The Rise of “Green” Oil and Gas

The oil and gas industry, long demonized for its environmental impact, is facing an existential crisis. The global push towards renewable energy and the growing urgency to address climate change are putting immense pressure on the industry to change its ways. Enter the concept of “green” oil and gas, a paradoxical term that embodies the industry’s attempt to reconcile its traditional practices with the demands of a sustainable future.

So, what exactly is “green” oil and gas? It’s not a single technology, but rather a suite of strategies aimed at reducing the environmental footprint of oil and gas production and use.

Here we will come to see several main technologies.

Carbon Capture and Storage (CCS) Technology

Carbon Capture and Storage (CCS) is a three-pronged approach to mitigating climate change by capturing carbon dioxide (CO2) emissions from various sources and permanently storing them underground. Here’s a breakdown of the process:

Capture: CO2 emissions are captured from sources like power plants, steel mills, and refineries. Different methods exist, including chemical absorption, physical adsorption, and membrane separation.

Transport: The captured CO2, now in a concentrated form, is transported via pipelines or ships to storage locations.

Storage: The CO2 is injected deep underground into geological formations like depleted oil and gas reservoirs, saline aquifers, or basalts. These formations have favorable characteristics for safe and long-term storage, preventing the CO2 from escaping back into the atmosphere.

The benefits are:

Reduces greenhouse gas emissions: By capturing CO2, CCS directly addresses climate change by preventing its contribution to global warming.

Enables cleaner fossil fuel use: CCS can be integrated with existing power plants and industrial facilities, allowing them to continue operating while significantly reducing their carbon footprint. This is particularly relevant during the transition to renewable energy sources.

Potential for negative emissions: Combining CCS with bioenergy with carbon capture and storage (BECCS) can achieve negative emissions. BECCS involves capturing CO2 emitted during biomass plant operation and storing it underground, effectively removing CO2 from the atmosphere.

However, the Challenges are existing in these aspects:

Cost: Capturing, transporting, and storing CO2 is an energy-intensive process, making CCS a relatively expensive technology.

Storage security: Long-term storage effectiveness and potential leakage risks from geological formations require careful monitoring and mitigation strategies.

Public perception: Concerns exist about the safety and environmental impact of large-scale CCS projects, requiring transparent communication and public engagement.

Overall, CCS is a promising technology for mitigating climate change, but it’s crucial to weigh its benefits and challenges carefully. Ongoing research and development aim to address cost concerns, improve storage security, and ensure the responsible implementation of CCS projects.

Blue Hydrogen: Clean Fuel with a Caveat

1. Production Process:

Blue hydrogen, also known as low-carbon hydrogen, is produced primarily through steam methane reforming (SMR). This process involves the following steps:

- Natural gas preparation: The natural gas is pre-treated to remove impurities like sulfur compounds that can damage equipment or hinder downstream processes.

- Steam reforming: Preheated natural gas is mixed with high-temperature steam in the presence of a catalyst (usually nickel). This reaction breaks down the methane (CH4) in the natural gas into hydrogen (H2) and carbon monoxide (CO).

- Water-gas shift reaction: The CO from the reforming reaction reacts with additional steam in a separate step called the water-gas shift reaction, further converting CO into hydrogen and carbon dioxide (CO2).

- Carbon capture and storage (CCS): The CO2 generated during the SMR and water-gas shift reactions is captured using various technologies like chemical absorption or membrane separation. This captured CO2 is then transported via pipelines or ships to designated geological formations for permanent storage.

2. Environmental Impact:

Compared to traditional “grey” hydrogen production, which releases CO2 directly into the atmosphere, blue hydrogen boasts a significantly reduced carbon footprint due to CCS. However, it’s crucial to acknowledge the remaining environmental concerns:

- Upstream emissions: Natural gas extraction and transportation processes still generate greenhouse gas emissions, contributing to the overall carbon footprint of blue hydrogen.

- CCS effectiveness: The long-term effectiveness of CCS in permanently storing CO2 underground is still under investigation. Potential leaks from storage sites could negate the environmental benefits of capturing emissions.

- Energy consumption: CCS is an energy-intensive process, requiring additional energy input for capturing, transporting, and storing CO2. This additional energy demand can contribute to indirect emissions if sourced from non-renewable sources.

3. Future Outlook:

Blue hydrogen represents a potential bridge towards a clean hydrogen economy. However, its long-term viability depends on several factors:

- Cost reduction: Currently, blue hydrogen is more expensive than traditional methods due to the added cost of CCS technology. Advancements in CCS technology and economies of scale are essential for cost competitiveness.

- Renewable energy integration: The energy used for CCS can be sourced from renewable sources like solar or wind power to minimize the overall carbon footprint of blue hydrogen production.

- CCS infrastructure development: Building and expanding safe and reliable CCS infrastructure is crucial for large-scale deployment of blue hydrogen.

In conclusion, blue hydrogen offers a path towards cleaner hydrogen production, but it’s not without its complexities. Addressing the remaining environmental concerns, reducing production costs, and integrating renewable energy sources are critical steps for ensuring the sustainable future of blue hydrogen.

Bioenergy from Waste: Unlocking the Potential of Organic Waste

Bioenergy from waste offers a compelling solution for tackling multiple environmental challenges simultaneously. Here’s a deeper dive into this promising technology:

1. Conversion Technologies:

Bioenergy from waste utilizes various technologies to transform organic matter into usable fuels:

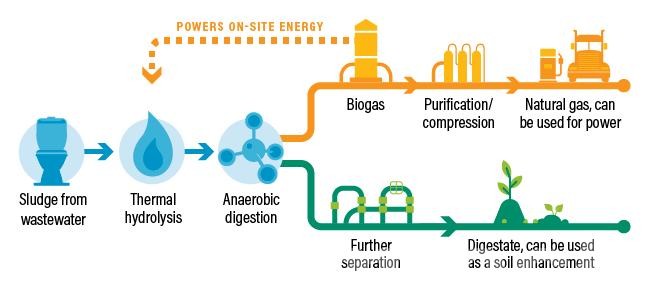

- Anaerobic Digestion: This process decomposes organic waste in the absence of oxygen, producing biogas, a mixture of methane (CH4) and carbon dioxide (CO2). Biogas can be burned directly for heat and electricity generation, upgraded to biomethane for use in natural gas pipelines, or converted into transportation fuels like compressed natural gas (CNG).

