The Critical Role of Electric Submersible Pumps in the Oil and Gas Industry

Electric Submersible Pumps (ESPs) are pivotal in the oil and gas industry, enhancing the efficiency and productivity of hydrocarbon extraction. These pumps lift large volumes of fluids from wellbores to the surface, making them essential in various phases of oil and gas production. This article delves into the functionality, applications, challenges, and solutions associated with Electric Submersible Pumps in the oil and gas sector.

Functionality of Electric Submersible Pumps in the Oil and Gas Industry

Operations of ESP pump in the oil and gas industry is based on a robust and intricate design that ensures reliable performance in diverse and often challenging reservoir conditions.

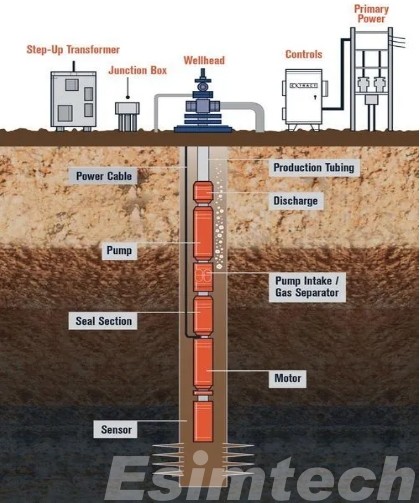

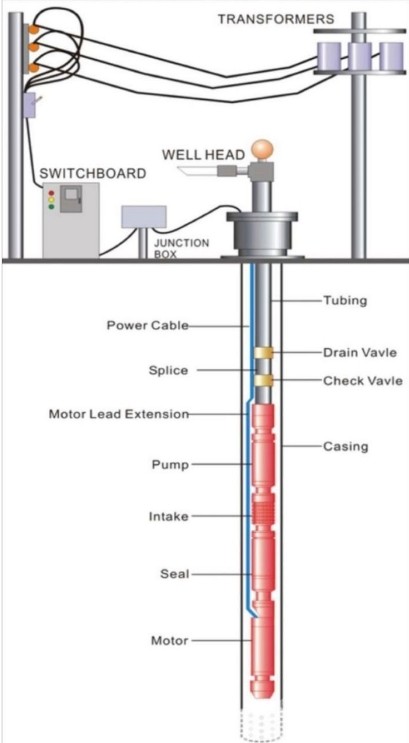

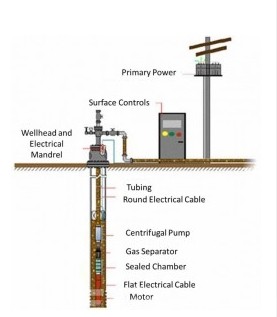

Components of an Electric Submersible Pump System

1. Pump

- Design: The pump consists of multiple stages of centrifugal impellers and diffusers. Each stage increases the pressure of the fluid being pumped.

- Operation: As the motor drives the impellers, fluid enters the pump intake and is sequentially pressurized through each stage. This multistage process allows the pump to lift fluids from deep within the wellbore to the surface.

2. Motor

- Type: The motor used in ESP systems is typically a three-phase induction motor.

- Cooling and Lubrication: It is filled with dielectric oil, which serves to cool the motor and lubricate its internal components.

- Placement: Positioned below the pump, the motor provides the necessary mechanical energy to drive the pump.

3. Seal Section

- Function: The seal section, also known as the protector, is crucial for protecting the motor from well fluids and pressure.

- Features: It compensates for the thermal expansion and contraction of the motor oil and prevents the ingress of well fluids, ensuring the motor’s longevity and reliability.

4. Power Cable

- Design: The power cable is designed to withstand harsh downhole conditions, including high temperatures and pressures.

- Function: It transmits electrical power from the surface to the submersible motor, enabling the pump’s operation.

5. Surface Control System

- Components: This system includes a variable speed drive (VSD), a transformer, and monitoring equipment.

- Function: The VSD allows operators to adjust the pump’s speed and optimize its performance based on real-time data. The surface control system also monitors various parameters such as pressure, temperature, and flow rates, ensuring efficient and safe operation.

Operational Mechanism

1. Fluid Intake

- Process: Fluid from the reservoir enters the pump through the intake section, typically located at the bottom of the pump assembly.

2. Pressurization and Lifting

- Centrifugal Force: The rotating impellers impart kinetic energy to the fluid, converting it to pressure energy in the diffusers.

- Stage-by-Stage Pressure Increase: As fluid moves through each stage, its pressure increases progressively. The cumulative effect of multiple stages results in significant pressure elevation, sufficient to lift the fluid to the surface.

3. Cooling and Lubrication

- Motor Cooling: The dielectric oil within the motor facilitates effective cooling, preventing overheating and ensuring continuous operation.

