The Power of Gas Injection: A Critical Technique for Enhancing Oil Recovery

Gas injection is a pivotal enhanced oil recovery (EOR) technique in the oil and gas industry. It involves injecting gases into oil reservoirs to maintain pressure and enhance oil displacement, thereby maximizing hydrocarbon recovery. This method has become increasingly significant as conventional oil production methods reach their limits. This article delves into the mechanisms, types of gases used, benefits, challenges, and strategies of gas injection in the oil and gas industry, as well as how simulation technology is used in optimizing gas injection processes.

Mechanisms of Gas Injection

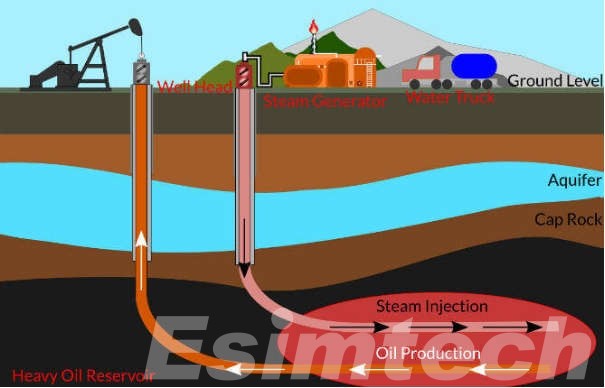

Gas injection works primarily through two mechanisms: pressure maintenance and miscible/immiscible displacement.

1. Pressure Maintenance

Injecting gas into a reservoir increases the overall pressure, helping to push oil towards production wells. This is particularly effective in reservoirs experiencing declining pressure due to prolonged extraction.

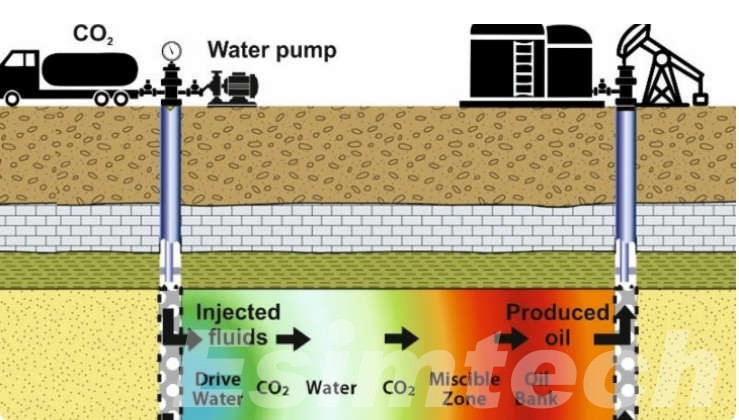

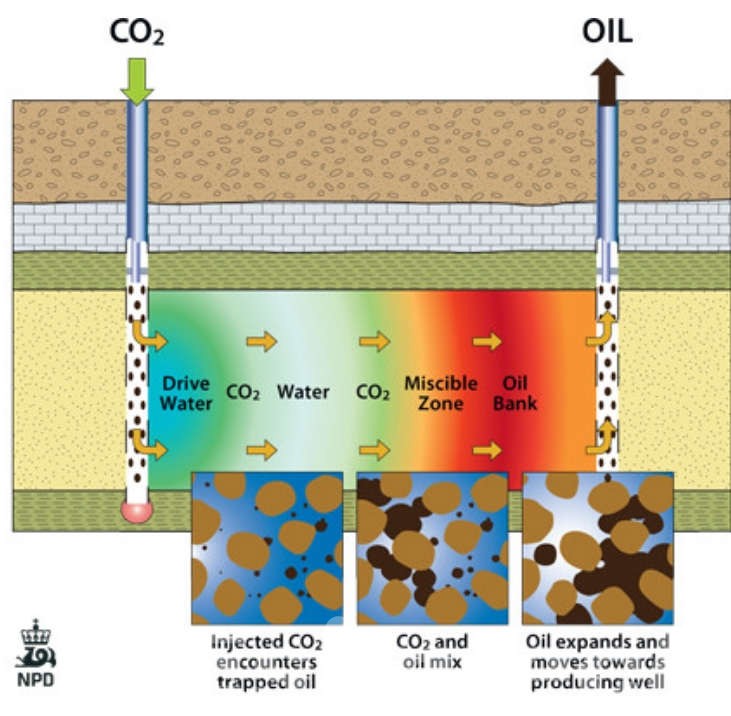

2. Miscible and Immiscible Displacement

- Miscible Gas Injection: When the injected gas mixes completely with the oil, it reduces the oil’s viscosity and interfacial tension, making it easier for the oil to flow through the reservoir rock. Common gases used for miscible injection include CO₂ and natural gas.

