The Role of Artificial Intelligence in Optimizing Well Stimulation Techniques

In the oil and gas industry, well stimulation aims to increase the productivity of a reservoir by improving the flow of hydrocarbons to the surface. As operators continue to seek more efficient and cost-effective methods, the integration of advanced technologies such as artificial intelligence (AI) has become key to optimizing well stimulation techniques. AI’s ability to analyze large amounts of data, predict outcomes, and provide real-time solutions increases efficiency, reduces operating costs, and improves reservoir performance.

What are Well Stimulation Techniques

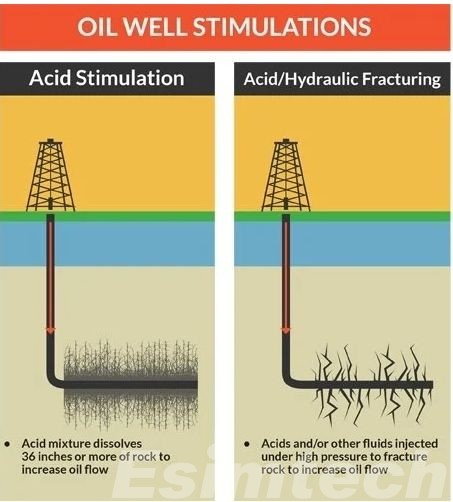

Well stimulation techniques are methods used to enhance the flow of hydrocarbons from a reservoir to the surface when natural production rates decline. Over time, reservoirs can experience reduced pressure or permeability issues, making it harder for oil and gas to flow freely. The most commonly used techniques in well stimulation include:

- Hydraulic Fracturing (Fracking): This technique involves injecting a high-pressure fluid into a well to create fractures in the surrounding rock formations. The fractures increase the reservoir’s permeability, enabling oil and gas to flow more easily toward the wellbore.

- Acidizing: Acidizing is the process of injecting a corrosive acid solution into the well to dissolve minerals such as limestone or sandstone that may be obstructing the reservoir. This technique enhances the rock’s permeability, improving the flow of hydrocarbons.

- Proppant Injection: Used alongside hydraulic fracturing, proppant injection introduces solid materials like sand or ceramic particles into the fractures created by fracking. These proppants keep the fractures open, allowing for more efficient flow of hydrocarbons.

These techniques have been vital in boosting well productivity, but their success depends on factors like proper design, reservoir characteristics, and precise execution.

Know the Role of AI and its Application In Oil and Gas

AI is transforming the oil and gas industry by providing advanced tools for data analysis, automation, and optimization. Its application in this sector helps operators make more informed decisions, improve efficiency, and reduce costs. Key roles of AI in the oil and gas industry include:

- Data Analysis: AI can process vast amounts of complex data from sensors, seismic surveys, and well performance reports. It uncovers hidden patterns and insights, enabling better decision-making.

- Predictive Maintenance: Machine learning models predict equipment failure before it occurs, allowing for proactive maintenance and minimizing downtime.

- Optimization of Operations: AI optimizes drilling and production processes, recommending adjustments based on real-time data to enhance productivity and reduce costs.

- Enhanced Reservoir Management: AI models help in understanding reservoir behavior, improving extraction strategies, and ensuring optimal resource recovery.

AI empowers operators to improve decision-making, reduce operational risks, and enhance overall productivity in the oil and gas sector.

AI Applications in Well Stimulation Optimization

AI technologies are transforming well stimulation optimization in several key ways. Here are the most important applications of AI in this area, each explained in greater detail:

Real-Time Data Analysis

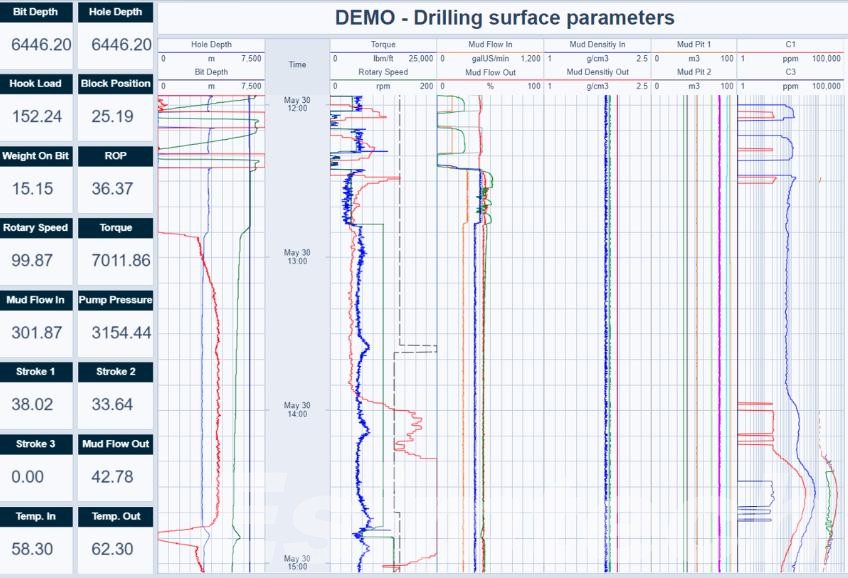

AI systems are capable of collecting and analyzing real-time data from sensors and monitoring devices installed within the well. This constant stream of data enables operators to make immediate adjustments to the stimulation process, ensuring optimal well performance while minimizing risks associated with delays or human error.

