The Critical Role of Reservoir Simulation Software in the Oil and Gas Industry

Reservoir simulation software plays a crucial role in the oil and gas industry, allowing engineers and geoscientists to model, analyze, and predict the behavior of hydrocarbon reservoirs. By using advanced computational techniques, the oil and gas software provides insights into how a reservoir will respond to different extraction methods, allowing for optimized field development and improved recovery strategies.

What is Reservoir Simulation Software

Reservoir simulation software is a sophisticated tool that models the physical processes within oil, gas, and water reservoirs. It provides a virtual environment where the interaction of fluids, pressure, temperature, and geological formations can be simulated to predict the performance of a reservoir under different production strategies.

These reservoir simulations are based on mathematical models and algorithms that incorporate data from various sources, such as seismic surveys, well logs, core samples, and production history. The goal is to create an accurate representation of the reservoir’s behavior, which can be used to forecast production rates, estimate recoverable reserves, and optimize extraction methods.

How Does Reservoir Simulation Software Work

Reservoir simulation software works through a series of steps, combining data integration, mathematical modeling, and computational processes.

1. Data Integration and Input

The first step in reservoir simulation involves gathering and integrating a wide range of data. This data is collected from multiple sources, including:

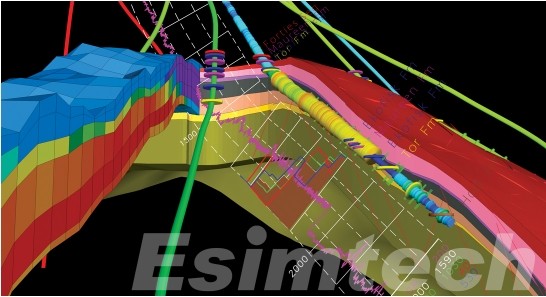

- Geological Data: Information about the rock formations, fault lines, and porosity of the reservoir. This data is often derived from seismic surveys, core samples, and well logs.

- Petrophysical Data: Details about the reservoir rock’s physical properties, including permeability, porosity, and fluid saturation.

- Fluid Data: Characteristics of the fluids in the reservoir (oil, gas, and water), such as viscosity, composition, and phase behavior at different pressures and temperatures.

- Production Data: Historical production rates, pressure changes, and well performance over time.

All of this data is essential for building a realistic representation of the reservoir and its fluid behavior. The input data is loaded into the simulation software to define the initial conditions and set up the model.

2. Mathematical Modeling

Once the input data is integrated, the software applies complex mathematical models to simulate fluid flow through porous media (the reservoir rock). The flow of fluids in reservoirs is governed by Darcy’s Law, which describes the movement of fluids through porous materials, as well as other physical laws that govern fluid mechanics, heat transfer, and thermodynamics.

The main mathematical models used in reservoir simulation are:

- Black Oil Model: A simplified model used for conventional oil reservoirs where fluid composition doesn’t change significantly with pressure. It models oil, gas, and water as three distinct phases.

- Compositional Model: This model simulates changes in fluid composition, typically used for gas-condensate and volatile oil reservoirs. It accounts for phase behavior based on pressure and temperature, providing a more detailed view of how hydrocarbons interact.

- Thermal Model: Applied in cases where temperature changes are significant, such as in enhanced oil recovery methods (e.g., steam injection). It simulates both fluid flow and heat transfer within the reservoir.

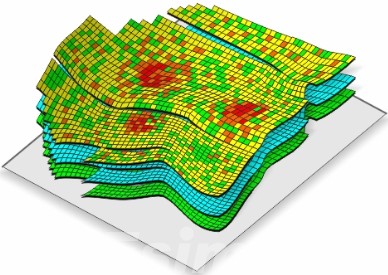

These models break the reservoir down into small, discrete cells in a process known as gridding. Each cell represents a portion of the reservoir, and the software calculates how fluids move from cell to cell over time based on the physical and chemical properties of the rock and fluids.

3. Simulation Process

With the model established, the simulation process begins. The software uses numerical methods, typically finite difference or finite element methods, to solve the complex partial differential equations that describe fluid flow and pressure distribution across the reservoir grid. The simulation calculates how fluids move through the reservoir over time, taking into account factors like:

- Fluid flow rates: The rate at which oil, gas, and water move through the reservoir rock.

- Pressure gradients: Changes in pressure within the reservoir, which drive fluid flow.

- Production and injection: The effects of extracting fluids from production wells or injecting fluids (like water or gas) to maintain reservoir pressure or enhance recovery.

