The Role of Mud Logging in Modern Oil and Gas Drilling Operations

In contemporary oil and gas drilling operations, technology is essential for maximizing efficiency, safety, and productivity. Among the various tools and systems employed, mud logging stands out as a critical component of the drilling process. Mud logging monitors well conditions during drilling, offering vital data that supports decision-making and ensures peak performance throughout the operation. This article delves into the key functions and advantages of mud logging, as well as the recent advancements in the field.

What is Mud Logging?

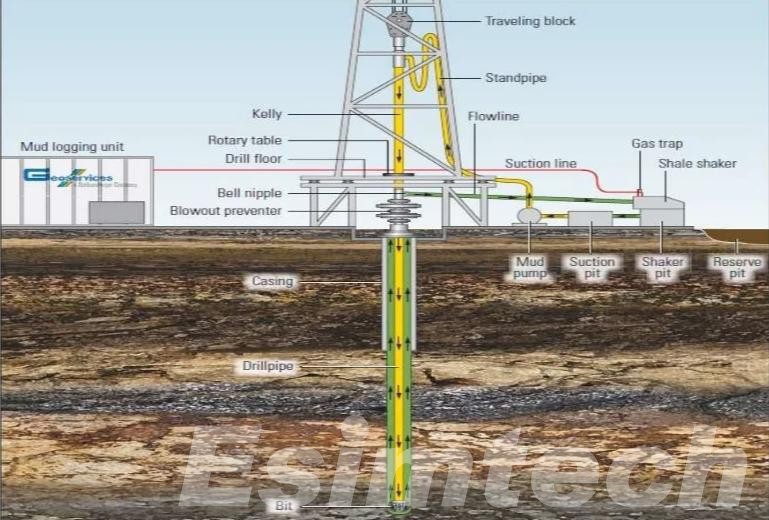

Mud logging refers to the process of collecting, analyzing, and interpreting data from the drilling mud during the drilling of an oil or gas well. The drilling mud, a mixture of water, clay, and chemicals, is circulated through the wellbore to cool the drill bit, lubricate the drilling tools, and remove rock cuttings from the well. As the mud flows back to the surface, mud loggers use specialized equipment to gather vital information about the subsurface formations and well conditions.

Mud logging involves real-time data collection, such as pressure, temperature, gas levels, and the identification of hydrocarbons, which is crucial for understanding the well’s characteristics and behavior.

Purpose of Mud Logging in Drilling

The primary purpose of mud logging is to provide real-time monitoring of the wellbore environment during drilling operations. By analyzing the properties of the drilling mud and the rock cuttings it carries, mud logging helps operators assess the geological formations being drilled and detect the presence of hydrocarbons. This information is critical for making informed decisions about how to proceed with drilling, adjusting drilling parameters, and identifying potential issues before they escalate.

Mud logging also plays a vital role in ensuring safety by detecting early signs of problems like gas kicks, pressure anomalies, or blowouts, which could pose significant risks to both the well and personnel. Additionally, it helps optimize drilling operations by offering insights into the well’s performance, enabling more efficient resource extraction and reducing the risk of non-productive time.

Key Activities Involved in Mud Logging

Mud logging involves a variety of activities aimed at providing real-time data and insights into the well conditions during the drilling process. These activities help in formation evaluation, gas detection, and ensuring the safety of the operation. The key activities involved in mud logging include:

- Cuttings Analysis: Rock cuttings brought to the surface by the circulating drilling mud are collected and examined to identify the type of formation being drilled. This helps in recognizing potential hydrocarbon zones and assessing the geological characteristics of the well.

- Gas Monitoring: Mud loggers monitor the levels of gases, such as methane and hydrogen sulfide, in the returning drilling fluid. This activity is crucial for detecting early signs of gas influx (gas kicks), which can lead to blowouts if not addressed promptly.

- Real-time Data Logging and Reporting: Continuous monitoring of critical parameters like drilling depth, mud weight, temperature, and gas readings allows mud loggers to track the well’s progress and provide detailed reports to the drilling team. These reports inform real-time decision-making.

- Formation Evaluation: By analyzing the collected data, including gas content and cuttings, mud loggers assess the presence and characteristics of different formations. This helps in predicting the behavior of the well and guides decisions regarding casing, wellbore stability, and drilling adjustments.

- Hydrocarbon Detection: The presence of hydrocarbons is identified through gas analysis and cuttings evaluation. This activity helps determine if the well is encountering oil or gas zones, aiding in decisions about further drilling or well completion strategies.

