The Critical Role of Horizontal Drilling Training in the Oil and Gas Industry: Key Techniques and How Simulation Technology Used in It

With the introduction of technologies such as horizontal drilling, the oil and gas industry has undergone a remarkable transformation. This novel method enables companies to gain access to unconventional reserves while optimizing hydrocarbon recovery. However, horizontal drilling in the oil and gas industry requires specialized knowledge and skills to be deployed successfully. In this article, we’ll explore the significance of horizontal drilling training in the oil and gas industry, focusing on the skills, techniques, benefits, and how simulation technology is used in horizontal drilling training.

Key Components of Horizontal Drilling Training

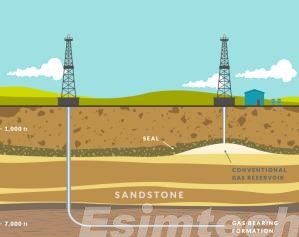

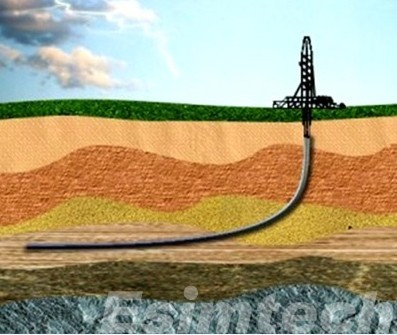

Horizontal drilling allows for the extraction of resources from reservoirs that were previously thought to be economically unviable. Horizontal drilling, as opposed to vertical wells, allows engineers to extend the wellbore laterally through the reservoir, increasing contact with hydrocarbon-bearing formations.

1. Advanced Drilling Techniques

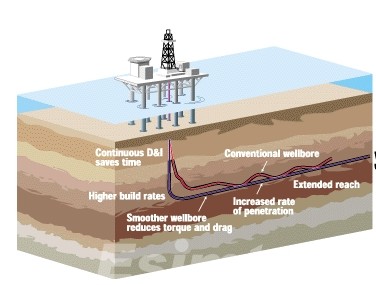

Advanced drilling techniques specific to the oil and gas industry are covered in horizontal drilling training. The use of rotary steerable systems, downhole motors, and other technologies that enable precise navigation through subsurface formations is included.

2. Well Planning and Design

Professionals must master the art of horizontal drilling well planning and design. This includes selecting optimal drilling locations, taking geological factors into account, and designing well trajectories to maximize reservoir contact.

3. Geological Understanding

A deep understanding of subsurface geology is essential. Training programs teach students how to interpret geological data, identify potential reservoirs, and make informed well placement decisions.

4. Risk Management

Horizontal drilling’s complexity introduces new risks. Training provides professionals with the knowledge and skills to effectively assess and manage these risks, ensuring the safety of personnel and the integrity of the drilling operation.

5. Drilling Equipment Operation

Horizontal drilling involves specialized equipment, such as measurement-while-drilling (MWD) tools and mud motors. To ensure smooth drilling operations, training programs focus on the operation, maintenance, and troubleshooting of these tools.

6. Safety Protocols

In the oil and gas industry, safety is of the utmost importance. Horizontal drilling training entails stringent safety protocols that cover everything from wellsite safety to emergency response procedures.

7. Regulatory Compliance

The oil and gas industry is governed by strict regulations. Training ensures that professionals understand regulatory requirements, reducing the risk of regulatory issues and legal challenges.

The Benefits of Horizontal Drilling Training

1. Enhanced Recovery Rates

Horizontal drilling improves hydrocarbon recovery rates significantly by increasing contact with reservoirs. Drilling strategies can be optimized by trained professionals to maximize production efficiency.

2. Reduced Environmental Impact

Well-trained personnel can employ horizontal drilling techniques to minimize surface disruptions. This is particularly important in environmentally sensitive areas where traditional vertical drilling might be impractical or ecologically harmful.

3. Economic Efficiency

While horizontal drilling has higher upfront costs, the long-term economic benefits frequently outweigh these costs. Trained professionals can contribute to cost-effective drilling programs, optimizing resource recovery over the life of the well.

4. Technological Advancements

Ongoing training ensures that professionals stay abreast of technological advancements in horizontal drilling. This knowledge is vital for adopting the latest tools and techniques that can further improve drilling efficiency.