The software performs these calculations repeatedly, often over a simulated time period of years or decades, to predict how the reservoir will behave under different scenarios.

4. History Matching

Once the initial simulation is complete, the model is fine-tuned through a process called history matching. In this step, the software compares the simulation results with actual production data to adjust the model and improve its accuracy. If the simulated results differ from real-world production rates or pressure trends, the model’s parameters are adjusted until the simulation closely matches the historical data.

History matching is an iterative process that helps ensure the simulation accurately reflects the reservoir’s true behavior, allowing for more reliable forecasts of future performance.

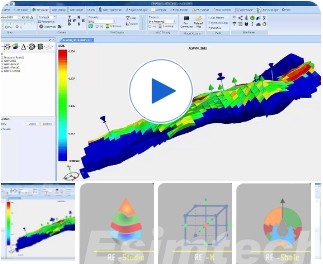

5. Scenario Analysis and Forecasting

After the model has been calibrated through history matching, engineers can run multiple scenarios to explore different production strategies, recovery techniques, or well placements. For example, the software can simulate:

- Natural depletion: Predicting how the reservoir will behave if production continues without any additional interventions.

- Enhanced Oil Recovery (EOR): Simulating the impact of various EOR methods, such as water flooding, gas injection, or steam injection, on production rates and recovery efficiency.

- Well placement optimization: Determining the best locations for new wells to maximize recovery or reduce risks.

The simulation provides forecasts for future production rates, reservoir pressure changes, and recovery factors, allowing engineers to evaluate the most effective development and recovery strategies.

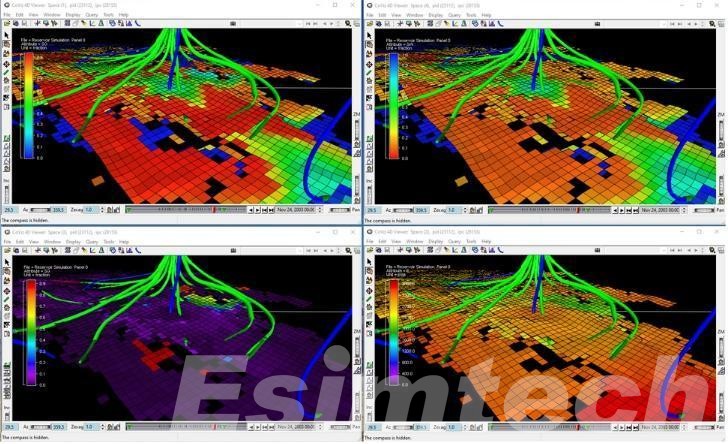

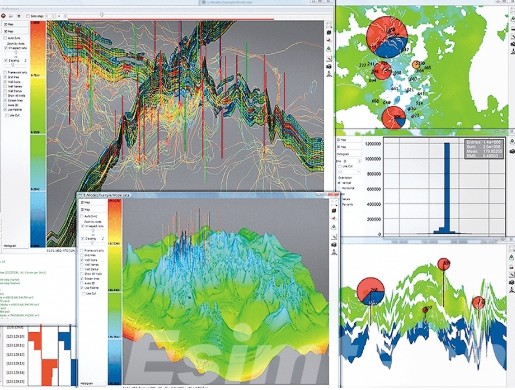

6. Visualization and Analysis

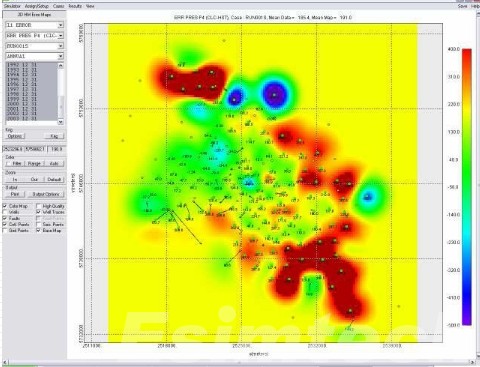

Modern reservoir simulation software comes with advanced 3D visualization simulation tools that help engineers and geoscientists better understand the reservoir’s behavior. These tools provide detailed images and animations of:

- Fluid distributions (oil, gas, water) across the reservoir.

- Pressure and temperature changes over time.

- The movement of injected fluids during EOR processes.

Visualization helps identify key trends and potential issues, such as areas of the reservoir that are underperforming or regions where water breakthrough might occur.

7. Optimization and Decision-Making

The final stage involves using the simulation results to optimize production strategies and make informed decisions. Reservoir engineers use the simulation outputs to:

- Maximize hydrocarbon recovery.