- Lubrication: This oil also lubricates the motor’s bearings and internal components, reducing wear and extending the motor’s lifespan.

4. Control and Monitoring

- Surface Adjustments: Operators can make real-time adjustments to the pump’s operation via the surface control system, optimizing performance based on changing well conditions.

- Data Monitoring: Continuous monitoring of operational data allows for early detection of issues such as gas lock, scaling, or mechanical wear, enabling prompt intervention and maintenance.

Applications of Electric Submersible Pumps in the Oil and Gas Industry

This chart provides a concise overview of the diverse applications of ESPs in the oil and gas industry, highlighting their role in enhancing production efficiency and maintaining consistent fluid lifting in various operational scenarios.

| Application | Description | Benefits |

| Primary Recovery | The initial phase of oil production where natural reservoir pressure drives fluids to the surface. | Efficient fluid lifting, maximizing initial production. |

| Secondary Recovery | Enhanced oil recovery techniques such as waterflooding or gas injection to maintain reservoir pressure. | Sustained production rates, and improved recovery efficiency. |

| Enhanced Oil Recovery (EOR) | Advanced techniques like steam-assisted gravity drainage (SAGD), polymer flooding, and thermal recovery. | Handles increased fluid volumes, and improves oil recovery. |

| Offshore Operations | Extraction of oil and gas in offshore fields where conditions are more challenging. | Reliable operation in deepwater, high-pressure environments. |

| Deepwater Operations | Operations in ultra-deepwater oil drilling fields, often at depths exceeding 1,500 meters. | Efficient fluid lifting from extreme depths. |

| Heavy Oil Production | Extraction of heavy, viscous oil which requires specialized equipment for efficient lifting. | Handles high-viscosity fluids, and improves heavy oil recovery. |

| Artificial Lift in Mature Wells | Using ESPs to maintain production levels in wells where natural pressure has declined. | Extends economic life of mature wells. |

| Gas Wells | De-watering gas wells to enhance gas production by removing liquids that hinder gas flow. | Increases gas production rates, and prevents liquid loading. |

| Unconventional Resources | Extraction from unconventional reservoirs like shale and tight formations using hydraulic fracturing. | Supports high flow rates, adaptable to varying conditions. |

Challenges and Solutions Associated with Electric Submersible Pumps in the Oil and Gas Industry

1. Installation and Maintenance

Challenges

- Complex Installation: The installation of Electric Submersible Pumps can be complex, requiring specialized equipment and expertise.

- Maintenance Issues: ESPs require regular maintenance to ensure optimal performance, which can be challenging, especially in remote or offshore locations.

Solutions

- Expert Training: Providing comprehensive training for installation and maintenance crews to ensure they are skilled in handling ESP systems.

- Advanced Tools: Utilizing advanced installation tools and technologies to simplify the installation process and reduce downtime.

- Predictive Maintenance: Implementing predictive maintenance strategies using data analytics to anticipate potential failures and perform maintenance before issues arise.

2. Scale and Corrosion

Challenges

- Scaling: Mineral deposits can form on the pump components, reducing efficiency and potentially causing failures.

- Corrosion: Corrosive fluids can damage pump components, leading to leaks and mechanical failures.

Solutions

- Chemical Treatments: Regularly treating the well with scale inhibitors and corrosion inhibitors to prevent deposit formation and material degradation.

- Material Selection: Using corrosion-resistant materials such as stainless steel or specialized coatings for pump components to enhance durability.

- Routine Cleaning: Scheduling periodic cleaning of the pump to remove any build-up of scale or corrosive materials.

3. Power Supply Issues

Challenges

- Remote Locations: Ensuring a reliable power supply in remote or offshore locations can be difficult.

- Power Fluctuations: Inconsistent power supply can lead to motor failures and reduced pump efficiency.

Solutions

- Backup Power Systems: Installing backup power systems, such as generators or battery storage, to provide a reliable power source in remote locations.

- Voltage Regulators: Using voltage regulators and uninterruptible power supplies (UPS) to stabilize power supply and protect the Electric Submersible Pump system from power fluctuations.

- Renewable Energy: Exploring renewable energy sources integrated in the oil and gas exploration, such as solar or wind, to supplement traditional power supplies in remote areas.

4. Reservoir Conditions

Challenges

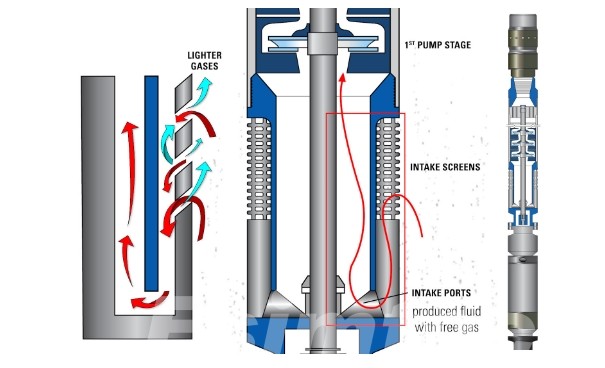

- Gas Lock: The presence of gas in the fluid can cause a gas lock, where the pump becomes gas-bound and loses its ability to lift fluids.

