The Essential Role of Density Logging in Effective Reservoir Evaluation

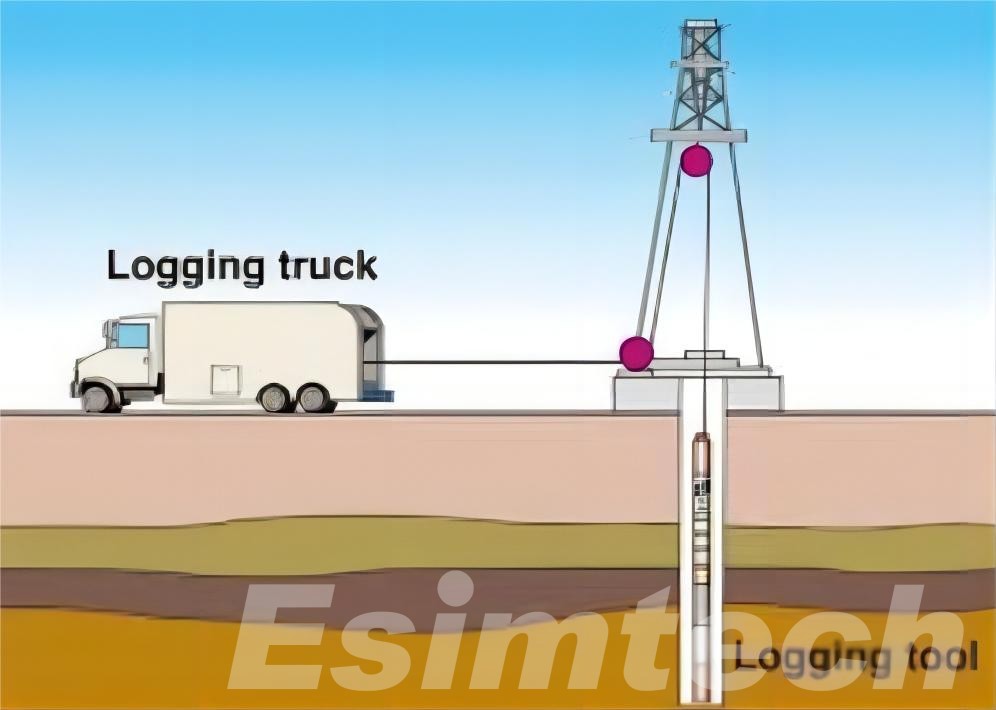

Density logging is an essential technique in the oil and gas industry. By measuring the bulk density of subsurface formations, this method provides critical insights into the geological structure, helping in reservoir characterization, formation evaluation, and resource estimation.

What is Density Logging

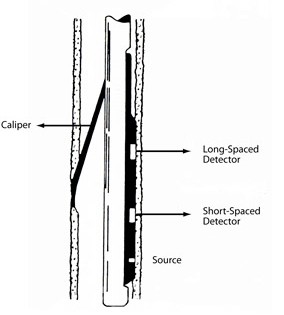

Density logging is a type of well logging that measures the electron density of rock formations surrounding a borehole. This is achieved using a tool known as a gamma-gamma density logger, which emits gamma rays into the formation and detects the gamma rays scattered back to the tool. The amount of scattered radiation depends on the density of the surrounding rock.

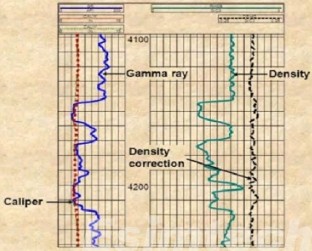

By correlating the amount of scattering with rock density, operators can determine the bulk density of the formation. The bulk density is a combination of the rock matrix density, pore fluid density, and porosity, offering a comprehensive understanding of the geological features encountered.

