The Importance of Rig Selection in Top Hole Drilling Operations

In the world of oil and gas drilling, top hole drilling is a critical stage in the well construction process. It involves drilling the initial section of the wellbore, which establishes a foundation for subsequent drilling operations and ensures the structural integrity of the well. Rig selection plays a pivotal role in the success of top hole drilling, influencing operational efficiency, safety, and cost-effectiveness.

What is Top Hole Drilling in Oil and Gas

Top hole drilling is the first and one of the most essential phases of well construction. It involves drilling the uppermost section of the wellbore, which serves as the foundation for the entire drilling operation. The success of this stage directly impacts the stability and integrity of the well throughout its lifecycle. Key objectives of top hole drilling include:

- Establishing Structural Stability: By installing surface casing, this phase ensures the wellbore is reinforced, preventing collapses and isolating unstable formations near the surface.

- Preparing for Well Control: Top hole drilling provides the necessary groundwork for installing blowout preventers (BOPs), enabling safe and effective pressure management in deeper drilling operations.

- Managing Unique Formation Challenges: The shallow depths of the top hole often feature loose, soft, or unstable formations. Proper techniques and equipment are required to drill through these zones safely and efficiently.

Given its foundational nature, top hole drilling demands specialized equipment and methods to ensure operational efficiency, minimize risks, and provide a solid base for the next stages of drilling.

Types of Rigs for Top Hole Drilling

Selecting the appropriate rig for top hole drilling is crucial to the success and efficiency of operations. Different types of rigs are suited to various drilling environments and project requirements. Here are the primary rig types used in top hole drilling:

Selecting the appropriate rig for top hole drilling is crucial to the success and efficiency of operations. Different types of rigs are suited to various drilling environments and project requirements. Here are the primary rig types used in top hole drilling:

1. Land-Based Rigs

Land rigs are a staple for onshore top hole drilling, offering versatility in size and capacity to suit a wide range of geotechnical conditions. Portable or mobile land rigs are especially advantageous in remote areas, thanks to their ability to be disassembled and transported with ease. Many of these rigs come equipped with specialized systems designed to handle large-diameter casings and address the challenges posed by soft or unstable formations commonly found in the upper sections of a well.

2. Modular Rigs

Modular rigs are specifically designed to operate in remote and demanding environments, such as arctic or mountainous regions. Built in transportable modules, they can be easily moved and assembled on-site, making them an ideal choice for areas with limited infrastructure. These rigs often feature advanced automation and monitoring systems, boosting efficiency and safety during top hole drilling operations.

3. Jack-Up Rigs

In offshore environments, jack-up rigs are frequently employed for top hole drilling in shallow waters. These rigs have legs that can be jacked down to the seabed, providing a stable platform for drilling. Their ability to handle large loads and maintain stability in marine conditions makes them ideal for installing surface casings and preparing the well for deeper offshore drilling phases.

4. Specialized Top Hole Rigs

Some rigs are purpose-built for top hole drilling, offering enhanced mobility and optimized features for shallow and large-diameter drilling. These rigs may include custom mud circulation systems and cutting-edge automation technologies to improve performance and reduce environmental impact.

Selecting the right rig depends on key factors such as the drilling location, environmental conditions, and the scale of the project, highlighting the importance of careful planning in top hole operations.

Key Factors of Rig Selection in Top Hole Drilling Operations

Choosing the right rig for top hole drilling is a critical decision that directly impacts the efficiency, safety, and success of the operation. The following four factors are the most important considerations when selecting a rig for top hole drilling.

Rig Capacity and Capability

The rig’s capacity is a critical factor in top hole drilling. It must be powerful enough to meet the specific demands of drilling the well’s initial section, including handling large-diameter casing and heavy-duty equipment. Top hole drilling often requires passing through soft or unconsolidated formations, which may necessitate specialized rigs capable of managing high mud weights and efficiently circulating drilling fluid to prevent blowouts or wellbore instability. The rig’s hoisting capacity must also be adequate to support the weight of the equipment, particularly when running casing to greater depths. Furthermore, the rig should be equipped with reliable drilling mud systems to handle the high-volume circulation needed for clearing cuttings and maintaining wellbore stability.

Mobility and Location Flexibility

Top hole drilling is often conducted in remote or offshore locations where mobility and quick setup are crucial. The ability to rapidly move and deploy a rig can significantly reduce non-productive time (NPT) and improve cost-efficiency. For onshore projects, modular rigs that can be easily disassembled and transported are ideal, enabling faster relocation. In offshore operations, jack-up or semi-submersible rigs are commonly used for their stability and ability to function in challenging sea conditions. Additionally, the choice of rig must account for logistical factors such as terrain access, transport routes, and the availability of support infrastructure.