- Minimize operational costs and environmental impacts.

- Plan for future field development, including well placement and infrastructure needs.

By analyzing different scenarios, the software helps reduce uncertainty and risks, ensuring more efficient and effective reservoir management.

Applications of Reservoir Simulation Software

This chart highlights the diverse ways reservoir simulation software contributes to maximizing efficiency, reducing risks, and improving production strategies across oil and gas operations.

| Application | Description | Benefits |

| Field Development Planning | Simulating different production strategies to design optimal field development plans. | Maximizes hydrocarbon recovery, reduces risks, and optimizes well placement and infrastructure planning. |

| Production Forecasting | Predicting future production rates based on reservoir characteristics and proposed recovery methods. | Enables long-term financial planning and better decision-making for operational strategies. |

| Well Placement Optimization | Determining the best locations for new production or injection wells based on reservoir characteristics. | Increases well productivity and reduces drilling costs by minimizing non-productive zones. |

| Reservoir Management | Monitoring reservoir behavior over time, adjusting recovery strategies, and optimizing production performance. | Helps improve field efficiency, extend reservoir life, and enhance overall production management. |

| Unconventional Reservoirs | Simulating the unique challenges of tight formations, shale gas, or coalbed methane reservoirs. | Enhances recovery in unconventional resources by optimizing fracturing and stimulation techniques. |

| Risk Analysis | Simulating various production scenarios to assess operational risks and uncertainties. | Reduces uncertainty, helps mitigate operational risks, and supports informed investment decisions. |

| Reservoir Pressure Management | Evaluating the effect of different pressure maintenance techniques such as water or gas injection. | Ensures stable reservoir pressure, prolonging reservoir life and improving production efficiency. |

| Asset Valuation | Assisting in the economic evaluation of oil and gas assets by forecasting potential recovery and profitability. | Supports financial planning, investment decisions, and asset management strategies. |

Challenges and Future Trends in Reservoir Simulation Software

This chart outlines the current challenges faced in reservoir simulation and highlights the emerging trends that are shaping its future, focusing on efficiency, accuracy, cost-effectiveness, and sustainability.

| Challenges | Description | Future Trends | Description |

| Data Integration Complexity | Integrating diverse geological, petrophysical, and production data is difficult. | Improved Data Integration | Advanced AI-driven tools for seamless data integration from multiple sources, including real-time data. |

| High Computational Demand | Simulating large, complex reservoirs requires significant computational power. | Cloud Computing & High-Performance Computing | Utilization of cloud platforms and HPC to handle large-scale simulations faster and more efficiently. |

| Modeling Uncertainty | Uncertainty in geological and fluid properties leads to inaccurate predictions. | AI & Machine Learning for Uncertainty Reduction | AI and ML models to improve accuracy by learning from historical data and predicting uncertainties. |

| Cost of Simulation Tools | High cost of software licenses and computational resources. | Open-Source Simulation Software | Development of open-source platforms to reduce costs and increase accessibility. |

| Complexity in Unconventional Reservoirs | Modeling tight formations or fractured reservoirs is challenging. | Advanced Modeling for Unconventional Resources | New algorithms for handling complex reservoir behaviors in shale, tight gas, and other unconventional reservoirs. |

| Limited Real-Time Decision-Making | Real-time reservoir management is constrained by slow data processing. | Real-Time Reservoir Monitoring | Integration of IoT and real-time data analysis for dynamic, real-time decision-making in the field. |

| Difficulty in History Matching | The time-consuming process to adjust models based on historical data. | Automated History Matching | AI-powered automation for faster and more efficient history matching. |

| Environmental Concerns | Need for sustainability in reservoir management and minimizing environmental impact. | Sustainability-Focused Simulations | Development of models that consider environmental impact, such as carbon capture and storage (CCS). |

| Collaboration Between Disciplines | Effective communication between geoscientists, engineers, and economists is challenging. | Interdisciplinary Simulation Platforms | Platforms that integrate geophysical, economic, and engineering data to facilitate collaboration. |

| Limited Field Testing for New Technologies | New recovery methods and technologies are hard to test due to high costs. | Virtual Field Testing and Digital Twins | Simulation of new technologies through virtual field testing and the use of digital twin models. |

In summary, reservoir simulation software is indispensable in modern oil and gas exploration and production. It helps engineers make informed decisions, optimize production, and manage reservoirs effectively. As the technology continues to advance with AI & machine learning, cloud computing, open-source software, enhanced modeling capabilities, etc, reservoir simulation will play even more critical role in maximizing recovery from increasingly complex reservoirs.