How Does Density Logging Work in Oil and Gas Exploration

This chart summarizes the key steps in how density logging functions in oil and gas exploration.

| Process Step | Description |

| 1. Gamma Ray Emission | The logging tool emits high-energy gamma rays into the rock formation surrounding the borehole. |

| 2. Gamma Ray Scattering | Gamma rays interact with electrons in the rock, with denser formations causing more scattering of the rays. |

| 3. Detection of Scattered Gamma Rays | Detectors in the tool measure the scattered gamma rays that return to the tool, indicating formation density. |

| 4. Bulk Density Calculation | The tool calculates the bulk density of the formation based on the intensity of the scattered gamma rays. |

| 5. Real-Time Data Transmission | The density data is transmitted to the surface in real-time for analysis and recording. |

| 6. Porosity Estimation | By comparing the bulk density with the known rock matrix density, the porosity of the formation is estimated. |

| 7. Lithology and Fluid Content Identification | The density log is analyzed alongside other logs to determine rock types and fluid content (oil, gas, water). |

| 8. Borehole Condition Corrections | Corrections are applied for borehole conditions such as mudcake and tool standoff to improve data accuracy. |

Key Applications of Density Logging in the Oil and Gas Industry

1. Porosity Determination

One of the most critical applications of density logging in oil and gas exploration is the determination of porosity. By comparing the bulk density of the formation with the known matrix density, the porosity of the rock can be estimated. Porosity is a key indicator of a reservoir’s capacity to store hydrocarbons, making it vital for evaluating the potential of an oil or gas field.

2. Lithology Identification

Density logging helps in identifying the types of rock present in the subsurface. Different rocks have distinct density signatures; for instance, sandstone, limestone, and shale each have different density ranges. By analyzing the density log, geologists can differentiate between these rock types, aiding in the understanding of reservoir structures and fluid flow paths.

3. Fluid Saturation and Hydrocarbon Indicators

When combined with neutron or resistivity logs, density logs help to distinguish between different fluid types—such as oil, gas, and water. This is done by comparing the bulk density with the porosity and fluid saturation data, providing an estimate of hydrocarbon saturation in the formation. This combination of data enables a more accurate assessment of the economic potential of the reservoir.

4. Estimation of Formation Compaction and Mechanical Properties

Density logs provide insight into the compaction of sediments, which is critical for understanding the mechanical properties of the formation. This information helps drilling engineers assess wellbore stability and predict potential issues such as wellbore collapse or sand production. Additionally, it assists in the design of casing and cementing programs, ensuring the integrity of the well.

5. Reservoir Delineation

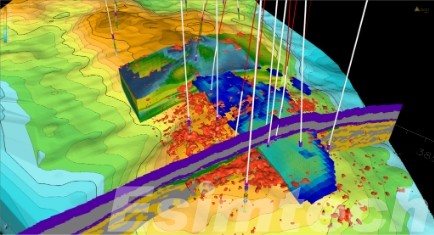

Density logging is also used to delineate reservoir boundaries by identifying zones with varying densities. For example, denser layers may indicate impermeable formations, while less dense layers with higher porosity could signify productive reservoir zones. This detailed formation analysis is essential for optimal well placement and completion strategies.

Advantages of Density Logging in Oil and Gas Industry

- Accurate Porosity Calculation: Density logging provides reliable data for calculating porosity, which is crucial for estimating reservoir capacity and productivity.

- Non-Invasive and Real-Time Measurements: The technique is non-destructive, allowing continuous and real-time measurement of subsurface properties without the need to retrieve core samples.

- Effective Integration with Other Logs: When combined with other logging methods such as neutron, sonic, or resistivity logs, density logs provide a comprehensive understanding of the formation, improving the accuracy of reservoir models.

- Versatility in Different Formation Types: Density logging is effective across a wide range of geological settings, making it suitable for use in various environments, from deep offshore wells to complex, onshore reservoirs.

Challenges and Innovative Solutions in Density Logging

This chart highlights how innovative solutions are addressing key challenges in density logging, leading to more accurate and efficient subsurface formation evaluation.