The Role of Simulation Technology in Horizontal Drilling Training

In the dynamic landscape of the oil and gas industry, where precision and safety are paramount, simulation technology has emerged as a powerful tool in training professionals for the complexities of horizontal drilling. The intricate nature of drilling operations demands a hands-on understanding that goes beyond theoretical knowledge. Simulation technology used in horizontal drilling training, provides a realistic and risk-free environment for professionals to hone their skills.

The Significance of Simulation in Horizontal Drilling Training

- Realistic Wellbore Scenarios

Trainees can practice realistic wellbore scenarios thanks to simulation technology. Virtual environments simulate the difficulties of drilling through various geological formations, allowing professionals to understand the complexities of well planning and execution.

- Interactive Learning

Drilling and well control simulation system provides a hands-on learning experience. Trainees can take part in virtual drilling exercises, making decisions about trajectory planning, well placement, and equipment operation. This hands-on approach allows for a more in-depth understanding of the drilling process.

- Equipment Operation and Familiarization

Virtual simulations provide trainees with a safe and controlled environment in which to operate drilling equipment. Professionals can practice using specialized equipment, such as steering tools and measurement-while-drilling (MWD) systems, without the risks associated with live drilling operations.

- Risk Management Scenarios

Realistic risk scenarios can be created using simulation technology. Unexpected challenges such as wellbore instability, fluid loss, or equipment failures can be overcome by trainees.

- Dynamic Well Planning

Horizontal drilling requires meticulous planning. Professionals can use simulation software to dynamically plan wells in a variety of geological settings. Without the need for physical drilling, trainees can explore different trajectories, assess reservoir contact, and optimize well designs.

- Scenario Repetition and Skill Refinement

Simulation technology allows for the repetition of scenarios, allowing trainees to hone their skills. Repetition improves muscle memory and procedural familiarity, resulting in a more skilled and confident workforce.

- Emergency Response Training

Simulations serve as a training platform for emergency response personnel. In a controlled virtual environment, professionals can practice responding to well control incidents, blowouts, and other emergencies. This type of emergency simulation training is essential for ensuring a quick and effective response in real-life situations.

Features of Simulation Technology in Horizontal Drilling Training

- High-Fidelity Graphics

Advanced simulation tools offer high-fidelity graphics that recreate realistic drilling environments. This enhances the immersive experience, allowing trainees to feel as though they are actively engaged in a live drilling operation.

- Physics-Based Modeling

Simulation technology incorporates physics-based modeling to replicate the behavior of drilling equipment and wellbore interactions accurately. This ensures that trainees are exposed to realistic scenarios that mirror the challenges encountered in the field.

- Multi-User Collaboration

Some simulation platforms support multi-user collaboration, enabling teams to train together in a virtual space. This fosters communication and teamwork, essential components of successful drilling operations.

- Data Analytics and Performance Metrics

Simulation tools often include data analytics and performance metrics. Trainees can receive feedback on their decision-making processes, efficiency in equipment operation, and overall performance, allowing for continuous improvement.

Benefits of Simulation-Based Training in Horizontal Drilling

- Risk Mitigation

Simulation training reduces the risks associated with live drilling operations. Trainees can face and overcome challenges in a controlled environment, reducing the possibility of errors and accidents during actual drilling.

- Cost-Efficiency

The cost of live drilling operations is substantial. Simulation-based training is a more cost-effective option, allowing professionals to gain hands-on experience without the need for physical wells, equipment, and associated costs.

- Enhanced Learning Retention

Immersive and interactive experiences help to improve learning retention. When compared to traditional methods, simulation technology engages trainees, making the learning process more memorable and effective.

- Continuous Professional Development

Through simulation training, professionals in the oil and gas industry can engage in continuous professional development. As technology advances, simulation tools can be updated to reflect the most recent advancements, ensuring that the workforce remains at the cutting edge of industry innovation.

Conclusion

Horizontal drilling training is a critical component of success in the oil and gas industry’s pursuit of greater efficiency and sustainability. Professionals can navigate the complexities of horizontal drilling through comprehensive training programs, unlocking new frontiers, and optimizing the industry’s impact on global energy needs.

Simulation technology has evolved into an indispensable tool in the training arsenal of horizontal drilling professionals. Oil and gas simulation tools enable individuals to develop the skills and expertise required to navigate the complexities of horizontal drilling by providing an immersive and risk-free learning environment.