The Role of Mud Circulation System in Sustainable Drilling Practices

Drilling operations are a cornerstone of the oil and gas industry, yet they pose distinct challenges in safety, efficiency, and environmental sustainability. A carefully designed mud circulation system plays a pivotal role in overcoming these challenges, promoting drilling processes that are both effective and eco-friendly.

Mud Circulation System in Oil and Gas

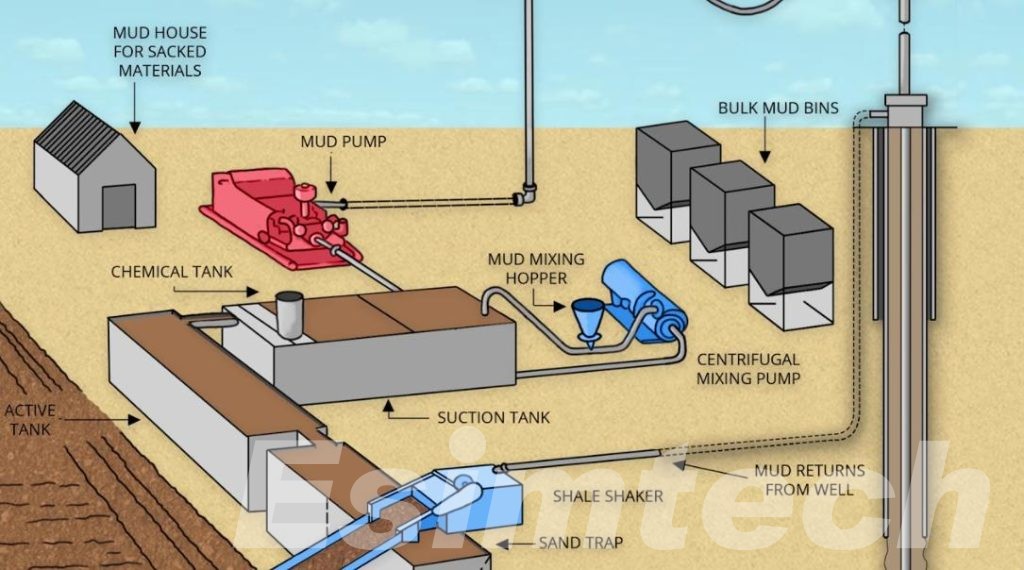

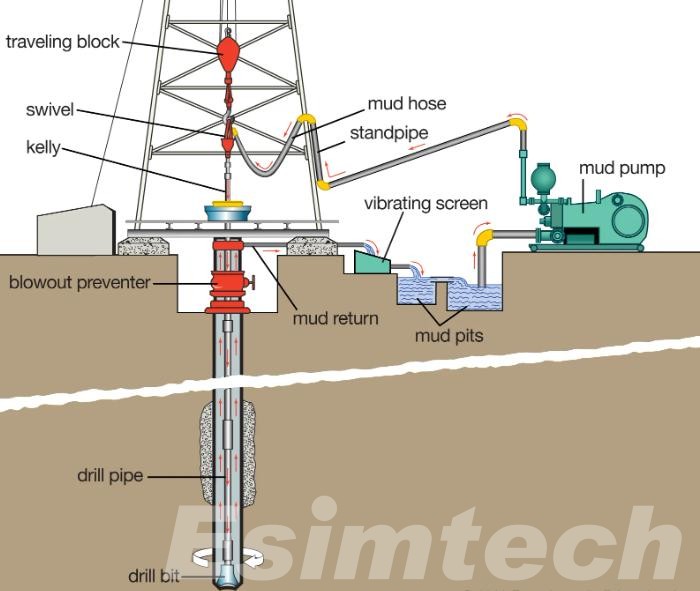

The mud circulation system is at the heart of oil and gas drilling operations, responsible for managing and recycling drilling fluids, commonly referred to as drilling mud. These fluids are used to lubricate the drill bit, cool the drill tools, carry cuttings to the surface, and maintain hydrostatic pressure within the wellbore.

