The Impact of Directional Core Drilling on Oil and Gas Exploration

Oil and gas exploration has evolved immensely over time, with innovative technologies enabling more precise resource extraction. One such innovation is directional core drilling, which has revolutionized this industry by improving resource recovery rates, decreasing environmental impact, and optimizing drilling operations. This article investigates its role in oil and gas exploration as well as its economic and operational advantages.

What is Directional Core Drilling?

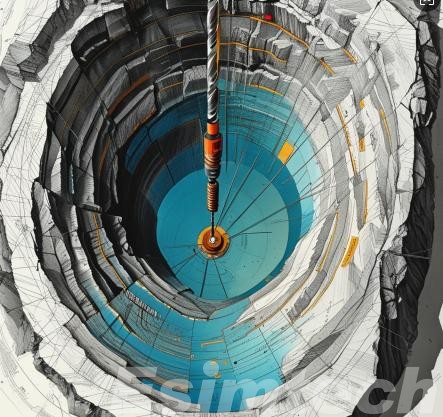

Directional core drilling is an advanced oil and gas exploration technique used to extract core samples from subsurface formations at precise angles. As opposed to traditional vertical drilling techniques that follow a straight path, directional core drilling allows operators to steer the drill bit to reach targeted reservoirs under obstacles like bodies of water, urban areas or environmentally sensitive zones.

Directional core drilling is an indispensable technique for collecting high-quality core samples that provide valuable geological data, including rock composition, fluid content and reservoir characteristics. By providing access to deeper formations directional core drilling allows reservoir evaluation for more accurate resource evaluation and reduces surface disturbance as multiple targets can be reached from one drilling site thereby lowering operational costs thereby making an invaluable contribution toward increasing efficiency, safety and sustainability within modern oil and gas exploration.

The Role of Directional Core Drilling in Oil and Gas Exploration

Directional core drilling has revolutionized oil and gas exploration by providing more accurate resource identification, increasing extraction efficiency and decreasing environmental impact. Here are four ways it plays an integral part in this industry.

1. Improved Reservoir Characterization and Data Collection

One of the key challenges in oil and gas exploration is understanding the geology of a reservoir before drilling commences. With directional core drilling, geologists are able to gather samples from various angles and depths that provide a more comprehensive view of rock formation, fluid composition, porosity and porosity in order to make informed decisions regarding drilling locations, hydrocarbon reserves estimation, production potential projections as well as risk reduction plans with maximum efficiency in mind.

2. Increased Safety and Decreased Operational Risks

Drilling operations often pose considerable safety risks, such as well blowouts, equipment failures, geological instabilities, and geological shifts. Directional core drilling helps mitigate these risks by offering more controlled well trajectories, which reduce the chances of accidentally drilling into unstable formations or high-pressure zones. Furthermore, its relief well drilling capability enables operators to drill relief wells precisely targeting affected areas in case of emergencies such as uncontrolled blowouts; ultimately this proactive approach significantly reduces risks while simultaneously protecting both workers and the environment from accidents.

3. Reaching Hard-to-Reach and Complex Reservoirs

Oil and gas deposits often exist in challenging environments such as bodies of water, mountains or urban centers where traditional vertical drilling would be impractical or impossible. Directional drilling makes these reservoirs accessible by steering the drill bit around obstacles or at extended horizontal angles to reach them more quickly and more effectively than would traditional vertical drilling alone. Furthermore, its ability to tap multiple hydrocarbon zones from one wellbore increases recovery efficiency while decreasing site requirements – especially beneficial when offshore drilling where infrastructure and footprint reduction are key considerations – further making its use even more compelling when offshore drilling where infrastructure and surface footprint reduction are paramount.