| Challenges | Description | Solutions |

| Borehole Washouts and Irregularities | Enlarged or irregular boreholes can cause inaccurate density readings by increasing the distance between the tool and the formation. | Use of advanced correction algorithms to compensate for wellbore conditions and irregular shapes. |

| Mudcake Buildup | A layer of mudcake on the wellbore wall can interfere with density measurements, leading to skewed results. | Implementation of mudcake correction techniques to ensure more accurate density measurements. |

| Tool Standoff Issues | Variations in the tool’s distance from the borehole wall (standoff) affect the accuracy of gamma ray detection. | Proximity sensors integrated into tools to reduce errors caused by variations in tool standoff from the borehole wall. |

| Formation Heterogeneity | Variations in rock properties within a formation can make it difficult to obtain consistent density data. | High-resolution multi-sensor tools to capture detailed information across varying formations. |

| Limited Depth of Investigation | Density logging tools often measure only the near-wellbore region, which may not represent deeper formation properties. | Development of deep-reading tools to capture more representative formation density beyond near-wellbore zones. |

| Borehole Fluid Interference | Fluids in the borehole can scatter gamma rays and distort the density readings of the surrounding rock. | Advanced fluid correction algorithms to minimize the influence of borehole fluids on density measurements. |

| Complex Data Interpretation | High-density rock formations, mixed lithologies, and borehole conditions make density logs difficult to interpret accurately. | Use of machine learning and AI for enhanced data analysis, helping interpret complex logs more efficiently. |

| Time-Intensive Logging Operations | Logging operations can be time-consuming, especially in deep wells or under challenging borehole conditions. | Real-time data transmission and automated processing systems to speed up logging and decision-making. |

How Simulation Technology is Used in Density Logging

Oil and gas simulation technology plays a critical role in enhancing the accuracy, efficiency, and reliability of density logging.

1. Tool Design and Calibration

- Virtual Tool Prototyping: Simulation technology allows engineers to design and virtually test density logging tools under different borehole and formation conditions. This reduces the need for physical prototypes, accelerating tool development.

- Calibration Simulations: Before deployment, density logging tools are calibrated in virtual environments that replicate specific geological conditions. This ensures that the tools perform accurately in real-world applications.

2. Training for Operators

- Training Simulators: Simulators replicate real-world logging operations, helping engineers and geologists practice tool deployment and data interpretation. These training programs enhance proficiency without the risks and costs associated with field training.

- Realistic Scenarios: Simulation environments can replicate various challenges such as borehole irregularities, high-pressure environments, and tool malfunctions, allowing operators to develop problem-solving skills in a controlled environment.

3. Data Interpretation and Validation

- Synthetic Log Generation: Simulated data is generated based on geological models and tool responses. This synthetic data helps verify the accuracy of the real density logs, ensuring better data interpretation.

- Predictive Models: Advanced simulations create predictive models of rock formations, enabling geologists to compare real density logs with simulated results. This helps in validating formation properties like porosity and lithology.

4. Borehole Condition Simulations

- Simulation of Borehole Environments: Borehole conditions like washouts, mudcake buildup, and borehole fluid interference can be simulated, allowing operators to predict their effects on density readings and apply correction factors more accurately.

- Testing Extreme Conditions: Simulations model extreme temperature, pressure, and environmental conditions, ensuring the logging tool’s performance is reliable in harsh drilling environments.

5. Formation Evaluation Models

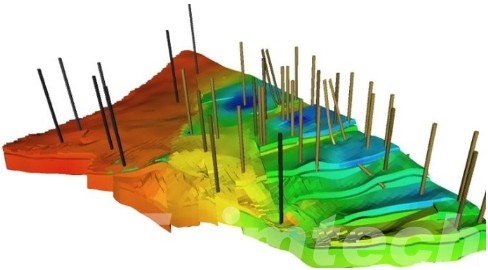

- Reservoir Characterization: Simulations model how density logging tools interact with different rock types and formations. These models help predict formation characteristics, leading to better reservoir evaluation.

- Cross-Validation with Other Logs: Simulation technology allows density log data to be compared with other logs (e.g., neutron or resistivity logs) in a virtual environment, helping to refine estimates of formation properties such as porosity and fluid content.

6. Real-Time Data Processing

- Simulated Real-Time Environments: By simulating real-time logging operations, engineers can optimize data transmission, processing, and interpretation workflows. This leads to faster decision-making during logging operations.

- Predictive Analytics: Simulation technology helps apply predictive analytics to real-time data, anticipating potential issues such as tool malfunction or unexpected formation properties before they impact operations.

In summary, By providing precise measurements of formation density, density logging helps operators make informed decisions about drilling, production, and field development. With continuous advancements in logging technology, density logging will continue to play a key role in optimizing hydrocarbon exploration and ensuring the efficient extraction of resources from complex reservoirs.