This system is highly complex, involving multiple interconnected components that work together to ensure smooth operations. The efficiency of the mud circulation system directly affects the success of the drilling operation, as well as impacting cost, safety, and environmental performance.

Key Components of Mud Circulation System

First, let’s take a look at the components of the mud circulation system to help understand its role in drilling. These components typically include:

- Mud Pumps: Mud pumps are the heart of the circulation system, responsible for pumping drilling fluid down the drill pipe and circulating it back up through the annulus. Operating under high pressure, they are vital to maintaining a continuous and stable fluid flow.

- Mud Tanks: Mud tanks store and mix drilling fluids, acting as reservoirs where various additives are combined with the base fluid to achieve the required properties. Proper maintenance of these tanks is crucial to ensure consistent fluid quality throughout the drilling process.

- Shale Shakers: These devices remove large drill cuttings from the fluid, acting as the first stage in the solid control process. Effective shale shakers prevent excessive wear on downstream equipment.

- Desanders and Desilters: These components are designed to remove fine solids from the drilling fluid. If not properly managed, these solids can clog the system and impair fluid performance.

- Mud Cleaners: Mud cleaners are integrated units that combine desanders, desilters, and shale shakers. They enhance fluid quality by removing solids of different sizes, ensuring optimal fluid performance.

- Centrifuges: High-speed centrifuges separate remaining fine solids and liquid phases, optimizing the reuse of drilling fluid and minimizing waste.

- Degassers: Degassers remove trapped gases from the drilling fluid to prevent dangerous pressure buildups and maintain well safety.

Types of Drilling Mud

The choice of drilling mud is crucial for optimizing performance, minimizing environmental impact, and ensuring wellbore stability. Different types of drilling fluids are used depending on factors such as the formation being drilled, well depth, pressure conditions, and environmental regulations. Below are the main types of drilling fluids:

- Water-Based Mud (WBM): The most common and environmentally friendly option, WBM consists of water and various additives. It is effective in most formations, although it may not perform as well in highly reactive clays.

- Oil-Based Mud (OBM): OBM offers excellent lubrication and thermal stability, making it well-suited for challenging conditions like high-temperature wells. However, it presents environmental concerns due to its toxicity and the difficulty of disposal.

- Synthetic-Based Mud (SBM): SBM strikes a balance between the performance of OBM and the environmental advantages of Water-Based Mud (WBM). It utilizes synthetic oils that are less toxic and more biodegradable, making it a preferred option for offshore drilling.

- Air or Foam Drilling Fluids: These fluids use air or a mixture of air and water to reduce fluid volume, making them suitable for drilling through unstable formations or when minimal fluid interaction is desired.

Benefits of Mud Circulation System in Sustainable Drilling

Mud circulation system is key to achieving sustainability in drilling operations. It meets the growing demand for environmentally friendly and efficient practices in the oil and gas industry. Here are a few of the most important benefits of mud circulation system in sustainable drilling, detailed below:

Enhancing Resource Efficiency

Efficient resource management is a key advantage of the mud circulation system. In drilling operations, large amounts of water, energy, and chemicals are typically consumed. However, a well-maintained mud circulation system helps conserve these resources, making the process more resource-efficient.

- Fluid Recycling: By continuously circulating and recycling drilling fluids, the system minimizes the need for new chemicals and water. This not only conserves natural resources but also lowers operational costs associated with sourcing fresh supplies.

- Minimizing Waste: The system efficiently separates and removes drill cuttings, enabling them to be processed, stored, or disposed of more effectively. This reduces waste sent to landfills or hazardous disposal sites, minimizing material wastage.

- Optimized Energy Use: Modern mud circulation systems utilize energy-efficient pumps and motors that decrease overall power consumption during fluid circulation. This lowers energy demand in drilling operations, helping reduce greenhouse gas emissions.

By enhancing resource efficiency, the mud circulation system promotes the sustainable use of materials and energy, lessening the environmental impact of drilling activities.