Geological and Geotechnical Considerations

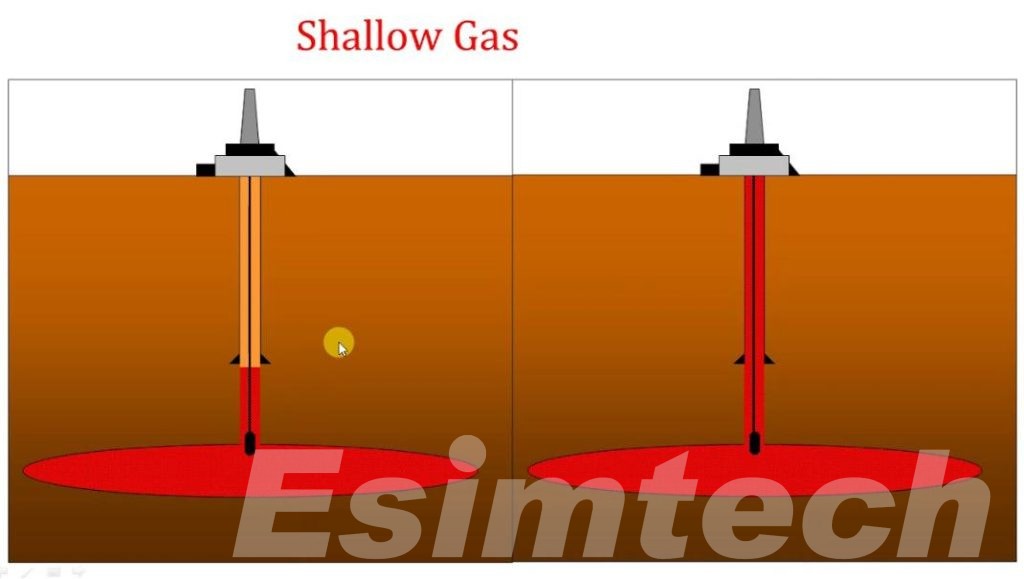

The geotechnical conditions of the formation being drilled play a crucial role in rig selection. Top hole drilling often involves passing through a range of rock formations, from soft sediments to harder strata, each with varying degrees of stability. A rig chosen for top hole drilling must be adaptable to these diverse geological conditions, including unstable formations that may require additional casing to prevent collapse or address hazards such as gas pockets. The rig must also be capable of handling challenges like high-pressure zones or lost circulation, which are common in the upper part of the wellbore. Rigs equipped with advanced mud management systems, specialized drilling motors, and adjustable weight-on-bit controls are essential for effectively managing these geological complexities.

Safety and Environmental Considerations

Safety is a top priority in top hole drilling, as the initial phase often involves unpredictable geological formations and surface-level hazards. Rigs equipped with automated systems, such as pipe-handling automation, blowout preventers (BOPs), and real-time monitoring, can significantly reduce the risk of accidents and enhance operational safety. Alongside safety, environmental regulations must also be considered. Rigs should meet emissions standards, waste disposal requirements, and other environmental guidelines to minimize their impact on the surrounding ecosystem. Features like low-emission engines, efficient waste management systems, and spill containment measures are increasingly essential for ensuring the sustainability of drilling operations while complying with regulatory standards.

Best Practices for Rig Selection in Top Hole Drilling Operations

Selecting the right rig for top hole drilling operations is crucial for ensuring efficiency, safety, and cost-effectiveness. To make an informed decision, several best practices should be followed:

- Comprehensive Assessment of Geological Conditions: Before selecting a rig, thoroughly analyze the geological formations expected in the top hole section. Understand factors like rock hardness, formation stability, and the likelihood of encountering gas pockets or other hazards. This will help determine the required rig capacity and the type of drilling tools needed.

- Prioritize Rig Flexibility and Adaptability: Choose rigs that are flexible and capable of adapting to varying geological conditions. This includes having sufficient hoisting capacity, mud circulation systems, and adjustable weight-on-bit controls. Rigs with advanced directional drilling capabilities can also be beneficial if deviations are necessary.

- Evaluate Mobility and Setup Efficiency: In remote or offshore environments, rig mobility and ease of setup are critical. Modular rigs that can be quickly mobilized or jack-up rigs for offshore projects help minimize downtime and reduce costs associated with transportation and setup.

- Focus on Safety and Environmental Impact: Ensure the rig is equipped with advanced safety systems like automated pipe handling, blowout preventers (BOPs), and real-time monitoring. Additionally, choose rigs that comply with environmental standards to minimize emissions and waste, reducing the overall environmental footprint.

Following these best practices ensures a successful top hole drilling operation with minimal risk and optimal performance.

Conclusion

In conclusion, selecting the right rig is essential for successful top hole drilling. The rig must align with geological conditions, operational needs, and safety standards to ensure efficiency and reduce risks. With advancements in technology and a focus on sustainability, rig selection remains critical for laying a strong foundation for deeper drilling and achieving overall project success.