These activities, when performed accurately and efficiently, provide essential information that ensures safe, productive, and cost-effective drilling operations.

Functions of Mud Logging in Drilling Operations

Mud logging serves several critical functions that are essential to the success and safety of drilling operations. These functions include:

- Continuous Monitoring of Well Conditions: Mud logging provides real-time monitoring of the well’s status through the analysis of the drilling mud and cuttings. This constant flow of data allows operators to track the well’s performance and adjust drilling parameters promptly to optimize efficiency and avoid issues.

- Early Detection of Hazards: One of the key roles of mud logging is to identify potential risks early. Mud loggers monitor gas levels, pressure fluctuations, and other indicators in the drilling fluid to detect anomalies such as gas kicks or wellbore instability. By identifying these hazards early, they can prevent more severe issues like blowouts, improving safety for the crew and preventing damage to equipment.

- Formation Identification and Characterization: As the drilling progresses, mud loggers analyze the rock cuttings carried by the mud to identify the various formations encountered. This information helps determine the type of rock being drilled through and can reveal valuable details about the formation’s hydrocarbon potential, helping the team make decisions about casing and other well completion strategies.

- Comprehensive Data Integration: Mud logging doesn’t just gather isolated data points; it integrates with other systems, such as real-time monitoring tools and reservoir models. This creates a more complete picture of the well’s conditions, helping the drilling team understand the wellbore’s behavior and make informed decisions about the next steps in the drilling process.

- Hydrocarbon Detection: A crucial function of mud logging is detecting the presence of hydrocarbons in the well. By analyzing gas content and cuttings, mud loggers can determine if the formation being drilled is likely to contain oil or gas. This information is vital for evaluating the economic potential of the well and determining the next steps for exploration or production.

These functions combine to provide a more efficient, safer, and data-driven drilling process, ultimately contributing to better well outcomes.

Key Benefits of Mud Logging in Drilling Operations

- Enhanced Safety: Mud logging provides critical early warnings of potential hazards, such as gas kicks, pressure changes, or blowout risks. By monitoring gas levels and other parameters in real time, mud loggers help identify dangerous situations before they escalate, significantly improving the safety of drilling operations.

- Cost Savings: By delivering real-time data and insights, mud logging enables operators to make informed decisions that optimize drilling parameters and minimize delays. Early detection of problems allows for timely interventions, reducing the risk of costly non-productive time and equipment damage.

- Improved Well Planning and Decision-Making: The data gathered through mud logging supports more effective well planning by providing a clearer understanding of subsurface formations. This helps engineers make better decisions on well design, casing programs, and drilling techniques, resulting in more efficient operations.

- Accurate Formation Evaluation: Mud logging allows for precise identification and analysis of the geological formations encountered during drilling. This helps in detecting the presence of hydrocarbons and assessing the potential for oil or gas production, which is crucial for exploration and production decisions.

- Environmental Protection: Through careful monitoring of the drilling mud, mud loggers can ensure that proper environmental protocols are followed. By detecting contaminants early and adjusting the composition of the mud, mud logging helps mitigate the environmental impact of drilling activities, ensuring that waste is managed responsibly.

In sum, mud logging enhances the safety, efficiency, and environmental stewardship of drilling operations while providing valuable insights for better decision-making and cost management.

Advances in Mud Logging

The advancements in mud logging technology have significantly enhanced the efficiency, safety, and accuracy of drilling operations. Below are the key benefits:

| Advancement | Description |

| Real-time Data Transmission | Use of satellite and wireless systems to transmit data from the wellsite to onshore, enabling faster decision-making and coordination. |

| Automated Logging Systems | Automation of data collection and analysis for quicker, more accurate detection of anomalies like gas kicks or pressure changes. |

| Advanced Analytical Tools | Enhanced software and data analytics for better prediction and interpretation of well conditions and potential. |

| Integrated Systems | Integration of mud logging systems with other technologies, such as real-time monitoring and seismic data, for a more comprehensive view of well status. |

| Gas Detection Technology | Improved sensors and gas detection systems for more precise measurement of gas influxes, enhancing safety and hydrocarbon detection. |

These innovations have significantly elevated the role of mud logging in modern oil and gas drilling operations.

Mud logging is essential to modern drilling operations, offering real-time data that ensures safety, efficiency, and cost-effectiveness. With advancements in technology, such as automation and real-time data transmission, it continues to play a crucial role in optimizing drilling and identifying potential hazards.