- Immiscible Gas Injection: If the gas does not mix with the oil, it creates a gas cap that pushes the oil toward production wells. Nitrogen and flue gases are typically used for immiscible injection.

Types of Gases Used

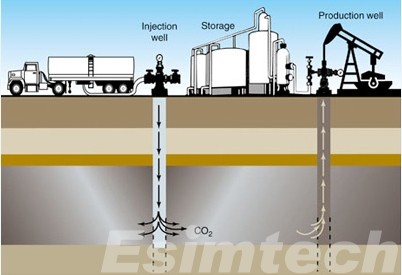

1. Carbon Dioxide (CO₂)

CO₂ is widely used due to its ability to mix with oil, reducing viscosity and improving flow. Additionally, CO₂ injection oil recovery helps in sequestering greenhouse gases, contributing to environmental sustainability.

2. Natural Gas

Natural gas, particularly methane, is used for its miscibility properties and availability. It is often reinjected into reservoirs to maintain pressure.

3. Nitrogen

Nitrogen is preferred for immiscible injection, especially in reservoirs where CO₂ or natural gas may not be effective. It is non-reactive and helps maintain reservoir pressure.

Key Benefits of Gas Injection in the Oil and Gas Industry

1. Enhanced Oil Recovery (EOR)

Increased Recovery Rates

- Gas injection can significantly boost the amount of oil that can be recovered from a reservoir. By injecting gas, oil that would otherwise remain trapped in the reservoir rock is mobilized and brought to the surface, thereby increasing the overall recovery factor.

- This method can recover an additional 5% to 20% of the original oil in place compared to primary and secondary recovery methods.

2. Pressure Maintenance

Reservoir Pressure Support

- Injecting gas helps maintain or increase the pressure within a reservoir. This pressure support is crucial for enhancing the flow of oil toward production wells, particularly in reservoirs where pressure has declined due to prolonged extraction.

- Maintaining reservoir pressure can also help stabilize production rates, delaying the natural decline in oil output.

3. Improved Oil Displacement

Reduced Oil Viscosity

- Gases such as CO₂ can mix with crude oil, reducing its viscosity. This makes the oil less sticky and easier to flow through the reservoir rock towards the production wells.

- Reduced interfacial tension between the oil and the rock further enhances oil mobility and displacement efficiency.

4. Cost Efficiency

Long-term Economic Benefits

- Although the initial setup for gas injection can be expensive due to the need for specialized equipment and infrastructure, the long-term economic benefits can outweigh these costs.

- By increasing the amount of recoverable oil, gas injection can significantly enhance the profitability of oil fields, extending their productive life and delaying decommissioning costs.

5. Environmental Benefits

Carbon Dioxide Sequestration

- CO₂ injection not only enhances oil recovery but also provides a means for carbon capture and storage (CCS). This process helps reduce greenhouse gas emissions by trapping CO₂ underground, preventing it from entering the atmosphere.

- This dual benefit makes CO₂ injection an attractive option for addressing climate change concerns while improving oil recovery.

Reduced Environmental Footprint

- Enhanced oil recovery through gas injection can reduce the need for drilling new wells, thereby minimizing the environmental impact associated with exploration and drilling activities.

6. Versatility and Adaptability

Suitable for Various Reservoir Conditions

- Gas injection techniques can be adapted to different types of reservoirs, including those with varying pressures, temperatures, and rock properties. This versatility makes it a valuable tool in the oil and gas industry.

- The method can be tailored to specific reservoir conditions to optimize oil recovery and address unique challenges.

7. Improved Reservoir Management

Enhanced Understanding of Reservoir Dynamics

- Implementing gas injection requires detailed reservoir modeling and monitoring, leading to a better understanding of reservoir dynamics. This enhanced understanding can improve overall reservoir management and optimize production strategies.

- Continuous monitoring and adjustment of injection parameters can help maximize recovery efficiency and minimize operational risks.

Challenges and Strategies for Gas Injection in the Oil and Gas Industry

This chart provides a concise overview of the main challenges associated with gas injection and the corresponding strategies to address them, along with the benefits of implementing these strategies.