Real-Time Data

- Continuous Monitoring: AI processes data from multiple sources, such as pressure, temperature, and flow rates, to identify any abnormal conditions in real-time.

- Anomaly Detection: AI swiftly detects early signs of issues, such as formation damage or pressure irregularities, allowing operators to intervene immediately before problems worsen.

- Dynamic Adjustments: AI enables operators to adjust key parameters like fluid injection rates or proppant volumes in real time, optimizing the stimulation process based on current well conditions.

Predictive Analytics for Treatment Optimization

AI uses machine learning algorithms to process historical and real-time data to predict the outcomes of different stimulation techniques, such as hydraulic fracturing or acidizing, before they are applied. This predictive capability helps operators choose the most effective stimulation treatments for each specific well.

- Historical Data Integration: AI models incorporate data from past well performances, environmental conditions, and geological characteristics to understand which stimulation methods worked best.

- Treatment Success Prediction: AI forecasts the likely success of different stimulation methods based on a combination of past data, real-time inputs, and simulations of reservoir behavior.

- Minimized Risk: By accurately predicting the outcomes, AI reduces the trial-and-error nature of traditional well stimulation, lowering the financial and operational risks involved.

Automation and Control of Stimulation Processes

AI-powered automation tools are increasingly being used to manage various aspects of the well stimulation process, such as pressure control, fluid injection rates, and chemical treatments. By reducing human error, improving precision, and ensuring that stimulation parameters are continuously optimized, automation enhances the efficiency and reliability of the operation.

- Automatic Control Systems: AI-driven systems automatically adjust the injection of fluids and proppants based on real-time well conditions, optimizing pressure and flow rates without the need for manual intervention.

- Data-Driven Adjustments: These automated systems leverage AI to analyze data and make real-time adjustments to stimulation parameters, responding dynamically to changes in downhole conditions to maintain optimal performance.

- Consistency and Safety: AI-based automation ensures consistent application of well stimulation across multiple wells, reducing the potential for human error and significantly improving operational safety.

Oil and Gas Reservoir Simulation

AI enhances the ability to simulate and model the behavior of oil and gas reservoirs, providing valuable insights into how stimulation treatments will impact production over time. By integrating advanced AI algorithms with geological and reservoir data, operators can predict the effects of different stimulation methods on reservoir behavior, helping to optimize long-term recovery strategies.

- Dynamic Reservoir Modeling: AI allows for the creation of dynamic, real-time reservoir models that simulate fluid flow, pressure changes, and rock behavior under different stimulation scenarios. These models help engineers understand how the reservoir will respond to various treatments.

- Scenario Analysis: AI can evaluate multiple stimulation techniques and operational strategies by running various “what-if” scenarios, predicting how each approach will affect production rates, well longevity, and overall recovery efficiency.

- Improved Recovery Forecasting: By simulating the long-term effects of different stimulation methods, AI helps operators develop more accurate production forecasts, ensuring that decisions are based on data-driven insights rather than assumptions. This results in more efficient use of resources and better decision-making regarding well stimulation strategies.

Key Benefits of Using AI in Well Stimulation

The integration of AI in well stimulation brings several key benefits that significantly improve operational efficiency, reduce costs, and enhance well productivity. Below is a summary of these advantages:

| Benefit | Description |

| Cost Efficiency | AI optimizes stimulation techniques, reducing the need for trial-and-error and lowering overall costs. |

| Improved Well Productivity | By tailoring stimulation treatments, AI increases well performance and extends productive life. |

| Reduced Operational Risk | Real-time monitoring and adjustments with AI help prevent well damage and mitigate potential failures. |

| Faster Decision-Making | AI accelerates data analysis, enabling quicker, more accurate decisions to optimize stimulation methods. |

| Environmental and Safety Benefits | AI optimizes the use of chemicals and ensures better waste management, minimizing environmental impact. |

| Scalability | AI solutions are adaptable to multiple wells, offering consistent optimization across large-scale operations. |

Conclusion

Incorporating Artificial Intelligence into well stimulation techniques is transforming the oil and gas industry by enhancing efficiency, reducing costs, and improving well productivity. AI’ s ability to analyze data in real-time, predict outcomes, and optimize stimulation processes enables operators to make more informed decisions and minimize risks. As AI technology continues to evolve, its role in optimizing well stimulation will become even more critical, driving further advancements in the industry and contributing to more sustainable and cost-effective oil and gas production.