4. Minimizing Environmental Impact and Surface Disruption

Oil and gas exploration often raises eyebrows because of its environmental footprint, especially if it results in significant land use and habitat disturbance. To minimize these negative impacts and surface disruption, companies need to find ways to minimize their environmental footprint as much as possible. Directional drilling offers an effective solution to these concerns by permitting multiple wells to be drilled from one pad, thus decreasing the number of drilling sites and minimising surface disturbance. Directional drilling can be especially useful in environmentally sensitive regions such as protected lands or offshore regions where ecological disruption is of primary concern. Furthermore, by improving drilling efficiency and decreasing the number of required wells required for exploration activities, directional drilling leads to lower carbon emissions and waste production and supports more eco-friendly exploration practices.

These qualities make directional core drilling an indispensable asset in modern oil and gas exploration, helping companies extract resources efficiently while upholding environmental and safety regulations.

Technological Innovations Driving Directional Core Drilling

Recent technological developments have greatly enhanced the accuracy, efficiency, and cost-effectiveness of directional core drilling operations. Here are a few innovations shaping oil and gas exploration:

1. Measurement While Drilling (MWD) & Logging While Drilling (LWD)

MWD and LWD tools offer real-time data on subsurface conditions, including rock formations, pressure levels, fluid properties, and fluid dynamics – providing real-time data that allows operators to make instantaneous adjustments for optimal wellbore placement while reducing drilling errors.

2. Rotary Steerable Systems (RSS)

RSS technology offers accurate directional control without interrupting drilling operations, constantly adjusting the drill bit’s trajectory and improving accuracy, wellbore stability and overall efficiency.

3. 3D Seismic Imaging

Advanced seismic imaging techniques, including 3D and 4D seismic surveys, enable geologists to map underground reservoirs with great precision. When combined with directional drilling strategies, companies can target highly productive zones while simultaneously avoiding geological hazards.

4. Simulation Drilling Technology

Simulation Drilling Technology utilizes advanced modeling software and artificial intelligence to simulate actual drilling operations before beginning, helping engineers anticipate challenges, optimize drilling paths and refine well designs, while simultaneously lowering operational risks and costs.

5. Automation and AI Integration

Artificial intelligence and automation are revolutionizing directional core drilling by providing predictive maintenance, optimizing parameters, and reducing human error. AI-powered algorithms analyze large volumes of data for better decision making to ensure more sustainable drilling operations.

Due to advances in technology, directional core drilling continues to advance with improved resource recovery rates, reduced costs, and minimal environmental impacts for oil and gas exploration.

Economic and Operational Advantages

Directional core drilling offers significant economic and operational advantages that help boost oil and gas exploration operations. By facilitating precise well placement and optimized resource extraction, this technology helps companies reduce costs, boost production rates, increase sustainability, and enhance profitability.

1. Lower Drilling Costs: Directional core drilling reduces drilling costs by eliminating the need for multiple vertical wells by enabling operators to access multiple reservoirs via one wellbore, thus cutting expenses related to rig operation, manpower, and materials while ultimately lowering per barrel costs of oil extracted.

2. Faster and Efficient Operations: Advanced drilling technologies like real-time monitoring and automation provide advanced drilling systems with the capabilities of optimizing drilling performance by minimizing downtime and increasing efficiency, ultimately speeding up project completion while increasing return on investment faster.

3. Increased Hydrocarbon Recovery: Directional drilling provides access to previously inaccessible reserves, increasing reservoir contact and hydrocarbon drainage rates to boost recovery rates resulting in greater production output and extended well lifespans, thus making exploration more lucrative.

4. Environmental and Regulatory Compliance: Directional core drilling provides companies with an effective means of meeting environmental regulations while running efficient operations, thus contributing to sustainability as well as strengthening a company’s image in its industry. This improves sustainability while simultaneously strengthening company reputation.

Conclusion

Directional core drilling has become an indispensable tool in modern oil and gas exploration, offering enhanced reservoir access, increased efficiency and reduced environmental impact. Through technological innovations, directional core drilling will continue to shape its industry’s future by optimizing operations and increasing resource recovery – becoming more crucial as energy demand increases than ever. As demand for energy increases so too will directional core drilling remain one of the primary methods of sustainable hydrocarbon exploration.