| Challenges | Description | Strategies | Benefits |

| Reservoir Heterogeneity | Complex geological formations with varying permeability and porosity | Enhanced reservoir characterization using advanced geophysical techniques | Improved reservoir models for better planning and optimization |

| Gas Channeling and Breakthrough | Gas takes the path of least resistance, leading to early breakthroughs at production wells | Optimized injection strategies, such as Water Alternating Gas (WAG) injection | Reduces gas channeling and improves overall oil recovery |

| High Operational Costs | Significant investment in infrastructure such as compressors, pipelines, and injection wells | Conduct detailed economic feasibility studies and apply cost-effective technologies | Ensures financial viability of gas injection projects |

| Gas Availability and Supply | Challenges in sourcing and transporting gases like CO₂ or nitrogen | Develop robust logistics and supply chains for consistent gas supply | Ensures uninterrupted injection operations |

| Corrosion and Equipment Integrity | The corrosive nature of gases like CO₂ can damage wellbore and surface equipment | Use corrosion-resistant materials, apply protective coatings, and perform regular maintenance | Extends equipment lifespan and reduces risk of failure |

| Environmental and Regulatory Concerns | Strict regulations regarding gas injection and CO₂ sequestration | Work closely with regulatory bodies and adopt best environmental practices | Minimizes legal risks and enhances project sustainability |

| Monitoring and Control | Need for accurate monitoring and control of the injection process | Deploy real-time monitoring systems and advanced control technologies | Enhances precision of injection process and improves recovery rates |

How Simulation Technology is Used in Optimizing Gas Injection in the Oil and Gas Industry

Simulation technology enables accurate modeling of reservoir behavior, prediction of gas injection outcomes, and efficient planning and management of Enhanced Oil Recovery operations.

1. Reservoir Modeling

Geological Modeling

- Simulation software constructs detailed geological models of reservoirs based on seismic data, well logs, and core samples.

- These models represent the reservoir’s heterogeneity, including variations in porosity, permeability, and fluid saturations.

Dynamic Reservoir Simulation

- Once geological models are in place, dynamic simulations are conducted to predict how the reservoir will respond to gas injection over time.

- These simulations account for fluid flow, pressure changes, and gas-oil interactions.

2. Injection Strategy Optimization

Scenario Analysis

- Oil recovery simulation allows for the testing of various gas injection scenarios, such as different injection rates, patterns, and gas types (e.g., CO₂, nitrogen, natural gas).

- By comparing these scenarios, operators can identify the most effective strategy for maximizing oil recovery.

Water Alternating Gas (WAG) Injection

- Simulations help design and optimize WAG injection schedules, balancing the injection of water and gas to improve sweep efficiency and minimize gas channeling.

3. Predictive Analytics

Forecasting Performance

- Simulation technology forecasts the long-term performance of gas injection projects, estimating future production rates and recovery factors.

- This helps in planning and budgeting by providing insights into the expected return on investment.

Risk Assessment

- Potential risks, such as gas breakthrough and uneven reservoir sweep, are identified and mitigated through predictive simulations.

- Operators can develop contingency plans based on simulation outcomes.

4. Real-Time Monitoring and Adjustments

Integration with Real-Time Data

- Modern oil and gas simulation tools can integrate real-time data from the field, such as pressure and production rates, to continuously update the reservoir model.

- This enables real-time monitoring and adjustment of gas injection parameters to optimize performance.

Adaptive Control

- Adaptive control algorithms, informed by simulations, allow for dynamic adjustments to injection strategies based on real-time reservoir conditions.

- This ensures that the injection process remains efficient and responsive to changing reservoir dynamics.

5. Environmental Impact Assessment

CO₂ Sequestration Modeling

- For CO₂ injection projects, simulations model the behavior of CO₂ within the reservoir, ensuring safe and effective sequestration.

- These models help predict the long-term stability of sequestered CO₂ and assess the potential for leakage.

Regulatory Compliance

- Simulation technology aids in demonstrating compliance with environmental regulations by providing detailed reports on reservoir behavior and gas movement.

- This is crucial for gaining approval for gas injection projects and for ongoing regulatory reporting.

6. Economic Evaluation

Cost-Benefit Analysis

- Economic simulations evaluate the cost-effectiveness of different gas injection strategies, factoring in operational costs, projected production increases, and market conditions.

- This helps operators make informed decisions about the feasibility and potential profitability of gas injection projects.

Optimization of Resources

- By predicting the outcomes of various scenarios, simulations ensure that resources are used efficiently, reducing waste and maximizing the economic return.

Conclusion

Gas injection is a critical technique in the oil and gas industry, enhancing oil recovery and extending the productive life of reservoirs. While the method offers numerous benefits, including increased recovery rates and environmental advantages, it also presents technical, economic, and environmental challenges. By adopting advanced reservoir characterization techniques, optimizing injection strategies, managing costs, ensuring reliable gas supply, addressing corrosion issues, complying with regulations, and implementing advanced monitoring systems, operators can overcome these challenges.

Simulation technology is an indispensable tool in the oil and gas industry for optimizing gas injection processes. Through the use of advanced simulation tools, operators can maximize oil recovery, mitigate risks, and achieve better overall project outcomes.