- Sand Production: Sand and other particulates can cause abrasion and clogging, leading to reduced pump efficiency and potential failures.

Solutions

- Gas Separators: Installing gas separators or gas handlers above the pump intake to prevent gas from entering the pump and causing a gas lock.

- Sand Control: Implementing sand control measures, such as gravel packing or sand screens, to prevent sand from entering the well and damaging the pump.

- Adaptive Control Systems: Utilizing adaptive control systems to monitor well conditions and adjust pump operation in real time to handle changing conditions.

5. High Temperatures and Pressures

Challenges

- Extreme Conditions: High temperatures and pressures in deep wells can stress pump components and lead to premature failures.

- Thermal Expansion: Temperature fluctuations can cause thermal expansion and contraction, impacting the pump’s performance and integrity.

Solutions

- High-Temperature Materials: Using materials and components designed to withstand high temperatures and pressures, such as high-strength alloys and advanced ceramics.

- Thermal Management: Implementing thermal management solutions, such as insulating materials and cooling systems, to maintain stable operating temperatures.

- Pressure Monitoring: Continuously monitoring pressure levels and using pressure relief systems to protect the pump from pressure spikes.

How Simulations are Used for Electric Submersible Pumps in the Oil and Gas Industry

1. Design and Optimization

a. Performance Modeling

- Objective: To predict the performance of ESP pumps under various operational conditions.

- Process: Engineers use computational fluid dynamics (CFD) simulations to model the flow of fluids through the pump stages. These simulations help in understanding how different designs impact efficiency, pressure, and flow rates.

- Outcome: Optimization of impeller and diffuser designs to achieve maximum efficiency and reliability.

b. Material Selection

- Objective: To choose materials that can withstand the harsh conditions of oil and gas wells.

- Process: Simulations are used to evaluate the mechanical and chemical properties of different materials under high temperatures, pressures, and corrosive environments.

- Outcome: Selection of the most suitable materials that offer durability and performance in specific well conditions.

2. Operational Management

a. Predictive Maintenance

- Objective: To predict potential failures and schedule maintenance proactively.

- Process: Simulations analyze data from sensors and historical performance to predict wear and tear on components. Machine learning algorithms are often integrated into these simulations to improve prediction accuracy.

- Outcome: Reduced downtime and maintenance costs by addressing issues before they lead to failures.

b. Performance Monitoring

- Objective: To monitor and optimize the real-time performance of ESP systems.

- Process: Real-time data from the ESPs is fed into simulation models that predict the optimal operating conditions. These simulations account for variables such as fluid composition, pressure, and temperature.

- Outcome: Adjustments can be made to operating parameters to maintain optimal performance and extend the lifespan of the pumps.

3. Training and Safety

a. Virtual Training

- Objective: To train engineers and technicians in the installation, operation, and maintenance of ESPs.

- Process: Virtual reality (VR) training simulations create realistic scenarios where trainees can practice without the risks associated with real-world operations.

- Outcome: Improved skills and knowledge, leading to safer and more efficient operations.

b. Safety Simulations

Objective: To ensure safety protocols are effective and to prepare for emergency situations.

Process: Emergency training simulations model potential failure scenarios and the impact of different emergency responses.

Outcome: Enhanced preparedness and response strategies, reducing the risk of accidents and equipment damage.

4. Reservoir and Production Management

a. Integrated Reservoir Modeling

- Objective: To optimize the placement and operation of ESPs within the reservoir.

- Process: Reservoir simulations model the flow of fluids within the reservoir and predict how different ESP configurations will affect production rates.

- Outcome: Optimal placement and operation of ESPs to maximize hydrocarbon recovery.

b. Production Forecasting

- Objective: To predict future production rates and plan accordingly.

- Process: Simulations integrate geological data, reservoir characteristics, and ESP pump performance to forecast production.

- Outcome: Better planning and decision-making to maximize production efficiency and economic returns.

Conclusion

Electric Submersible Pumps have revolutionized the oil and gas industry by providing an efficient and reliable method for lifting fluids from wellbores to the surface. Their adaptability to various well conditions and ability to handle large fluid volumes make them indispensable in modern hydrocarbon extraction. However, successful deployment and operation of ESPs require careful consideration of installation, maintenance, and reservoir management challenges.

Simulations play a vital role in the design, optimization, and operational management of Electric Submersible Pumps in the oil and gas industry. They provide valuable insights and predictive capabilities that help engineers and operators enhance the performance and reliability of ESP pump systems.