- Thermochemical Conversion: This approach utilizes high temperatures to convert organic waste into various biofuels. Examples include:

- Gasification: This process breaks down organic material in a controlled environment with limited oxygen, producing syngas, a mixture of hydrogen, carbon monoxide, and other gases. Syngas can be further processed into liquid transportation fuels like ethanol or methanol.

- Pyrolysis: Similar to gasification, pyrolysis decomposes organic material at high temperatures but in the absence of oxygen. This process yields bio-oil, a liquid fuel that can be used directly in boilers or upgraded to higher-quality fuels.

2. Benefits and Advantages:

- Waste Reduction and Diversion: Bioenergy from waste diverts organic materials from landfills, where they decompose anaerobically and generate potent greenhouse gases like methane. This approach reduces landfill reliance and associated environmental impacts.

- Renewable Energy Source: Biofuels derived from organic waste are considered renewable as they utilize organic matter that can be continuously replenished through natural processes or sustainable waste management practices.

- Circular Economy Contribution: Bioenergy from waste embodies the principles of a circular economy by transforming waste into a valuable resource. This approach promotes resource efficiency and reduces reliance on virgin materials.

- Additional Environmental Benefits: Compared to fossil fuels, biofuels from waste generally offer lower greenhouse gas emissions, especially when combined with efficient conversion technologies and sustainable feedstock management.

3. Challenges and Considerations

- Feedstock Availability and Sustainability: Ensuring a consistent and sustainable supply of organic waste feedstock is crucial for widespread adoption. Sourcing waste from diverse sources like food scraps, agricultural residues, and manure requires efficient collection and transportation systems.

- Technology Development: Advancements in conversion technologies are necessary to improve efficiency, cost-effectiveness, and scalability. Research and development efforts are ongoing to optimize existing technologies and explore novel approaches like hydrothermal liquefaction.

- Life Cycle Assessment: While biofuels from waste offer environmental benefits, a holistic life cycle assessment is essential to account for potential environmental impacts throughout the entire process, including feedstock cultivation, transportation, and emissions associated with conversion technologies.

Bioenergy from waste has the potential to play a significant role in transitioning towards a more sustainable future. As technology advances, costs decrease, and waste management practices improve, this approach can contribute to a cleaner energy future, waste reduction, and a more circular economy. However, continuous research, development, and responsible implementation are crucial to ensure the environmental and economic benefits of bioenergy from waste are fully realized.

Take “Green” Oil and Gas into Practice: Oil and Gas Simulation

The oil and gas industry is facing a pivotal moment. While traditionally a significant contributor to greenhouse gas emissions, the industry is increasingly seeking ways to reduce its environmental footprint. This is where “green” oil and gas comes in, focusing on innovative technologies and practices to minimize the environmental impact of the entire oil and gas value chain.

Simulation plays a critical role in taking “green” oil and gas from concept to reality. Here’s how:

1. Designing and optimizing low-carbon operations:

Carbon Capture and Storage (CCS): Simulation tools can be used to model the feasibility and efficiency of CCS projects. This includes simulating the injection process, reservoir behavior, and potential leakage risks, allowing for optimized design and risk mitigation.

“Blue” Hydrogen Production: Simulation helps optimize the “blue” hydrogen production process, ensuring efficient separation and capture of carbon dioxide while maximizing hydrogen yield.

Bioenergy from Waste Conversion: Simulation tools can model and optimize the conversion process of various waste streams into biofuels, considering factors like feedstock composition, reaction kinetics, and product purity.

2. Evaluating environmental impact:

Life Cycle Assessments (LCA): Simulation software can be used to conduct LCAs of different oil and gas production methods, including “green” alternatives. This allows for a comprehensive understanding of the environmental footprint at each stage of the process, from resource extraction to final product use.

Emissions Forecasting: Simulating production scenarios helps predict potential emissions associated with different “green” oil and gas strategies, enabling data-driven decision-making to minimize the environmental impact.

3. Optimizing resource use and reducing waste:

Reservoir Management: Simulation tools can help optimize reservoir management practices to minimize water usage and prevent wellbore leakage, leading to more efficient and environmentally friendly extraction.

Waste Management: Simulations can model and optimize waste treatment processes, such as produced water treatment and waste disposal, ensuring compliance with environmental regulations and minimizing environmental harm.

4. Training and upskilling the workforce:

Virtual Reality (VR) and Augmented Reality (AR): These technologies can be used to create immersive training simulations for personnel involved in “green” oil and gas operations. This allows for safe and efficient training on new technologies and procedures, ensuring proper implementation and reducing the risk of environmental incidents.

Conclusion

The rise of “green” oil and gas highlights the industry’s efforts to adapt to a changing world. While CCS, blue hydrogen, and bioenergy from waste offer promising avenues, they are not silver bullets. Continuous innovation, coupled with a strong commitment to renewable energy development, is essential for achieving a truly sustainable energy future. Ultimately, the question remains: can we have our cake and eat it too? Can we continue to rely on fossil fuels while minimizing environmental impact? The answer lies in a complex interplay of technological advancements, responsible resource management, and a clear vision for a cleaner future.