Minimizing Environmental Impact

One of the key ways the mud circulation system contributes to sustainable drilling is by minimizing environmental impact. Traditional drilling methods often present risks of chemical spills and contamination due to improper handling of drilling fluids and waste materials. In contrast, modern mud circulation systems are designed to efficiently manage and recycle drilling fluids, significantly reducing the need for fresh water and chemicals.

- Recycling Drilling Fluids: By recycling drilling mud, these systems reduce waste volume, easing disposal challenges and lowering the need for new raw materials.

- Eco-Friendly Additives: Many modern drilling fluids incorporate biodegradable, non-toxic additives, such as plant-based polymers, which help protect ecosystems from the harmful effects of drilling activities.

- Reduced Spills and Contamination: Through advanced filtration and centrifugation, the mud circulation system effectively removes solids and purifies the fluid, reducing the likelihood of spills and contamination in surrounding areas.

These practices help lower the ecological footprint of drilling operations, fostering a more sustainable approach to energy extraction.

Improving Wellbore Stability and Safety

A stable wellbore is crucial for the safe and efficient drilling of oil and gas wells. Mud circulation systems play a vital role in maintaining pressure balance within the well, helping to prevent dangerous incidents such as blowouts and wellbore collapses.

- Hydrostatic Pressure Regulation: The mud circulation system ensures the required hydrostatic pressure is maintained in the wellbore, preventing the influx of fluids from surrounding formations. This pressure regulation is essential for wellbore stability and reduces the risk of uncontrolled gas or oil releases.

- Blowout Prevention: By controlling the flow of drilling fluid and maintaining stable pressure, the mud circulation system helps prevent blowouts, which can cause severe environmental damage. Blowouts are costly and pose significant safety risks to both the environment and drilling personnel.

- Real-Time Monitoring: Modern mud circulation systems are equipped with advanced sensors and monitoring technology that allow operators to detect pressure changes or fluid imbalances in real-time. This enables prompt corrective actions, enhancing safety throughout the drilling process.

By safeguarding wellbore integrity and preventing hazardous situations, the mud circulation system is essential in protecting both workers and the environment from the risks of drilling operations.

Technological Innovations in Mud Circulation Systems

Advances in mud circulation system technology have greatly improved its efficiency, sustainability and safety. Here are some of the key innovations shaping the future of drilling operations:

- Automated Monitoring Systems

Automated systems featuring sensors and real-time data analytics have transformed mud circulation operations. These systems continuously track key parameters such as fluid viscosity, temperature, and density. By gathering and analyzing data in real time, operators can make instant adjustments to maintain optimal fluid properties and reduce waste. Additionally, this automation minimizes human error, enhancing both safety and operational reliability.

- Advanced Centrifuge Technology

New centrifuge models are significantly more efficient at separating solids from drilling fluids. These high-speed separators allow for better recycling of drilling mud, reducing the need for new fluid and minimizing waste. With improved performance, centrifuges also extend the life of the fluid, lowering operational costs and further reducing environmental impact.

- Eco-Friendly Fluid Additives

The oil and gas industry is increasingly adopting eco-friendly additives to reduce the environmental impact of drilling fluids. Biodegradable polymers, plant-based additives, and non-toxic corrosion inhibitors are now being used in place of traditional chemical additives. These innovations lower toxicity levels and promote fluid reuse, making drilling operations more environmentally responsible.

- Simulation Technology

Simulation software is increasingly being used to model mud circulation systems and predict their behavior under various conditions. By creating virtual environments, operators can test new drilling techniques, optimize fluid management, and foresee potential challenges before they occur. This predictive capability helps reduce downtime, enhance system design, and improve overall efficiency.

These innovations are transforming the mud circulation system, making it a vital tool for sustainable and efficient drilling operations.

The mud circulation system is essential to modern drilling, allowing operators to ensure safety, efficiency, and sustainability. By utilizing advanced technologies and implementing eco-friendly practices, the oil and gas industry can reduce its environmental footprint while fulfilling global energy needs. As innovation advances, the mud circulation system will continue to be a pivotal force driving sustainable progress in the energy sector.