs and environmental impacts. These limitations have driven the need for advanced techniques, such as horizontal drilling and multistage fracturing, to effectively unlock unconventional resources.

Multistage Fracturing Used in Oil and Gas

Multistage fracturing has become a pivotal technique in the extraction of unconventional oil and gas resources, allowing operators to increase the productivity of wells and access previously untapped reserves. By creating multiple fractures along the length of a wellbore, typically in horizontal wells, this method optimizes the recovery of hydrocarbons trapped in low-permeability rock formations such as shale and tight sandstone.

Principles of Hydraulic Fracturing

Hydraulic fracturing forms the backbone of modern oil and gas extraction, particularly in unconventional reservoirs. This technique involves injecting high-pressure fluids into rock formations to create fractures, making it easier for oil and gas to flow into the wellbore.

Key elements of hydraulic fracturing include:

- High-Pressure Fluids: A mixture of water, sand (proppant), and chemical additives is pumped into the well at high pressure to fracture the surrounding rock.

- Proppant: Sand or similar materials keep the fractures open, ensuring continued oil and gas flow after pressure is released.

- Fracture Propagation: High-pressure fluids penetrate natural cracks and weaknesses in the rock, boosting permeability and improving hydrocarbon flow.

While highly effective in boosting well production, traditional hydraulic fracturing was generally limited to creating a single fracture or a few large fractures in vertical wells, restricting the overall contact area with the reservoir.

What Is Multistage Fracturing?

Multistage fracturing builds upon traditional hydraulic fracturing by enabling multiple fractures to be created at different stages along the wellbore, particularly in long horizontal wells. This allows operators to target several zones in the reservoir, increasing the contact area with the oil- or gas-bearing rock and enhancing resource recovery.

Key features of multistage fracturing:

- Sequential Fracturing: The wellbore is divided into different stages, and fractures are created one stage at a time, ensuring maximum coverage of the reservoir.

- Packers and Sliding Sleeves: These specialized tools are used to isolate different sections of the wellbore, allowing operators to precisely control where each fracture is created.

- Multiple Zones: Multistage fracturing can access multiple layers or formations, increasing the productivity of a single well.

In horizontal wells, which are commonly used for unconventional resource extraction, multistage fracturing is particularly valuable because it allows operators to create fractures along the entire length of the well, which can extend for thousands of feet.

Benefits of Multistage Fracturing in Unconventional Resource Extraction

Multistage fracturing has revolutionized the extraction of unconventional resources, such as shale oil and shale gas. This technique offers several significant benefits that have contributed to the growth of the energy industry.

- Increased Production Rates

One of the most significant advantages of multistage fracturing is its ability to significantly increase production rates. By creating multiple fractures along the length of a wellbore, this technique enhances the contact area between the well and the reservoir formation. This allows for greater hydrocarbon flow, resulting in higher production volumes.

- Improved Well Productivity

Multistage fracturing not only increases production rates but also enhances the overall productivity of a well. By optimizing the placement and orientation of fractures, operators can ensure that hydrocarbons flow efficiently to the wellbore. This improved well productivity can result in higher economic returns and lower production costs.

- Enhanced Reservoir Access

Multistage fracturing enables operators to access unconventional reservoirs that were previously considered uneconomical. These reservoirs, characterized by low permeability rock formations, were difficult to exploit using traditional drilling methods. By creating artificial fractures, multistage fracturing allows for the extraction of hydrocarbons from these challenging formations.

- Reduced Environmental Impact

While hydraulic fracturing has raised concerns about potential environmental impacts, such as water contamination and induced seismicity, advancements in technology and regulations have helped to mitigate these risks. Multistage fracturing, when conducted responsibly, can be a relatively low-impact method of extracting energy compared to other fossil fuel extraction techniques.

In general, multistage fracturing has proven to be a game-changer in the extraction of unconventional resources. By increasing production rates, improving well productivity, and providing access to previously untapped reserves, this technique has made a significant contribution to the global energy landscape.

Technological Advances in Multistage Fracturing

Technological innovations have significantly enhanced the efficiency and effectiveness of multistage fracturing in unconventional resource extraction. Here are some key advancements:

1. Fracturing Simulators and Advanced Modeling

Fracturing simulators are cutting-edge software tools that allow engineers to design and optimize fracturing operations before they begin. These simulators can model complex geological formations and predict how fractures will propagate through rock layers, helping operators fine-tune key variables such as fluid pressure, proppant placement, and fracture spacing.

By integrating real-time data from microseismic monitoring and well logs, fracturing simulators provide highly accurate, customized fracture models. This minimizes trial and error during operations and ensures that fractures are created in the most productive zones of the reservoir, significantly improving resource recovery and operational efficiency.

2. Microseismic Monitoring

Microseismic monitoring works hand-in-hand with fracturing simulators by providing real-time feedback on fracture growth. Operators can use this data to validate simulation predictions and make necessary adjustments on the fly, optimizing each stage of fracturing and reducing the risk of unwanted fractures.

3. Enhanced Proppants and Fluids

The development of stronger, more conductive proppants—such as ceramic beads—and advanced fracturing fluids improves fracture effectiveness. These materials, when paired with simulations, can be strategically deployed to maximize the flow of hydrocarbons through the fractures.

4. Automation and Remote Operations

Automation systems help control critical aspects of fracturing, such as pressure management and fluid injection, improving precision. When combined with the insights from fracturing simulators, operators can manage the fracturing process remotely, reducing operational risks and enhancing overall efficiency.

5. Cluster and Zonal Isolation Technologies

Cluster perforation and zonal isolation technologies allow multiple fractures to be initiated in different zones. With the support of fracturing simulators, these techniques can be executed with greater accuracy, ensuring that fractures target the most resource-rich sections of the reservoir.

6. Environmentally Conscious Technologies

Fracturing simulators also contribute to environmental sustainability by optimizing water use and reducing chemical additives in fracturing fluids. Simulation tools help predict how fluids behave in the reservoir, reducing the risk of groundwater contamination and minimizing the environmental footprint of operations.

Multistage fracturing has transformed unconventional resource extraction by overcoming the limitations of traditional drilling. With advances like fracturing simulators, microseismic monitoring, and improved proppants, the process has become more efficient, boosting production and sustainability. As technology evolves, multistage fracturing will remain vital for unlocking new energy potential.